Abstract

In this study, active–passive anticorrosion antistatic epoxy composite coatings containing CeO2, carbon coated ceria (CeO2@C), and carbon hollow sphere particles were prepared. Cerium oxide (CeO2) particles were synthesized through a hydrothermal approach in the presence of polyvinylpyrrolidone as a surfactant to achieve a uniform and semispherical morphology and to improve dispersion stability. Carbon hollow spheres (CHSs) were also fabricated using the surface-modified silica templating method. The structure and morphology of the synthesized particles were analyzed using Fourier transform infrared spectrometry, X-ray diffractometry, Raman spectrometry, and scanning electron microscopy–energy-dispersive X-ray spectroscopy (SEM-EDS). Furthermore, migration of the synthesized particles from the bulk toward the surface was investigated with atomic force microscopy, Raman spectra, and field emission SEM in addition to density, capillary wetting, contact angle, and zeta potential measurements. The results indicated that CHSs migrate toward the surface of the matrix due to its low interfacial tensions leading to a decline in the dielectric constant and electrical resistance, providing a composite with suitable antistatic properties. Moreover, electrochemical impedance spectroscopy and immersion testing were used to estimate the influence of the particles on the coating's anticorrosive property. The results showed that the impedance modulus at low frequency (|Z|0.01 Hz) significantly increased from 3.81 × 106 Ω cm2 (pristine epoxy) to 11 × 108 Ω cm2 after 40 days of immersion in 3.5% NaCl water solution. As a result of the synergistic protection provided by ceria, CHS, and CeO2@C particles, composite coatings exhibit superior anticorrosion properties. The ceria particles have an inhibitory effect which forms a passive layer. Furthermore, the CHS and CeO2@C particles produce a protective barrier prolonging the penetration pathway of corrosive media. Such significant improvements can provide an antistatic coating for designing novel corrosion protection coatings.

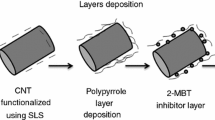

Graphical abstract

Similar content being viewed by others

References

Liu, X, et al. “Research on the Preparation and Anticorrosion Properties of EP/CeO2-GO Nanocomposite Coating.” Polymers, 13 (2) 183 (2021)

Verma, C, et al. “Epoxy Resins as Anticorrosive Polymeric Materials: A Review.” React. Funct. Polym., 156 104741 (2020)

Hsissou, R, “Review on Epoxy Polymers and Its Composites as a Potential Anticorrosive Coatings for Carbon Steel in 3.5% NaCl Solution: Computational Approaches.” J. Mol. Liq., 336 116307 (2021)

Paluvai, NR, Mohanty, S, Nayak, S, “Synthesis and Modifications of Epoxy Resins and Their Composites: A Review.” Polym. Plast. Technol. Eng., 53 (16) 1723–1758 (2014)

Liu, S, et al. “A Review of Extending Performance of Epoxy Resins Using Carbon Nanomaterials.” Compos. Part B Eng., 136 197–214 (2018)

Kausar, A, “Performance of Corrosion Protective Epoxy Blend-Based Nanocomposite Coatings: A Review.” Polym. Plast. Technol. Mater., 59 (6) 658–673 (2020)

Ahmadi, Z, “Epoxy in Nanotechnology: A Short Review.” Prog. Org. Coat., 132 445–448 (2019)

Yousefi Limaee N, et al. “Evaluation of Adsorptive Efficiency of Calcium Oxide Nanoparticles for the Elimination of Cationic Dyes: Combustion Synthesis, Adsorption Study and Numerical Modeling.” Prog. Color Color. Coat., (2022)

Tikhani, F, et al. “Cure Index Demonstrates Curing of Epoxy Composites Containing Silica Nanoparticles of Variable Morphology and Porosity.” Prog. Org. Coat., 135 176–184 (2019)

Chen, Y, et al. “Preparation of α-Fe2O3@ TA@ GO Composite Material and Its Anticorrosion Performance in Epoxy Modified Acrylic Resin Coatings.” Prog. Org. Coat., 154 105987 (2021)

Wan, P, et al. “Synthesis of PDA-BN@f-Al2O3 Hybrid for Nanocomposite Epoxy Coating with Superior Corrosion Protective Properties.” Prog. Org. Coat., 146 105713 (2020)

Aboorvakani, R, Vethanathan, SJK, Madhu, K, “Influence of Zn Concentration on Zinc Oxide Nanoparticles and Their Anti-Corrosion Property.” J. Alloys Compd., 834 155078 (2020)

Li, W, Tian, H, Hou, B, “Corrosion Performance of Epoxy Coatings Modified by Nanoparticulate SiO2.” Mater. Corros., 63 (1) 44–53 (2012)

