Abstract

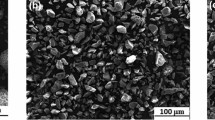

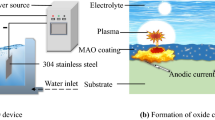

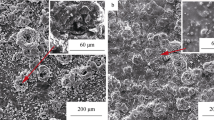

In order to enhance the wear resistance of 6061 aluminum alloy, the MAO-PVA/PTFE self-lubricating composite coating was prepared on the surface of aluminum alloy using microarc oxidation (MAO) technology and solgel technique. Scanning electron microscopy and X-ray diffraction were employed to analyze the morphological properties and structures of the single MAO coating and the composite coating. Energy-dispersive spectroscopy was utilized to examine the elements present on the surface and within the wear track. Ball and disk friction tests were conducted to evaluate the wear resistance of the composite coating. Furthermore, the comprehensive friction performance of the composite coating was investigated across a range of speed variations (1 to 2.5 cm/s) and load variations (1 to 7 N). The test results revealed that the PVA-PTFE film covered the surface of the MAO coating, effectively sealing the micropores. Compared to the single MAO coating, the average coefficient of friction (COF) of the composite coating decreased significantly from 0.549 to 0.139, resulting in improved wear resistance. Moreover, the COF of the composite coating decreased with increasing velocity and load. Subsequently, the wear mechanisms of both the single MAO coating and the composite coating were discussed. The main wear mechanisms observed in the MAO coating were adhesive wear and abrasive wear, while the MAO-PVA/PTFE composite coating exhibited minimal fatigue and oxidation wear. Consequently, the composite coating effectively enhanced the wear resistance of the aluminum alloy, leading to an improved service life.

Similar content being viewed by others

References

Thibault, S, Hug, E, “Corrosion and Wear Mechanisms of Aluminum Alloys Surface Reinforced by Multicharged N-Implantation.” Appl. Surf. Sci., 310 311–316 (2014)

Ye, Z, et al. “Influence of Combined Shot Peening and PEO Treatment on Corrosion Fatigue Behavior of 7A85 Aluminum Alloy.” Appl. Surf. Sci., 486 72–79 (2019)

Luo, Y, et al. “Comparative Study on Surface Influence to Outgassing Performance of Aluminum Alloy.” Appl. Surf. Sci., 502 144166 (2020)

Lameche-Djeghaba, S, et al. “Electrochemical Behaviour of Pure Aluminium and Al–5%Zn Alloy in 3% NaCl Solution.” Arabian J. Sci. Eng., 39 (1) 113–122 (2014)

Jariyaboon, M, et al. “FIB-SEM Investigation of Trapped Intermetallic Particles in Anodic Oxide Films on AA1050 Aluminium.” Anti-Corros. Methods Mater., 58 (4) 173–178 (2011)

Lee, S, Kim, S, “Essential Anti-Corrosive Behavior of Anodized Al Alloy by Applied Current Density.” Appl. Surf. Sci., 481 637–641 (2019)

Nagy, P, et al. “Processing and Characterization of a Multibeam Sputtered Nanocrystalline CoCrFeNi High-Entropy Alloy Film.” Surf. Coat. Technol., 386 125465 (2020)

Luo, Y, et al. “Enhanced Tribological Performance of a Ni/GO-Coated 2024 Alloy.” J. Mater. Eng. Perform., 29 (5) 2947–2956 (2020)

Sun, X, et al. “Revisiting the Electroplating Process for Lithium-Metal Anodes for Lithium-Metal Batteries.” Angew. Chem. Int. Ed .Engl., 59 (17) 6665–6674 (2020)

Goodarzi, DM, Pekkarinen, J, Salminen, A, “Analysis of Laser Cladding Process Parameter Influence on the Clad Bead Geometry.” Weld. World, 61 (5) 883–891 (2017)

Yuan, W, et al. “A Comparative Study on Microstructure and Properties of Traditional Laser Cladding and High-Speed Laser Cladding of Ni45 Alloy Coatings.” Surf. Coat. Technol., 405 126582 (2021)

Gonzalez, R, et al. “A Review of Thermal Spray Metallization of Polymer-Based Structures.” J. Thermal Spray Technol., 25 (5) 897–919 (2016)

Łatka, L, et al. “Review of Functionally Graded Thermal Sprayed Coatings.” Appl. Sci., 10 (15) 5153 (2020)

Gu, Y, et al. “Microstructure and Corrosion Model of MAO Coating on Nano Grained AA2024 Pretreated by Ultrasonic Cold Forging Technology.” J. Alloys Comp., 681 120–127 (2016)

