Abstract

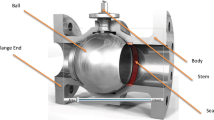

The application of a gate valve is to make a straight-inline flow of fluid with less restriction as the turbulence is created through the aperture provided in the valve body. The change in direction of the fluid creates change on the operating stress of the vale body. The paper is targeted for designing the valve body for reduction in the overall weight of the body and making it light in weight. The optimized design keeps the operating stress with operating stress within change of 5% which thereby ensures that the original stress value is not altered much. In the current manuscript the ribs of various thicknesses are proposed those are to be welded across the outer periphery of the body. The ribs provided on the periphery are substitutes for the reduction in the weight. The sensitivity analysis along with the change in the materials is analyzed in the manuscript. The complete optimization is valve body is done by topology optimization tool in ANSYS. This paper help and give an aim for researchers on optimizing the gate valve body with help of finite element analysis (FEA) and optimized design by adding ribs to the gate valve body to reduce the stress and deformation.

Similar content being viewed by others

References

Babcock and Wilcox, Steam, Its Generation and Use, Babcock & Wilcox Co., Cheremisinoff, N. P., Fluid Flow, Pumps, Pipes and Channels, Ann Arbor Science (1978)

Physics Corporation, Library of congress card #A 326517, (1982)

Stewart, L.H.: Pneumatics and Hydraulics. Theodore Audel and Company (1984)

He, X., Zhang, C., Tian, D.: Strength analysis and structure optimization of gate valve body based on finite element software. E3S Web Conf. EDP Sci. 136, 03019 (2019)

Liu, X., Zhao, G., Luo, Xl., Zhang, N., Huang, X.: Research on green design of valve products based on response surface method. In: Scholz, S.G., Howlett, R.J., Setchi, R. (eds.) Sustainable design and manufacturing 2020. Smart Innovation, Systems and Technologies, Springer, Singapore (2021)

Zakirnichnaya, M.M., Kulsharipov, I.M.: Wedge gate valves selecting essentials in pipeline systems designing based on permissible operation parameters. IOP Conf. Ser.: Earth Environ. Sci. 87(8), 082055 (2017)

Shivaji, D.S., DharmaraoSumit, S.: Stress analysis of gate valve by ansys. DAV Int. J. Sci. 3(1), 33–41 (2014)

Mattsson, E., Svensson, L.: Corrosion investigation of valves in flowing sea water. Br. Corros. J. 7(5), 200–207 (1972)

Kim, D.W., Park, S.G., Lee, S.G., Kang, S.C.: A study on a characteristic of stem friction coefficient for motor operated flexible wedge gate valve. Nucl. Eng. Des. 239(10), 1744–1749 (2009)

Sathishkumar, S., Hemanathan, R., Gopinath, R., Dilipkumar, D.: Design and analysis of gate valve body and seat ring. Int. J. Mech. Eng. Technol. 8(3), 131–141 (2017)

Fertahi, S., Bouhal, T., Arid, A., et al.: Thermo-mechanical strength analysis for energy storage improvement of horizontal storage tanks integrating evacuated tube collectors. Int. J. Hydrogen Energy 42, 29370–29383 (2017)

Alonso, D., De, S., Saenz, J., et al.: Topology optimization applied to the design of 2D swirl flow devices. Struct. Multidiscip. Optim. 58, 2341–2364 (2018)

Khurmi, R.S., Gupta, J.K.: A textbook of machine design. S Chand and Company Ltd, Chanai (2005)

Bhandari, V.B.: Design of machine elements. Tata Mc-Graw Hill Publication, NY (2022)

Minhas, A., Patel, S., Kazerooni, E., et al.: Iterative reconstruction results in larger computed tomography measurements of iliofemoral artery diameter in patients referred for transcatheter aortic valve replacement. J. Comput. Assist. Tomogr. 40, 773–776 (2016)

