Abstract

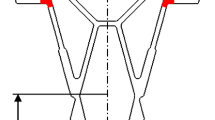

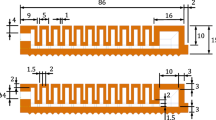

This paper is aimed to provide a new design modeling of the gripper via using the intelligent computing model. The gripper is designed to get benefit of a symmetric structure and compliant mechanism that can manipulate the objects with a stable force. The numerically experimental samples for the gripper are built and the finite element simulations are implemented. The displacement of left hand is collected. An intelligent computing model is formulated via a hybridization of the teaching learning optimization and feed forward neural network. The teaching learning optimization algorithm is embedded into neural network to enhance the training process. The results determined that the mean square error values of the entire model, the training, the testing, and validating are about 6.04e-07, 6.11e-07, 6.50e-08, and 1.10e-06, respectively. Furthermore, the coefficient of determination value of the entire model, the training, the testing, and validating are 0.9975, 0.9970, 0.9998, and 0.9677, accordingly. In addition, the proposed intelligent predictor is outperformed other regression methods such as linear regression, full 2nd order polynomial regression, and traditional artificial neural network. Moreover, the errors among the estimated from the proposed intelligent method and the prediction errors are less than 3%. It revealed that the proposed intelligent methodology is a well-suitable predictor for modeling the behaviors of gripper. The gripper is capable of providing a displacement amplification ratio of 2.85 and a max grasping force of 145.96 N. The gripper is potential for many practical applications such as robotics and manipulators in agricultural and electrics engineering.

Similar content being viewed by others

References

Nguyen, P., Ho, V.A.: Grasping interface with wet adhesion and patterned morphology: case of thin shell. IEEE Robot. Autom. Lett. 4, 792–799 (2019). https://doi.org/10.1109/LRA.2019.2893401

Nguyen Van, P., Bui, T.H., Ho, V.A.: (2021) Towards safely grasping group objects by hybrid robot hand. 2021 4th Int Conf Robot Control Autom Eng RCAE 2021 1:389–393. https://doi.org/10.1109/RCAE53607.2021.9638841

Dong, H., Asadi, E., Qiu, C., et al.: Geometric design optimization of an under-actuated tendon-driven robotic gripper. Robot. Comput. Integr. Manuf. 50, 80–89 (2018). https://doi.org/10.1016/j.rcim.2017.09.012

Blanes, C., Ortiz, C., Mellado, M., Beltrán, P.: Assessment of eggplant firmness with accelerometers on a pneumatic robot gripper. Comput Electron. Agric. 113, 44–50 (2015). https://doi.org/10.1016/j.compag.2015.01.013

Xiong, Y., Peng, C., Grimstad, L., et al.: Development and field evaluation of a strawberry harvesting robot with a cable-driven gripper. Comput. Electron. Agric 157, 392–402 (2019). https://doi.org/10.1016/j.compag.2019.01.009

Nishida, T., Okatani, Y., Tadakuma, K.: Development of universal robot gripper using MR α Fluid. Int. J. Humanoid Robot 13, 1–13 (2016). https://doi.org/10.1142/S0219843616500171

Sandhu, K., Singh, G., Singh, S., et al.: Surface characteristics of machined polystyrene with 3D printed thermoplastic tool. Materials (Basel) 13, 1–16 (2020). https://doi.org/10.3390/ma13122729

Miao, Y., Zheng, J.: Optimization design of compliant constant-force mechanism for apple picking actuator. Comput. Electron. Agric. 170, 105232 (2020). https://doi.org/10.1016/j.compag.2020.105232

Dao, T.: Robust parameter design for a compliant microgripper based on hybrid Taguchi-differential evolution algorithm. Microsyst. Technol. (2017). https://doi.org/10.1007/s00542-017-3534-2

Le Chau, N., Ho, N.L., Tran, N.T., Dao, T.-P.: Analytical model and computing optimization of a compliant gripper for the assembly system of mini direct-current motor. Int. J. Ambient Comput. Intell. (2021). https://doi.org/10.4018/ijaci.2021010101

Le Chau, N., Ho, N.L., Vinh Chung, T.T., et al.: Computing optimization of a parallel structure-based monolithic gripper for manipulation using weight method-based grey relational analysis. Int. J. Ambient Comput. Intell. 12, 39–74 (2021). https://doi.org/10.4018/IJACI.2021070103

Deshwal, S., Kumar, A., Chhabra, D.: Exercising hybrid statistical tools GA-RSM, GA-ANN and GA-ANFIS to optimize FDM process parameters for tensile strength improvement. CIRP J. Manuf. Sci. Technol. 31, 189–199 (2020). https://doi.org/10.1016/j.cirpj.2020.05.009

Pant, P., Chatterjee, D.: Prediction of clad characteristics using ANN and combined PSO-ANN algorithms in laser metal deposition process. Surf. Interfaces 21, 100699 (2020). https://doi.org/10.1016/j.surfin.2020.100699

Prakash, C., Singh, S., Singh, M., et al.: Multi-objective parametric appraisal of pulsed current gas tungsten arc welding process by using hybrid optimization algorithms. Int. J. Adv. Manuf. Technol. 101, 1107–1123 (2019). https://doi.org/10.1007/s00170-018-3017-3

Rao, R.V., Singh, H.: Rao algorithms for multi - objective optimization of selected thermodynamic cycles. Eng. Comput. (2020). https://doi.org/10.1007/s00366-020-01008-9

Ling, M., Howell, L.L., Cao, J., Chen, G.: Kinetostatic and dynamic modeling of flexure-based compliant mechanisms: a survey. Appl. Mech. Rev. (2020). https://doi.org/10.1115/1.4045679

