Abstract

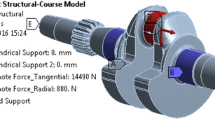

Among the most critical components, crankcase the housing for the crankshaft is used for effective and precise working of the internal combustion engine. The main aim of this work is to analyze the structural and modal parameters of the crankcase of diesel engine of existing and modified model. Solid model of the crankcase is generated using the commercially available software packages, as per the dimensional details of existing crankcase. Static and vibrational analysis of the crankcase is carried out using commercially available software packages for the boundary conditions in accordance with engine specifications and mounting conditions. The modified model of the crankcase is also modeled, analyzed and compared with the existing model of the crankcase. The modified model is prepared for the experimentation using the fast fourier transformer (FFT) analyzer. Simulation results show that the modified model of the crankcase demonstrates the reduced stresses (by 10%) and deformation by (40%) with the existing model also absorb more vibrations.

Similar content being viewed by others

References

G.A.Bhosale VVK Static analysis of crankcase for single cylinder high speed diesel engine. Int. J. Latest Trends Eng. Technol. 6, 395–402 (2015)

B.D.Sawant GAB Modal analysis of crankcase for single cylinder high speed diesel engine. Int. J. Latest Trends Eng. Technol. 9, 55–60 (2017). https://doi.org/10.21172/1.91.08

Bayrakçeken, H., Tasgetiren, S., Aksoy, F.: Failures of single cylinder diesel engines crank shafts. Eng. Fail. Anal. 14, 725–730 (2007). https://doi.org/10.1016/j.engfailanal.2006.01.006

Patnaik, L., Saravanan, I., Kumar, S.: Materials today : proceedings die casting parameters and simulations for crankcase of automobile using MAGMAsoft. Mater. Today Proc. 22, 563–571 (2020). https://doi.org/10.1016/j.matpr.2019.08.208

Schöffmann, W., Beste, F., Atzwanger, M.: Lightweight engine structures—Crankcase concepts for high-performance diesel engines. ATZautotechnology 2, 50–53 (2002). https://doi.org/10.1007/bf03246726

Shahane, V.C., Pawa, R.S.: Optimization of the crankshaft using finite element analysis approach. Automot. Engine Technol. 2, 1–23 (2017). https://doi.org/10.1007/s41104-016-0014-0

Espadafor, F.J., Villanueva, J.B., García, M.T., Trujillo, E.C.: Analysis of a diesel generator cylinder failure. Eng. Fail. Anal. 17, 913–925 (2010). https://doi.org/10.1016/j.engfailanal.2009.11.003

Fonte, M., Duarte, P., Reis, L., et al.: Failure mode analysis of two crankshafts of a single cylinder diesel engine. Eng. Fail. Anal. 56, 185–193 (2015). https://doi.org/10.1016/j.engfailanal.2015.02.014

Fonte, M., de Freitas, M.: Marine main engine crankshaft failure analysis: a case study. Eng. Fail. Anal. 16, 1940–1947 (2009). https://doi.org/10.1016/j.engfailanal.2008.10.013

Chavan, P.M.: Design & Analysis of Crankshaft for Single Cylinder Diesel Engine. 1311–1319 (2021)

Joshi, P.P., Ghorpade, R.R., Birari, A.B.: Design and analysis of zero coupled compressor crankcase. Int. J. Sci. Technol. Res. 8, 1036–1042 (2019)

Swathi, N., PRH and DAP.: Design and weight optimization of crankcase of a reciprocating compressor. IPASJ Int. J. Mech. Eng. 2, 79–84 (2014)

Zhaokun, Xu., Sun Shu Ting, W.W.: Vibration analysis and the location of balance shaft on four-cylinder engine. Noise Vib. Control 6, 50–53 (2007)

Sagar Sonone, A.C.: Design and analysis of balancer shaft for a four stroke single cylinder diesel engine. Int. J. Eng. Res. Technol. 4, 828–832 (2015)

Yu, F., Xie, J., Xu, Z.M.: The vibration reduction design of single-cylinder engine based on the balance shaft. Vibroeng. Proc. 23, 18–23 (2019)

Sowjanya, G.P., Rao, P.D., Kiran, D.C.U.: Finite element analysis of vibration fixture made of aluminum and magnesium alloys. Int. J. Latest Trends Eng. Technol. (IJLTET) 2, 84–89 (2013)

Chaudhari, P.B., Panchagade, D.D.: Comparison of magnesium, aluminium and cast iron to obtain optimum frequency for engine bracket using finite element analysis. Int. J. Eng. Appl. 2, 1016–1020 (2012)

Naghate, S., Patil, S.: Modal analysis of engine mounting bracket using FEA. Int. J. Eng. Res. Appl. 2, 1973–1979 (2012)

Karthikeyan, S., Sathyanandan, M., Krishnan, S.: Design enhancement of EGR system for improved vibration performance on truck diesel engine. Int. J. Adv. Des. Manuf. Technol. 7(1), 8 (2014)

Taj, A., Doddamani, S., Vijaykumar, T.N.: Vibrational analysis of aluminium graphite metal matrix composite. Int. J. Eng. Res. Technol. 6, 1072–1078 (2017)

Salunkhe, P., Dhummansure, V.K., Babar, S.R.: Failure co-relation and strength optimization of EGR cooler housing for diesel engine. Int. J. Innov. Res. Sci. Eng. Technol. 4, 1–10 (2015)

Vishalkumar, K., Dhummansure, D.R.R.: Structural modifications in diesel engine components to reduce noise. Int. J. Mech. Eng. Technol. 9, 1067–1073 (2018)

Vishalkumar, K., Dhummansure, D.R.R., Yogesh, B.: Cam profile optimization of single cylinder diesel engine to reduce noise and vibration. Int. J. Mech. Prod. Eng. Res. Dev. 8, 759–770 (2018)

Dhummansure, V.K., Salunkhe, P.S., Saleemsab Doddamani, N.I.J.: Structural analysis and optimization of EGR cooler for diesel engine. J. Fail. Anal. Prev. Springer 21, 1387–1395 (2021). https://doi.org/10.1007/s11668-021-01191-x

IS 210 (2009) Indian Standard Grey Iron Castings – Specification (Fifth Revision)

Wang, E., TN and RR: A comparison of all-Hexahedra and all Tetrahedral Finite Element Meshes for elastic analysis. In: Proceedings 4th of international conference. pp 179–181 (1995).

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dhummansure, V., Doddamani, S., Jamadar, N.I. et al. Structural and modal analysis of crankcase of single cylinder diesel engine. Int J Interact Des Manuf 17, 1215–1223 (2023). https://doi.org/10.1007/s12008-022-01101-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-01101-x