Sumit, D.: Stress analysis of gate valve by ANSYS. DAV Int. J. Sci. 3, 33–41 (2013)

Mahomed, N., Kleynhans, H.: Reducing shrinkage porosity in high-performance steel castings: case of an ASME B16.34 gate valve body: Part 1—analysis, techniques and experimental approach. Int. J. Metal Casting 12, 919–926 (2018)

Mahmoodi, K., Ghassemi, H., Nowruzi, H., et al.: Prediction of the hydrodynamic performance and cavitation volume of the marine propeller using gene expression programming. Ships Offshore Struct. 14, 723–736 (2019)

Lokhande, S.W., Langde, A.M.: Optimization of industrial valve design considering flow parameter using CFD. IJIRSET 5(6), 218 (2016)

Gurav, S.S., Patil, S.A.: Weight optimisation of 12–600 gate valve by using finite element analysis and experimental stress analysis-a review. Res. Inventy: Int. J. Eng. Sci. 4(9), 31–32 (2014)

Jatkar, K.H., Dhanwe S.S.: Finite Element Analysis of gate Valve. Asian Rev. Mech. Eng. 2, 44–49 (2013). https://doi.org/10.51983/arme-2013.2.1.2324

Li, S., Li, L., Hou, Y.: Seal Analysis and Optimization of Large Diameter gate Valve Based on ANSYS. Appl. Mech. Mater. 415, 498–501 (2013). https://doi.org/10.1051/e3sconf/201913603019

Xiaoke, He, Chenzun, Zhang, Ding, Tian.: Strength analysis and structure optimization of gate valve body based on finite element software, farmland irrigation research institute. CAAS (2019)

Paul, P.E.S., Kumar G.U., Durairaj S., Sundarrajan, D.: Design and analysis of industrial ball valve using computational fluid dynamics. Int. J. Recent Trends Mech. Eng. IJRTME-ISSN: 2347–7326 (2015)

Boye, T.G.E., Olabisi, A.I., Nwaoha T.C.: Finite element analysis and design validation of high-pressure gate valve for a typical nigerian oil wellhead. J. Multidiscip. Eng. Sci. Technol. JMEST (2016). https://www.researchgate.net/publication/306396319

Raji, A.O.Y., Abejide, T.S.: An assessment of environmental problems associated with oil pollution and gas flaring in the Niger delta region C 1960–2000 Arabian. J. Bus. Manag. Rev. 3(3), 115 (2013)

Sahni, G., Singh, B.: To perform the structural analysis on wedge type gate valve and its optimization using F.E.A. IRJMST 88, 277–281 (2014)

Pujari, A.A., Joshi, G.S.: Analysisand design optimization of 8–600# gate valve body using fea and stress analysis. IJRET Int. J. Res. Eng. Technol. 04(02), 154 (2015)

Schweitzer, P.A.: Handbook of valves. New York Industrial Press, NY (1972)

Cheng, Y.: Cheng basic knowledge of valves, 1st edn. Publisher Tongling Education Press, China (2008)

Mantati, S., Surde, A.N.: Finite element analysis of flexible wedge type (2#150) gate valve. Int. J. Emerg. Technol. Adv. Eng. 5(6), 195–198 (2015)

Zhanga, Y., Zhao, S., Zhang, Z.: Optimization for the forming process parameters of thin-walled valve shell, School of mechanical engineering, Xi’an Jiao Tong University, Xi’an 710049, China. School of mechanical and electrical engineering, Inner Mongolia Agriculture University, Inner Mongolia 010018, China. Thin Walled Structure 46, 371–379 (2008)

Barboza Neto, E.S., Chludzinski, M., Roese, P.B., Fonseca, J.S.O., Amico, S.C., Ferreira, C.A.: Experimental and numerical analysis of a LLDPE/HDPE liner for a composite pressure vessel, ELSEVIR. Polym. Test. 30, 693–700 (2011)