Hassan, A., Abomoharam, M.: Modeling and design optimization of a robot gripper mechanism. Robot Comput. Integr. Manuf. 46, 94–103 (2017). https://doi.org/10.1016/j.rcim.2016.12.012

Haibin, Y., Cheng, K., Junfeng, L., Guilin, Y.: Modeling of grasping force for a soft robotic gripper with variable stiffness. Mech. Mach. Theory 128, 254–274 (2018). https://doi.org/10.1016/j.mechmachtheory.2018.05.005

Jain, R.K., Majumder, S., Ghosh, B., Saha, S.: Design and manufacturing of mobile micro manipulation system with a compliant piezoelectric actuator based micro gripper. J. Manuf. Syst. 35, 76–91 (2015). https://doi.org/10.1016/j.jmsy.2014.12.001

Zhang, X., Xu, Q.: Design and testing of a novel 2-DOF compound constant-force parallel gripper. Precis Eng. (2019). https://doi.org/10.1016/j.precisioneng.2018.09.004

Wandra, R., Prakash, C., Singh, S.: Experimental investigation and optimization of surface roughness of β-Phase titanium alloy by ball burnishing assisted electrical discharge cladding for implant applications. Mater. Today Proc 48, 975–980 (2021). https://doi.org/10.1016/j.matpr.2021.06.070

Sharma, A., Kumar, V., Babbar, A., et al.: Experimental investigation and optimization of electric discharge machining process parameters using grey-fuzzy-based hybrid techniques. Materials (Basel) (2021). https://doi.org/10.3390/ma14195820

Babbar, A., Prakash, C., Singh, S., et al.: Application of hybrid nature-inspired algorithm: single and bi-objective constrained optimization of magnetic abrasive finishing process parameters. J. Mater. Res. Technol. 9, 7961–7974 (2020). https://doi.org/10.1016/j.jmrt.2020.05.003

Pramanik, A., Islam, M.N., Basak, A.K., et al.: Optimizing dimensional accuracy of titanium alloy features produced by wire electrical discharge machining. Mater. Manuf. Process 34, 1083–1090 (2019). https://doi.org/10.1080/10426914.2019.1628259

Ling, M., Song, D., Zhang, X., et al.: Analysis and design of spatial compliant mechanisms using a 3-D dynamic stiffness model. Mech. Mach. Theory 168, 104581 (2022). https://doi.org/10.1016/j.mechmachtheory.2021.104581

Konak, A., Coit, D.W., Smith, A.E.: Multi-objective optimization using genetic algorithms: a tutorial. Reliab Eng Syst Saf 91, 992–1007 (2006). https://doi.org/10.1016/j.ress.2005.11.018

Antil, P., Kumar Antil, S., Prakash, C., et al.: Multi-objective optimization of drilling parameters for orthopaedic implants. Meas Control (United Kingdom) 53, 1902–1910 (2020). https://doi.org/10.1177/0020294020947126

Nilanjan, D., Ashour, A.S., Bhattacharyya, S.: Applied nature-inspired computing: algorithms and case studies. Springer Singapore (2020). https://link.springer.com/book/10.1007/978-981-13-9263-4?noAccess=true

Jagatheesan, K., Anand, B., Samanta, S., et al.: Application of flower pollination algorithm in load frequency control of multi-area interconnected power system with nonlinearity. Neural Comput. Appl. 28, 475–488 (2017). https://doi.org/10.1007/s00521-016-2361-1

Binh, H.T.T., Hanh, N.T., Van Quan, L., Dey, N.: Improved cuckoo search and chaotic flower pollination optimization algorithm for maximizing area coverage in wireless sensor networks. Neural Comput. Appl. 30, 2305–2317 (2018). https://doi.org/10.1007/s00521-016-2823-5

Cao, J., Cui, H., Shi, H., Jiao, L.: Big data: a parallel particle swarm optimization-back-propagation neural network algorithm based on MapReduce. PLoS ONE 11, 1–17 (2016). https://doi.org/10.1371/journal.pone.0157551

Chatterjee, S., Sarkar, S., Hore, S., et al.: Particle swarm optimization trained neural network for structural failure prediction of multistoried RC buildings. Neural Comput. Appl. 28, 2005–2016 (2017). https://doi.org/10.1007/s00521-016-2190-2

Seifi, A., Soroush, F.: Pan evaporation estimation and derivation of explicit optimized equations by novel hybrid meta-heuristic ANN based methods in different climates of Iran. Comput. Electron. Agric. (2020). https://doi.org/10.1016/j.compag.2020.105418

Hore, S., Chatterjee, S., Santhi, V., et al.: Optimized Neural Networks. 139–151 (2017) https://doi.org/10.1007/978-3-319-38771-0

Cappelli, L., Balokas, G., Montemurro, M., et al.: Multi-scale identification of the elastic properties variability for composite materials through a hybrid optimisation strategy. Compos. Part B Eng. (2019). https://doi.org/10.1016/j.compositesb.2019.107193

Rao, R.V., Savsani, V.J., Vakharia, D.P.: Teaching-learning-based optimization: an optimization method for continuous non-linear large scale problems. Inf. Sci. (Ny) 183, 1–15 (2012). https://doi.org/10.1016/j.ins.2011.08.006

Acknowledgements

This research is supported by Industrial University of Ho Chi Minh City (IUH) under grant number 01/HD-DHCN.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nguyen, D.N., Dang, M.P., Nguyen, T.T. et al. Intelligent computation modeling and analysis of a gripper for advanced manufacturing application. Int J Interact Des Manuf 17, 2185–2195 (2023). https://doi.org/10.1007/s12008-022-00885-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-022-00885-2