Abstract

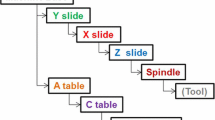

Programs for 5 axis machining is not complex task but also tedious to understand and implement for new CNC programmers. Hence for making the concept of 5-axis easy for understanding at zero damage of the machine tool it is necessary for developing virtual platform which will give real time feel of the actual CNC machine. The concept of 5 axis simultaneous machining is not as the same as that of the 3 axis programming as there is two more axis operating simultaneously. This constraint makes 5 axis program is bit complex for the new programmers it is needed to be done in virtual environment. This paper explains a systematic procedure of developing a virtual 5 axis machine tool in PLM platform (Product lifecycle Management). This virtual platform is not only used for training purpose but also for identifying collision detection between the machine components and work piece. Standard procedure is applied to 5-axis table-table configuration builded in SIEMENS NX 12 software. This process implies 3 major steps. The first step is simplifying the hierarchy based kinematic chain. The second step implies assignment of specific movements of the machine components. The last step is the assignment of the virtual controller and its respective post processor. On completion of the above procedure validation is done by same by generating by the 5 axis program on gear bracket component.

Similar content being viewed by others

References

Sanchez Gomez, C.A., Gil Castiblanco, L.E., Arroyo Osorio, J.M.: Building a virtual machine tool in a standard PLM platform. Int. J. Interact. Des. Manuf. 11(2), 445–455 (2017). https://doi.org/10.1007/s12008-016-0312-9

Guerra-zubiaga, D.A., Contero, M., Orta, P., Molina, A., Guerra, D., Contero, M., Orta, P., Molina, A.: Industrial applications of PLM: Automotive and aerospace sectors. In: Proceedings of Virtual Concept. pp. 1–4. Springer-Verlag (2006).

Gandhi, P.S., Deshmukh, S.: A 2D optomechanical focused laser spot scanner : analysis and experimental results for microstereolithography P S Gandhi and S Deshmukh. J. MIicromechanics Microengineering. 015035, 1–11 (2009). https://doi.org/10.1088/0960-1317/20/1/015035

Deshmukh, S., Gandhi, P.S.: Optomechanical scanning systems for microstereolithography ( MSL ): analysis and experimental verification. J. Mater. Process. Technol. 9(209), 1275–1285 (2009). https://doi.org/10.1016/j.jmatprotec.2008.03.056

Chan, D.S.K.: Simulation modelling in virtual manufacturing analysis for integrated product and process design. Assem. Autom. 23(1), 69–74 (2003). https://doi.org/10.1108/01445150310460114

Fischer, X., Coutellier, D.: The interaction: a newway of designing. In: Fischer, X., Coutellier, D. (eds.) Research in Interactive Design, pp. 1–15. Springer, France (2006)

Abdul Kadir, A., Xu, X., Hämmerle, E.: Virtual machine tools and virtual machining-A technological review. Robot. Comput. Integr. Manuf. 27(3), 494–508 (2011). https://doi.org/10.1016/j.rcim.2010.10.003

Kumar, K., Zindani, D., Davim, J.P.: Introduction to Virtual Manufacturing. In: Advanced Machining and Manufacturing Processes. pp. 169–180. Springer, Cham (2018). https://doi.org/10.1007/978-3-319-76075-9_11.

Altintas, Y., Brecher, C., Week, M., Witt, S.: Virtual machine tool. CIRP Ann. (2005). https://doi.org/10.1016/s0007-8506(07)60022-5

Shinde, S.M., Lekurwale, R.R.: Radial stiffness computation of single Archimedes spiral plane supporting spring loaded in flexural mechanism mounted in spindle head of micro drilling machine tool. Mech. Based Des. Struct. Mach. 1(5), 1–21 (2022). https://doi.org/10.1080/15397734.2022.2040363

Shinde, S.M., Lekurwale, R.: Design and development of three leg spiral curve flexural cartridge for micro drilling spindle head : a novel mechanism. Int. J. Mechatronics Manuf. Syst. 14(1), 55–82 (2021). https://doi.org/10.1504/IJMMS.2021.115463

