Abstract

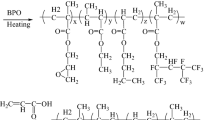

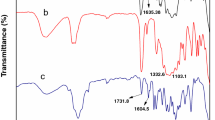

Introducing nanofillers into UV-curable coatings can not only effectively improve the performance of the coating but also impart new functions to the film. Herein, methacrylate-functionalized aramid nanofibers (mANFs) were constructed by a bottom-up approach, and their influence on the performance of UV-curable epoxy acrylate (EA) coatings was investigated. The microstructure of the EA/mANF nanocomposite was studied using X-ray diffraction and transmission electron microscopy (TEM), which confirmed the homogeneous distribution of mANFs in the matrix. The effect of mANFs on the curing kinetics was investigated. The result showed that the photopolymerization rate and final C = C bond conversion would not be adversely affected until more than 0.1 wt% mANFs were added. The UV–Vis analyses showed that the EA/mANF films maintained high transmittance in the visible light region and exhibited improved UV-shielding performance. The mechanical characteristics of EA/mANF films were significantly improved by mANFs because of strong interactions such as π–π interactions, hydrogen bonds, and chemical bonds between the matrix and mANFs. For the nanocomposite containing 0.025 wt% mANFs, tensile strength and strain at break increased by 53% and 446%, respectively, compared to neat EA. Thus, the introduction of mANFs considerably improved the mechanical performance of UV-curable EA films and expanded their application in the field of UV shielding.

Similar content being viewed by others

References

Işın, D, Kayaman-Apohan, N, Güngör, A, “Preparation and Characterization of UV-Curable Epoxy/Silica Nanocomposite Coatings.” Prog. Org. Coat., 65 (4) 477–483 (2009)

Zhang, S, Guo, M, Chen, Z, Liu, QH, et al. “Grafting Photosensitive Polyurethane Onto Colloidal Silica for Use in UV-Curing Polyurethane Nanocomposites.” Colloid Surf. A, 443 525–534 (2014)

Zhang, S, Chen, Z, Guo, M, et al. “Waterborne UV-Curable Polycarbonate Polyurethane Nanocomposites Based on Polydimethylsiloxane and Colloidal Silica with Enhanced Mechanical and Surface Properties.” RSC Adv., 4 (58) 30938–30947 (2014)

Jeong, KM, Park, SS, Nagappan, S, et al. “Highly Transparent, Organic-Inorganic Hybrid UV-Curable Coating Materials with Amphiphobic Characteristics.” Prog. Org. Coat., 134 323–332 (2019)

Park, S, Kim, J, Han, TW, et al. “Mechanical Reinforcement of UV-Curable Polymer Nanocomposite for Nanopatterned Mold.” Microelectron. Eng., 259 111791 (2022)

Cui, Y, Chen, Z, Liu, X, “Preparation of UV-Curing Polymer-ZrO2 Hybrid Nanocomposites via Auto-Hydrolysis Sol-Gel Process Using Zirconium Oxychloride Octahydrate Coordinated with Organic Amine.” Prog. Org. Coat., 100 178–187 (2016)

Macarie, L, Plesu, N, Iliescu, S, et al. “UV-Curable Nanocomposites Containing Zirconium Vinylphosphonate or Zirconia.” J. Appl. Polym. Sci., 119 (3) 1820–1826 (2010)

Pavlacky, E, Webster, DC, “An In Situ Intercalative Polymerization Method for Preparing UV Curable Clay-Polymer Nanocomposites.” J. Appl. Polym. Sci., 132 42601 (2015)

Lv, S, Wei, Z, Song, L, et al. “A Novel Method for Preparation of Exfoliated UV-Curable Polymer/Clay Nanocomposites.” Eur. Polym. J., 44 (6) 1613–1619 (2008)

Jeong, YG, An, JE, “UV-Cured Epoxy/Graphene Nanocomposite Films: Preparation, Structures and Electric Heating Performance.” Polym. Int., 63 (11) 1895–1901 (2014)

Martin-Gallego, M, Verdejo, R, Lopez-Manchado, MA, et al. “Epoxy-Graphene UV-Cured Nanocomposites.” Polymer., 52 (21) 4664–4669 (2011)