Prabu, B., Rathinam, N., Srinivasan, R., Naarayen, K.A.S.: Finite element analysis of buckling of thin cylindrical shell subjected to uniform external pressure. Department of mechanical engineering, Pondicherry engineering college, Pondicherry-605014 India. J. Solid Mech. 1, 148–158 (2009)

Nermina Zaimović-Uzunovi ć, Ejub Ajan, Samir Emeš.: Weight optimization of the butterfly valve housing. in 10th International research/expert conference trends in the development of machinery and associated technology TMT 2006, Barcelona-Lloret de Mar, Spain, 11–15 (2006)

Rao, J.S., Vasantha B.K.: Weight optimization of turbine blades. Copyright Altair Eng. Inc. 1–19 (2011) https://www.researchgate.net/publication/228805644

Sila, S.P., Pereira, R.F.P., Abreu, G.A., Panzera, T.H., Brandão CR.: Machining optimization of sleeve and valves of hydraulic steering system, in Proceedings of the world congress on engineering 2010, Vol III WCE2010, London, (2010)

Golbabaei-Asl, M., Torabi, R., Nourbakhsh, S.A., Sedighiani, K.: Failure Detectionand optimization of a centrifugal-pump volute casing. In: Proceedings of the SEM annual conference, Albuquerque, New Mexico, USA (2009)

Pradnyawant, K.P., Laukik, B.R.: Weight optimization of 12–150 class plug valve casting body by finite element analysis. Int. J. Eng. Res. Technol. (IJERT) 3(12), 2278–181 (2014)

Prabhala, S.K., Kumar, K.S.R.: Design and weight optimization of IC engine. E-ISSN 2249–8974, 56–58 (2012)

Saood, A., Khan, A.H., Equbal, M.I., Saxena, K.K., Prakash, C., Vatin, N.I., Dixit, S.: Influence of fiber angle on steady-state response of laminated composite rectangular plates. Materials 15, 5559 (2022). https://doi.org/10.3390/ma15165559

Hashmi, A.W., Mali, H.S., Meena, A., Saxena, K.K., Puerta, A.P.V., Prakash, C., Buddhi, D., Davim, J.P., Abdul-Zahra, D.S.: Understanding the mechanism of abrasive-based finishing processes using mathematical modeling and numerical simulation. Metals 12, 1328 (2022). https://doi.org/10.3390/met12081328

Upadhyay, G., Saxena, K.K., Sehgal, S., Mohammed, K.A., Prakash, C., Dixit, S., Buddhi, D.: Development of carbon nanotube (CNT)-reinforced Mg alloys: fabrication routes and mechanical properties. Metals 12, 1392 (2022). https://doi.org/10.3390/met12081392

Arora, G.S., Saxena, K.K., Mohammed, K.A., Prakash, C., Dixit, S.: Manufacturing techniques for Mg-based metal matrix composite with different reinforcements. Curr. Comput.-Aided Drug Des. 12, 945 (2022). https://doi.org/10.3390/cryst12070945

Naveenkumar, R., Shankar, S., Nithyaprakash, R., et al.: Evaluation of the efficacy in ergonomically designed handsaw to minimize the muscular load on arm and shoulder muscles among carpenters. J. Inst. Eng. India Ser. C (2022). https://doi.org/10.1007/s40032-022-00858-0

Mondal, A., Chatterjee, S., Sahu, A.K., Mahapatra, S.S., Prakash, C.: Analysis of machining parameters in drilling of biocompatible composite: HAp-HDPE and HAp-UHMWPE. In: Prakash, C., Singh, S., Ramakrishna, S. (eds.) Additive, subtractive, and hybrid technologies. Mechanical engineering series. Springer, Cham (2022)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kansara, P., Indrodia, A., Diwan, M. et al. Optimization of gate valve structure based on strength parameters using finite element analysis. Int J Interact Des Manuf 17, 2541–2549 (2023). https://doi.org/10.1007/s12008-022-01052-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-01052-3