Shinde, S.M., Lekurwale, R.: Experimental and numerical investigation of difference in diameter enlargement and circularity of micro-holes drilled by flexural spindle head. J. Micromanufacturing. 3(2), 21–41 (2020). https://doi.org/10.1177/2516598420964049

Shinde, S.M., Lekurwale, R.R.: Synthesising of flexural spindle head micro drilling machine tool in PLM environment. Int. J. Virtual Technol. Multimed. 1(3), 246 (2021). https://doi.org/10.1504/ijvtm.2021.119818

García Barbosa, J.A., Arroyo Osorio, J.M., Córdoba Nieto, E.: Simulation and verification of parametric numerical control programs using a virtual machine tool. Prod. Eng. 8(3), 407–413 (2014). https://doi.org/10.1007/s11740-014-0534-2

Shinde, S.M., Bhole, K.S.: Review of accuracy improvement techniques in high speed 5 axis machining. In: 2015 International Conference on Nascent Technologies in the Engineering Field, ICNTE 2015 - Proceedings (2015). https://doi.org/10.1109/ICNTE.2015.7029906.

Suh, S.H., Seo, Y., Lee, S.M., Choi, T.H., Jeong, G.S., Kim, D.Y.: Modelling and implementation of internet-based virtual machine tools. Int. J. Adv. Manuf. Technol. 21(7), 516–522 (2003). https://doi.org/10.1007/s001700300061

Lagarrigue, P., Maranzana, R., Szalar, T., Brail, A., Reconnet, J., Beceril, R., Cohen, G.: Virtual Reality for NC Machining Improvement. Springer-Verlag, France (2006). https://doi.org/10.1007/978-2-287-48370-7

Hajicek, Z.: Simulation of virtual machine tool during the development phase. In: Annals of DAAAM and Proceedings of the International DAAAM Symposium. pp. 555–560 (2017). https://doi.org/10.2507/28th.daaam.proceedings.078.

Lisboa Borsatti, H., Ramos De Oliveira Santos Arthur, L., Miyashiro Rafael, E., Sugawara Juliana, K., Miyagi Eigi, P., Junqueira, F.: 3D Virtual Environments for Manufacturing Automation. In: ABCM Symposium Series in Mechatronics. pp. 559–567 (2014).

Du, W., Xue, F.: Research on virtual assembly and simulation of CNC grinder. In: Proc. - Int. Conf. Electr. Control Eng. ICECE 2010. (2008), pp. 1811–1814 (2010). https://doi.org/10.1109/iCECE.2010.445.

Meng, F., Zhang, D., Wang, J., Miao, L., Li, P., Hu, H., Li, X.: Design of interactive virtual assembly simulation system for CNC machine tool. In: ACM Int. Conf. Proceeding Ser. 387–391 (2020). https://doi.org/10.1145/3421766.3421889.

Wittstock, V., Kolouch, M., Berthold, J., Richter, M.: Virtual reality based design and calculation tool for improving dynamics of machine tools. MM Sci. J. 2015(OCTOBER), 654–658 (2015). https://doi.org/10.17973/MMSJ.2015_10_201530

Gandhi, P., Deshmukh, S., Ramtekkar, R., Bhole, K., Baraki, A.: “On-Axis” Linear focused spot scanning microstereolithography system: optomechatronic design, analysis and development. J. Adv. Manuf. Syst. 12(1), 43–68 (2013). https://doi.org/10.1142/S0219686713500030

Maier, W., Rothmund, J., Möhring, H.-C., Dang, P.-D., Hoffarth, E., Zinn, B., Wyrwal, M.: Experiencing the structure and features of a machine tool with mixed reality. Procedia CIRP. 106, 244–249 (2022). https://doi.org/10.1016/j.procir.2022.02.186

da Silva, A.G., Gomes, M.V.M., Winkler, I.: Virtual reality and digital human modeling for ergonomic assessment in industrial product development: a patent and literature review. Appl. Sci. (2022). https://doi.org/10.3390/app12031084

Siemens Product Lifecycle Management Software.