Yu, B, Shi, Y, Yuan, B, et al. “Click-Chemistry Approach for Graphene Modification: Effective Reinforcement of UV-Curable Functionalized Graphene/Polyurethane Acrylate Nanocomposites.” RSC Adv., 5 (18) 13502–13506 (2015)

Li, YW, Zhong, J, Wu, LX, et al. “High Performance POSS Filled Nanocomposites Prepared via UV-Curing Based on 3D Stereolithography Printing.” Compos. Part A Appl. Sci., 117 276–286 (2019)

Wang, Y, Liu, FG, Xue, XX, “Morphology and Properties of UV-Curing Epoxy Acrylate Coatings Modified with Methacryl-POSS.” Prog. Org. Coat., 78 404–410 (2015)

Toker, RD, Kayaman-Apohan, N, Kahraman, MV, “UV-Curable Nano-Silver Containing Polyurethane Based Organic–Inorganic Hybrid Coatings.” Prog. Org. Coat., 76 (9) 1243–1250 (2013)

Chen, SL, Zhang, SD, Li, YF, et al. “Synthesis and Properties of Novel UV-Curable Hyperbranched Waterborne Polyurethane/Fe3O4 Nanocomposite Films with Excellent Magnetic Properties.” RSC Adv., 5 (6) 4355–4363 (2015)

Birtane, H, Urucu, OA, Yildiz, N, et al. “Statistical Optimization and Selective Uptake of Au(III) from Aqueous Solution Using Carbon Nanotube-Cellulose Based Adsorbent.” Mater. Today Commun., 30 103144 (2022)

Arias-Ferreiro, G, Lasagabaster-Latorre, A, Ares-Pernas, A, et al. “Flexible 3D Printed Acrylic Composites Based on Polyaniline/Multiwalled Carbon Nanotubes for Piezoresistive Pressure Sensors.” Adv. Electron. Mater., 8 2200590 (2022)

Turna, M, Sen, F, Madakbas, S, et al. “Preparation and Characterization of UV-Cured Epoxy Acrylate-based Nanocomposite Coatings Containing Organonanoclay.” Polym. Bull.,. https://doi.org/10.1007/s00289-022-04386-w (2022)

Wang, Y, Cao, ZC, Liu, FG, et al. “Synthesis and Characterization of UV-Curing Epoxy Acrylate Coatings Modified with Organically Modified Rectorite.” J. Coat. Technol. Res., 14 (1) 107–115 (2017)

Dehghan, A, Zohuriaan-Mehr, MJ, Salimi, A, “Rapid Preparation of Epoxy Acrylate-Clay Nanocomposite: Simultaneous Acrylation/Nanoclay Dispersion Under Ultrasonication.” Prog. Org. Coat., 108 44–50 (2017)

Nkeuwa, WN, Riedl, B, Landry, V, “UV-Cured Clay/based Nanocomposite Topcoats for Wood Furniture. Part II: Dynamic Viscoelastic Behavior and Effect of Relative Humidity on the Mechanical Properties.” Prog. Org. Coat., 77 (1) 12–23 (2014)

Xie, H, Wu, QH, Shi, WF, “Preparation of Photopolymerized Nanocomposites Through Intercalating Multifunctional Acrylated Siloxane into Montmorillonite.” Appl. Clay. Sci., 99 164–170 (2014)

Wang, Y, Liu, FG, Xue, XX, “Preparation and Properties of UV-Cured Epoxy Acrylate/Glycidyl-POSS Coatings.” J. Coat. Technol. Res., 14 (3) 665–672 (2017)

Wang, Y, Liu, FG, Xue, XX, “Synthesis and Characterization of UV-Cured Epoxy Acrylate/POSS Nanocomposites.” Prog. Org. Coat., 76 (5) 863–869 (2013)

Gao, JG, Lv, HQ, Zhang, XF, et al. “Synthesis and Properties of Waterborne Epoxy Acrylate Nanocomposite Coating Modified by MAP-POSS.” Prog. Org. Coat., 76 (10) 1477–1483 (2013)

Wang, XF, Wang, X, Song, L, et al. “Preparation and Thermal Stability of UV-Cured Epoxy-based Coatings Modified with Octamercaptopropyl POSS.” Thermochim Acta., 568 130–139 (2013)

Liu, FG, Miao, LQ, Wang, Y, et al. “Green Fabrication of Ultraviolet Curable Epoxy Acrylate-Silica Hybrid Coatings.” Prog. Org. Coat., 109 38–44 (2017)