Fadl, A, et al. “Corrosion-Inhibiting, Self-healing, Mechanical-Resistant, Chemically and UV Stable PDMAS/TiO2 Epoxy Hybrid Nanocomposite Coating for Steel Petroleum Tanker Trucks.” Prog. Org. Coat., 146 105715 (2020)

Chen, Z, et al. “Smart Coatings Embedded with Polydopamine-Decorated Layer-by-Layer Assembled SnO2 Nanocontainers for the Corrosion Protection of 304 Stainless Steels.” J. Colloid Interface Sci., 579 741–753 (2020)

Chang, J, et al. “Corrosion Resistance of Tannic Acid, d-Limonene and Nano-ZrO2 Modified Epoxy Coatings in Acid Corrosion Environments.” J. Mater. Sci. Technol., 65 137–150 (2021)

Eskandari, M, et al. “Effect of Nano-Metal Oxides (ZnO, Al2O3, CuO, and TiO2) on the Corrosion Behavior of a Nano-Metal Oxide/Epoxy Coating Applied on the Copper Substrate in the Acidic Environment.” Appl. Nanosci., 11 (5) 1605–1615 (2021)

Ackland, K, Coey, J, “Room Temperature Magnetism in CeO2—A Review.” Phys. Rep., 746 1–39 (2018)

Merrifield, RC, et al. “Synthesis and Characterization of Polyvinylpyrrolidone Coated Cerium Oxide Nanoparticles.” Environ. Sci. Technol., 47 (21) 12426–12433 (2013)

Patil, P, et al. “Au Sensitized La–CeO2 Catalyst Coated Ceramics Monoliths for Toluene Catalysis Application.” Mater. Chem. Phys., 240 122269 (2020)

Zhang, H, et al. “Controllable Synthesis of Spherical Cerium Oxide Particles.” RSC Adv., 6 (37) 30956–30962 (2016)

Mahmoud, WE, Faidah, A, “Microwave Assisted Hydrothermal Synthesis of Engineered Cerium Oxide Nanopowders.” J. Eur. Ceram. Soc., 32 (13) 3537–3541 (2012)

Hao, C-C, et al. “Facile Solvothermal Synthesis of a Z-Scheme 0D/3D CeO2/ZnIn2S4 Heterojunction with Enhanced Photocatalytic Performance under Visible Light Irradiation.” Chem. Eng. J., 409 128168 (2021)

Lu, Y, et al. “Flame Spray Pyrolysis Synthesized CuO–CeO2 Composite for Catalytic Combustion of C3H6.” Proc. Combust. Inst., 38 (4) 6513–6520 (2021)

Yulizar, Y, et al. “Novel Sol–Gel Synthesis of CeO2 Nanoparticles Using Morinda citrifolia L. Fruit Extracts: Structural and Optical Analysis.” J. Mol. Struct., 1231 129904 (2021)

Zheng, J, et al. “Mechanism of CeO2 Synthesized by Thermal Decomposition of Ce-MOF and Its Performance of Benzene Catalytic Combustion.” J. Rare Earths, 39 (7) 790–796 (2021)

Gu, S, et al. “Mesoporous CeO2 Containers in Water-Borne Epoxy Coatings for Dual Active Corrosion Protection of Mild Steel.” Prog. Org. Coat., 158 106376 (2021)

An, K, et al. “Synergistic Reinforcement Coating with Anti-corrosion and UV Aging Resistance by Filling Modified CeO2 Nanoflakes.” Colloids Surf. A Physicochem. Eng. Asp., 625 126904 (2021)

Zhang, W, et al. “Effects of CeO2 Geometry on Corrosion Resistance of Epoxy Coatings.” Surf. Eng., 36 (2) 175–183 (2020)

Chaubey, N, et al. “Frontiers and Advances in Green and Sustainable Inhibitors for Corrosion Applications: A Critical Review.” J. Mol. Liq., 321 114385 (2021)

Abdullayev, E, Lvov, Y, “Clay Nanotubes for Corrosion Inhibitor Encapsulation: Release Control with End Stoppers.” J. Mater. Chem., 20 (32) 6681–6687 (2010)

Javidparvar, AA, et al. “Graphene Oxide as a pH-Sensitive Carrier for Targeted Delivery of Eco-Friendly Corrosion Inhibitors in Chloride Solution: Experimental and Theoretical Investigations.” J. Ind. Eng. Chem., 72 196–213 (2019)

Shahini, M, et al. “A Comprehensive Overview of Nano and Micro Carriers Aiming at Curtailing Corrosion Progression.” J. Taiwan Inst. Chem. Eng., 126 252–269 (2021)

Haddadi, SA, et al. “Synthesis and Application of Mesoporous Carbon Nanospheres Containing Walnut Extract for Fabrication of Active Protective Epoxy Coatings.” Prog. Org. Coat., 133 206–219 (2019)

