Abstract

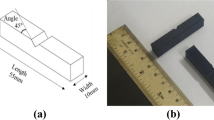

In this study, significant process parameters (layer thickness, build orientation, infill density and number of contours) are optimized for enhancing the magnitude/dimensional preciseness of fused deposition modeling (FDM) devise units. Hybrid statistical tools such as response surface methodology–genetic algorithm (RSM–GA), artificial neural network (ANN) and artificial neural network-genetic algorithm (ANN-GA) in MAT LAB 16.0 are utilized for training and optimization. An attempt has been made to build up a mathematical model in order to set up an indirect correlation between various FDM process parameters and magnitude preciseness. Sequentially to verify the different developed models and the optimum process parameters setting validation tests were also performed. The results showed that various hybrid statistical tools such as RSM-GA, ANN and ANN-GA are very adequate tools for FDM process parameter optimization. The minimum percentage variation in length = 0.06409%, width = 0.03961% and thickness = 0.85689% can be obtained by using ANN-GA.

Similar content being viewed by others

References

Yan, X., Gu, P.: A review of rapid prototyping technologies and systems. Comput. Aided Des. 4, 307–316 (1996)

Lee, B.H., Abdullah, J., Khan, Z.A.: Optimization of rapid prototyping parameters for production of flexible ABS object. J. Mater. Process. Technol. 169, 54–61 (2005)

Mohamed, O.A., Masood, S.H., Bhowmik, J.L.: Experimental investigation of time dependent mechanical properties of PC-ABS prototypes processed by FDM additive manufacturing process. Mater. Lett. 193, 58–62 (2017)

Khodaygan, S., Golmohammadi, A.H.: Multi-criteria optimization of the part build orientation (PBO) through a combinedmeta-modeling/NSGAII/TOPSISmethod for additive manufacturing processes. Int. J. Interact. Des. Manuf. 12, 1071–1085 (2017)

Rayegani, F., Onwubolu, G.: Fused deposition modelling (FDM) process parameter prediction and optimization using group method for data handling (GMDH) and differential evolution (DE). Int. J. Adv. Manuf. Technol. 73, 509–519 (2014)

Nidagundi, V.B., Keshavamurthy, R., Prakash, C.P.S.: Studies on parametric optimization for fused deposition modelling. Process. Materi. Today Proc. 2, 1691–1699 (2015)

Alafaghani, A., Qattawi A., Alrawi B., Guzman, A.: Experimental optimization of fused deposition modelling processing parameters: a design-for-manufacturing approach. In: North American Manufacturing Research Conference, LA, USA, vol. 10, pp. 791–803 (2017)

Mohamed, O.A., Masood, S.H., Bhowmik, J.L.: Mathematical modeling and FDM process parameters optimization using response surface methodology based on Q-optimal design. Appl. Math. Model. 40, 10052–10073 (2016)

Sood, A.K., Ohdar, R.K., Mahapatra, S.S.: Improving magnitude preciseness of fused deposition modelling processed part using grey Taguchi method. Mater. Des. 30, 4243–4252 (2009)

Lieneke, T., Denzer, V., Adam, G.A.O., Zimmer, D.: Magnitude tolerances for additive manufacturing: experimental investigation for fused deposition modeling. Procedia CIRP 43, 286–291 (2016)

Sahu, R.K., Mahapatra, S.S., Sood, A.K.: A study on magnitude preciseness of fused deposition modeling (FDM) processed parts using fuzzy logic. J. Manuf. Sci. Prod. 13(3), 183–197 (2013)

Equbal, A., Sood, A.K., Ohdar, R.K., Mahapatra, S.S.: Prediction of magnitude preciseness in fused deposition modelling: a fuzzy logic approach. Int. J. Product. Qual. Manag. 7, 22–43 (2011)

Chou, K., Zhang, Y.: A parametric study of part distortion in fused deposition modeling using three magnitude element analysis. J. Eng. Manuf. 222(B), 959–967 (2008)

Mohamed, O.A., Masood, S.H., Bhowmik, J.L.: Optimization of fused deposition modeling process parameters: a review of current research and future prospects. Adv. Manuf. 3, 42–53 (2015)

Wang, C.C., Lin, T., Hu, S.: Optimizing the rapid prototyping process by integrating the Taguchi method with the Gray relational analysis. Rapid Prototyp. J. 13, 304–315 (2007)

Kim, G.D., Oh, Y.T.: A benchmark study on rapid prototyping processes and machines: quantitative comparisons of mechanical properties, accuracy, roughness, speed, and material cost. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2, 201–215 (2008)

Ordaz-Hernandez, K., Fischer, X., Bennis, F.: Granular modeling for virtual prototyping in interactive design. Virtual Phys. Prototyp. 2(2), 111–126 (2007)

Nadeau, J.P., Fischer, X.: Research in interactive design: virtual, interactive and integrated product design and manufacturing for industrial innovation. Springer, Berlin (2011)

Davorin, Kramar, Djordje, Cica, Branislav, Sredanovic, Janez, Kopa: Design of fuzzy expert system for predicting of surface roughness in high-pressure jet assisted turning using bioinspired algorithms. Artif. Intell. Eng. Des. Anal. Manuf. 30, 96–106 (2016)

Singh, P.K., Jain, S.C., Jain, P.K.: Comparative study of genetic algorithm and simulated annealing for optimal tolerance design formulated with discrete and continuous variables. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 10, 735–758 (2005)

Singh, P.K., Jain, S.C., Jain, P.K.: A genetic algorithm based solution to optimum tolerance synthesis of mechanical assemblies with alternate manufacturing processes—benchmarking with the exhaustive search method using the Lagrange multiplier. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 7, 765–778 (2004)

Rojek, I.: Technological process planning by the use of neural networks. Artif. Intell. Eng. Des. Anal. Manuf. 31, 1–15 (2017)

Christiyan, K.G.J., Chandrasekhar, U., Venkateswarlu, K.: A study on the influence of process parameters on the mechanical properties of 3D printed ABS composite. IOP Conf. Ser. Mater. Sci. Eng. 114, 012109 (2016). https://doi.org/10.1088/1757-899X/114/1/012109

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Deswal, S., Narang, R. & Chhabra, D. Modeling and parametric optimization of FDM 3D printing process using hybrid techniques for enhancing dimensional preciseness. Int J Interact Des Manuf 13, 1197–1214 (2019). https://doi.org/10.1007/s12008-019-00536-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-019-00536-z