Yang, ZH, Ni, AQ, Wang, JH, “Synthesis and Characterization of Novel Ultraviolet-Curing Polyurethane Acrylate/Epoxy Acrylate/SiO2 Hybrid Materials via Sol-Gel Reaction.” J. Appl. Polym. Sci., 127 (4) 2905–2909 (2013)

Kardar, P, Ebrahimi, M, Bastani, S, “UV Curing Behavior and Mechanical Properties of Unpigmented and Pigmented Epoxy Acrylate/SiO2 Nanocomposites.” J. Therm. Anal. Calorim., 124 (3) 1425–1430 (2016)

Shang, D, Sun, XY, Hang, JZ, et al. “Preparation and Stability of Silica Sol/TPGDA Dispersions and Its Application in the UV-Curable Hybrid Coatings for Fire Protection.” J. Sol.-Gel. Sci. Technol., 67 (1) 39–49 (2013)

Pan, HF, Song, L, Ma, LY, et al. “Transparent Epoxy Acrylate Resin Nanocomposites Reinforced with Cellulose Nanocrystals.” Ind. Eng. Chem. Res., 51 (50) 16326–16332 (2012)

Xing, WY, Jie, GX, Song, L, et al. “Flame Retardancy and Thermal Properties of Epoxy Acrylate Resin/Alpha-Zirconium Phosphate Nanocomposites Used for UV-Curing Flame Retardant Films.” Mater. Chem. Phys., 125 (1–2) 196–201 (2011)

Xing, WY, Song, L, Lv, XQ, et al. “Preparation, Combustion and Thermal Behaviors of UV-Cured Coatings Containing Organically Modified Alpha-ZrP.” J. Polym. Res., 18 (2) 179–185 (2011)

Uysal, E, Cakir, M, Ekici, B, “Graphene Oxide/Epoxy Acrylate Nanocomposite Production via SLA and Importance of Graphene Oxide Surface Modification for Mechanical Properties.” Rapid. Prototyping J., 27 (4) 682–691 (2021)

Zhang, JH, Zhang, DH, Zhang, AQ, et al. “Poly(methyl methacrylate) Grafted Halloysite Nanotubes and Its Epoxy Acrylate Composites by Ultraviolet Curing Method.” J. Reinf. Plast. Comp., 32 (10) 713–725 (2013)

Li, SY, Qiu, SL, Yu, B, et al. “POSS-Functionalized Polyphosphazene Nanotube: Preparation and Effective Reinforcement on UV-Curable Epoxy Acrylate Nanocomposite Coatings.” RSC Adv., 6 (4) 3025–3031 (2016)

dos Santos, MN, Opelt, CV, Lafratta, FH, et al. “Thermal and Mechanical Properties of a Nanocomposite of a Photocurable Epoxy-Acrylate Resin and Multiwalled Carbon Nanotubes.” Mat. Sci. Eng. A-Struct., 528 (13) 4318–4324 (2011)

Xing, WY, Song, L, Wang, X, et al. “Preparation, Combustion, and Thermal Behavior of UV-Cured Epoxy-based Coatings Containing Layered Double Hydroxide.” Polym. Adv. Technol., 22 (12) 1859–1864 (2011)

Zhou, GD, Wang, WT, Peng, M, “Functionalized Aramid Nanofibers Prepared by Polymerization Induced Self Assembly for Simultaneously Reinforcing and Toughening of Epoxy and Carbon Fiber/Epoxy Multiscale Composite.” Compos. Sci. Technol., 168 312–319 (2018)

Patterson, BA, Malakooti, MH, Lin, JJ, et al. “Aramid Nanofibers for Multiscale Fiber Reinforcement of Polymer Composites.” Compos. Sci. Technol., 161 92–99 (2018)

Jung, J, Sodano, HA, “High Strength Epoxy Nanocomposites Reinforced by Epoxy Functionalized Aramid Nanofibers.” Polymer., 195 122438 (2020)

Tung, HT, Lee, GH, Luan, VH, et al. “Highly Dispersed Aramid Nanofiber-Reinforced Epoxy Nanocomposites by the Sequential Solvent-Exchange Method.” Adv. Compos. Mater.,. https://doi.org/10.1080/09243046.2022.2090045 (2022)