Khan, A, et al. “Hybrid Halloysite Nanotubes as Smart Carriers for Corrosion Protection.” ACS Appl. Mater. Interfaces, 12 (33) 37571–37584 (2020)

Sun, D, et al. “Effect of Zeta Potential and Particle Size on the Stability of SiO2 Nanospheres as Carrier for Ultrasound Imaging Contrast Agents.” Int. J. Electrochem. Sci, 11 (10) 8520–8529 (2016)

Liu, D, Bi, Y-G, “Controllable Fabrication of Hollow TiO2 Spheres as Sustained Release Drug Carrier.” Adv. Powder Technol., 30 (10) 2169–2177 (2019)

Habib, S, Shakoor, R, Kahraman, R, “A Focused Review on Smart Carriers Tailored for Corrosion Protection: Developments, Applications, and Challenges.” Prog. Org. Coat., 154 106218 (2021)

Liu, C, et al. “Stimulus Responsive Zeolitic Imidazolate Framework to Achieve Corrosion Sensing and Active Protecting in Polymeric Coatings.” ACS Appl. Mater. Interfaces, 13 (3) 4429–4441 (2021)

Wen, J, et al. “An Intelligent Coating Based on pH-Sensitive Hybrid Hydrogel for Corrosion Protection of Mild Steel.” Chem. Eng. J., 392 123742 (2020)

Feng, X, et al. “Fabrication and Characterization of Antistatic Epoxy Composite with Multi-walled Carbon Nanotube-Functionalized Melamine Foam.” RSC Adv., 8 (27) 14740–14746 (2018)

Chen, Z-H, et al. “Preparation of Light Color Antistatic and Anticorrosive Waterborne Epoxy Coating for Oil Tanks.” J. Coat. Technol. Res., 5 (2) 259–269 (2008)

Haddadi, S, et al. “Self-Healing Epoxy Nanocomposite Coatings Based on Dual-Encapsulation of Nano-Carbon Hollow Spheres with Film-Forming Resin and Curing Agent.” Compos. Part B Eng., 175 107087 (2019)

Rostami, M, Mohseni, M, Ranjbar, Z, “Investigating the Effect of pH on the Surface Chemistry of an Amino Silane Treated Nano Silica.” Pigment Resin Technol., 40 (6) 363–373 (2011)

Eom, H, et al. “Evaluating the Electrochemical Properties of Supercapacitors Using the Three-Electrode System.” JoVE J. Vis. Exp., 179 e63319 (2022)

Alghunaim, A, Newby, B-MZ, “Influence of Tube Wettability on Water Contact Angle of Powders Determined by Capillary Rise.” Colloids Surf. A, Physicochem. Eng. Asp., 492 79–87 (2016)

Liu, Z, Yu, X, Wan, L, “Capillary Rise Method for the Measurement of the Contact Angle of Soils.” Acta Geotech., 11 21–35 (2016)

Kirdponpattara, S, Phisalaphong, M, Newby, B-MZ, “Applicability of Washburn Capillary Rise for Determining Contact Angles of Powders/Porous Materials.” J. Colloid Interface Sci., 397 169–176 (2013)

Mendez, JAC, Vong, YM, Bueno, JDJP, “Cerium and Other Rare Earth Salts as Corrosion Inhibitors—A Review.” Prot. Metals Phys. Chem. Surf., 58 (4) 801–810 (2022)

Voevodin, N, et al. “Potentiodynamic Evaluation of Sol–Gel Coatings with Inorganic Inhibitors.” Surf. Coat. Technol., 140 (1) 24–28 (2001)

Iravani, D, et al. “Experimental and Computational Study of Aromatic Ring Effects on Corrosion Inhibition in the H2S Media.” Mater. Today Commun., 35 105559 (2023)

Trinstancho-Reyes, J, et al. “Electrochemical Impedance Spectroscopy Investigation of Alloy Inconel 718 in Molten Salts at High Temperature.” Int. J. Electrochem. Sci., 6 (2) 419–431 (2011)

Deyab, M, “Effect of Carbon Nano-Tubes on the Corrosion Resistance of Alkyd Coating Immersed in Sodium Chloride Solution.” Prog. Org. Coat., 85 146–150 (2015)

Hammer, P, et al. “Carbon Nanotube-Reinforced Siloxane-PMMA Hybrid Coatings with High Corrosion Resistance.” Prog. Org. Coat., 76 (4) 601–608 (2013)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sabzavar, S., Ghahari, M., Rostami, M. et al. Preparation of active–passive anticorrosion antistatic epoxy nanocomposite coatings loaded with CeO2, CeO2@C, and CHS particles. J Coat Technol Res (2024). https://doi.org/10.1007/s11998-023-00890-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11998-023-00890-4