Shinde, S.M., Lekurwale, R.R.: Parametric mathematical modelling and aspect ratio optimization of eccentric spiral profile flexural bearing through finite element analysis studies. SSRN Electron. J. (2018). https://doi.org/10.2139/ssrn.3101366

Bhole, K.S., Janbandhu, M.: Design and Development of Double Spiral Shaped Flexural Feed Stage for Micro-drilling Workstation. In: International Conference on Advances in Materials and Manufacturing Applications [IConAMMA 2017]. pp. 25468–25476. Elsevier Ltd (2018). https://doi.org/10.1016/j.matpr.2018.10.352.

Bhole, K., Sonavane, V.: Parameter based method for three arm spiral shaped flexural bearing. In: Materials Today: Proceedings. pp. 19380–19390. Elsevier Ltd (2018). https://doi.org/10.1016/j.matpr.2018.06.298.

Sonavane, V., Bhole, K.: Static and Frequency Analysis of Triple Stage Three Arm Spiral Shape Flexural bearing using FEA. In: Materials Today: Proceedings. pp. 1383–1391. Elsevier Ltd. (2020). https://doi.org/10.1016/j.matpr.2020.04.456.

Bhole, K., Mastud, S.: Generalized design methodology for three-arm spiral cut compliant linear stage. In: Sachdeva, A., Kumar, P., Yadav, O.P., Garg, R.K., Gupta, A. (eds.) Operation Management and Systems Engineering, pp. 127–144. Springer Nature Singapore Pte Ltd, Singapore (2019). https://doi.org/10.1007/978-981-15-6017-0_8

Bohez, E.L.J.: Five-axis milling machine tool kinematic chain design and analysis. Int. J. Mach. Tools Manuf. 42(4), 505–520 (2002). https://doi.org/10.1016/S0890-6955(01)00134-1

Lin, G.: System and Method for Constructing Virtual NC Controllers for Machine Tool Simulation, (2013).

Guzeev, V.I., Pimenov, D.Y.: Methodology of designing integrated technological processes for manufacturing CNC machined parts. In: MATEC Web Conferences, p 224 (2018). https://doi.org/10.1051/matecconf/201822401057.

Fanuc, G.: GE Fanuc Automation, North America (1998).

Suh, S.-H., Kang, S.-K., Chung, D.-H., Stroud, I.: Theory and Design of CNC Systems -. Springer, London (2008)

Raju, R., Manikandan, N., Palanisamy, D., Arulkirubakaran, D., Binoj, J.S., Thejasree, P., Ahilan, C.: A Review of Challenges and Opportunities in Additive Manufacturing. In: Palani, I.A., Sathiya, P., Palanisamy, D. (eds.) Recent Advances in Materials and Modern Manufacturing Lecture Notes in Mechanical Engineering. Springer, Singapore (2022). https://doi.org/10.1007/978-981-19-0244-4_3

Varma, M.M.M.K., Baghel, P.K., Raju, R.: Additive manufacturing of thermosetting resins in-situ carbon fibers: a review. In: Palani, I.A., Sathiya, P., Palanisamy, D. (eds.) Recent Advances in Materials and Modern Manufacturing. Lecture Notes in Mechanical Engineering. Springer, Singapore (2022). https://doi.org/10.1007/978-981-19-0244-4_11

Thirugnanasambantham, K.G., Francis, A., Ramesh, R., Aravind, M., Reddy, M.K.: Investigation of erosion mechanisms on IN-718 based turbine blades under water jet conditions. Int. J. Interact. Des. Manuf. (2022). https://doi.org/10.1007/s12008-022-00910-4

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the author(s).

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shinde, S.M., Lekurwale, R.R., Bhole, K.S. et al. 5-axis virtual machine tool centre building in PLM environment. Int J Interact Des Manuf (2022). https://doi.org/10.1007/s12008-022-00974-2

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-022-00974-2