Chen, Y, Yin, Q, Zhang, XM, et al. “Rational Design of Multifunctional Properties for Styrene-Butadiene Rubber Reinforced by Modified Kevlar Nanofibers.” Compos. Part B-Eng., 166 196–203 (2019)

Zhang, XM, Chen, Y, Yin, Q, et al. “Highly Improved Compatibility and Mechanical Properties of Carboxylated Nitrile Rubber/Styrene Butadiene Rubber by Incorporating Modified Kevlar Nanofibers.” Mater Chem Phys., 238 121926 (2019)

Jung, J, Sodano, HA, “Aramid Nanofiber Reinforced Rubber Compounds for the Application of Tire Tread with High Abrasion Resistance and Fuel Saving Efficiency.” ACS Appl. Polym. Mater., 2 (11) 4874–4884 (2020)

Xue, XD, Jiang, K, Yin, Q, et al. “Tailoring the Structure of Kevlar Nanofiber and its Effects on the Mechanical Property and Thermal Stability of Carboxylated Acrylonitrile Butadiene Rubber.” J. Appl. Polym. Sci., 136 (26) 47698 (2019)

Koo, JM, Kim, H, Lee, M, et al. “Nonstop Monomer-to-Aramid Nanofiber Synthesis with Remarkable Reinforcement Ability.” Macromolecules., 522 (3) 923–934 (2019)

Kuang, QX, Zhang, D, Yu, JC, et al. “Toward Record-High Stiffness in Polyurethane Nanocomposites Using Aramid Nanofibers.” J. Phys. Chem. C., 119 (49) 27467–27477 (2015)

He, R, Xie, CJ, Chen, YX, et al. “Robust and Highly Resilient Waterborne Polyurethane-based Composite Aerogels Prepared by Blending with Aramid Nanofibers.” Compos. Sci. Technol., 228 109622 (2022)

Guan, Y, Li, W, Zhang, Y, et al. “Aramid Nanofibers and Poly(vinyl alcohol) Nanocomposites for Ideal Combination of Strength and Toughness via Hydrogen Bonding Interactions.” Compos. Sci. Technol., 144 193–201 (2017)

Park, SA, Eom, Y, Jeon, H, et al. “Aramid Nanofiber Templated In Situ SNAr Polymerization for Maximizing the Performance of All-Organic Nanocomposites.” ACS Macro Lett., 9 (4) 558–564 (2020)

Dong, CC, Guo, P, Yuan, Y, et al. “Aramid Nanomaterials of Various Morphologies: Preparation and Mechanical Property Enhancement.” Front. Chem., 7 939 (2020)

Nasser, J, Zhang, LS, Lin, JJ, et al. “Aramid Nanofiber Reinforced Polymer Nanocomposites via Amide-Amide Hydrogen Bonding.” ACS Appl. Polym. Mater., 2 (7) 2934–2945 (2020)

Wang, Y, Qu, R, Pan, Y, et al. “High-Performance UV-Curable Epoxy Acrylate Nanocomposite Coatings Reinforced with Aramid Nanofibers.” Prog. Org. Coat., 163 106631 (2022)

Shi, YF, Qiu, T, Tuo, XL, “The Bottom-up Synthesis for Aramid Nanofibers: The Influence of Copolymerization.” J. Appl. Polym. Sci., 137 (48) 49589 (2020)

Yan, H, Li, J, Tian, W, et al. “A New Approach to the Preparation of Poly(p-phenylene terephthalamide) Nanofibers.” RSC Adv., 6 (32) 26599–26605 (2016)

Fan, JC, Shi, ZX, Zhang, L, et al. “Aramid Nanofiber-Functionalized Graphene Nanosheets for Polymer Reinforcement.” Nanoscale., 4 (22) 7046–7055 (2012)

Acknowledgments

This study was funded by the National Natural Science Foundation of China (Grant No. 51903114, 52073135) and Natural Science Foundation of Shandong Province (ZR2020ME066).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Luo, Y., Pan, Y. et al. Highly improved UV-shielding and mechanical properties of UV-curable epoxy acrylate nanocomposites by incorporating functionalized aramid nanofibers. J Coat Technol Res 21, 307–317 (2024). https://doi.org/10.1007/s11998-023-00822-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-023-00822-2