Liu, X, et al. “Investigation of MAO Coating Growth Mechanism on Aluminum Alloy by Two-Step Oxidation Method.” Appl. Surf. Sci., 293 12–17 (2014)

Chen, Q, et al. “Influence of Graphene Particles on the Micro-arc Oxidation Behaviors of 6063 Aluminum Alloy and the Coating Properties.” Appl. Surf. Sci., 423 939–950 (2017)

Li, Z, Di, S, “The Microstructure and Wear Resistance of Microarc Oxidation Composite Coatings Containing Nano-Hexagonal Boron Nitride (HBN) Particles.” J. Mater. Eng. Perform., 26 (4) 1551–1561 (2017)

Rama Krishna, L, Sudha Purnima, A, Sundararajan, G, “A Comparative Study of Tribological Behavior of Microarc Oxidation and Hard-Anodized Coatings.” Wear, 261 (10) 1095–1101 (2006)

Ao, N, et al. “Microstructure and Tribological Behavior of a TiO2/hBN Composite Ceramic Coating Formed via Micro-arc Oxidation of Ti–6Al–4V Alloy.” J. Mater. Sci. Technol., 32 (10) 1071–1076 (2016)

Lv, X, et al. “Tribological Properties of MAO/MoS2 Self-Lubricating Composite Coating by Microarc Oxidation and Hydrothermal Reaction.” Surf. Coat. Technol., 406 126630 (2021)

Ren, L, et al. “Self-Lubricating PEO–PTFE Composite Coating on Titanium.” Metals, 9 (2) 170 (2019)

Chen, Z, et al. “Electroless Plating of Ni-P and Ni-P-PTFE on Micro-Arc Oxidation Coatings for Improved Tribological Performance.” Mater. Res., 25 980 (2022)

Shi, Y, et al. “Tribological Rehydration and Its Role on Frictional Behavior of PVA/GO Hydrogels for Cartilage Replacement under Migrating and Stationary Contact Conditions.” Tribology Lett., 69 (1) 609 (2021)

Shi, L, et al. “Effect of Additives on Structure and Corrosion Resistance of Ceramic Coatings on Mg–Li Alloy by Micro-Arc Oxidation.” Curr. Appl. Phys., 10 (3) 719–723 (2010)

Küçükosman, R, et al. “Investigation of Wear Behavior of Graphite Additive Composite Coatings Deposited by Micro Arc Oxidation-Hydrothermal Treatment on AZ91 Mg Alloy.” Surf. Int., 22 100894 (2021)

Sankara Narayanan, TSN, Park, IS, Lee, MH, “Strategies to Improve the Corrosion Resistance of Microarc Oxidation (MAO) Coated Magnesium Alloys for Degradable Implants: Prospects and Challenges.” Prog. Mater. Sci., 60 1–71 (2014)

Zheng, X, et al. “Probing Local Corrosion Performance of Sol-Gel/MAO Composite Coating on Mg Alloy.” Surf. Coat. Technol., 347 286–296 (2018)

Shao, Z, et al. “Preparation and Properties of Wear-Resistant Carbonized-Ceramic Composite Coating on Pure Aluminum Surface.” Int. J. Appl. Ceramic Technol., 20 (1) 380–394 (2023)

Zhang, K, Yu, S, “Preparation of Wear and Corrosion Resistant Micro-Arc Oxidation Coating on 7N01 Aluminum Alloy.” Surf. Coat. Technol., 388 125453 (2020)

Jia, E, et al. “Polyvinyl Alcohol/Polyethylene Glycol Composite Hydrogel Parceling on Aluminum: Toward More Robust Micro-Arc Oxidation Coatings.” Ceram. Int., 49 (8) 13081–13091 (2023)

Chen, K, et al. “Preparation and Property of High Strength and Low Friction PVA-HA/PAA Composite Hydrogel Using Annealing Treatment.” Mater. Sci. Eng. C, 91 579–588 (2018)

Mamada, K, et al. “Friction Properties of PVA-H/Steel Ball Contact Under Water Lubrication Conditions.” Tribol. Int., 44 (7–8) 757–763 (2011)

Pan, Y, Xiong, D, Ma, R, “A Study on the Friction Properties of Poly(Vinyl Alcohol) Hydrogel as Articular Cartilage Against Titanium Alloy.” Wear, 262 (7–8) 1021–1025 (2007)

Zhou, F, et al. “Friction Characteristic of Micro-Arc Oxidative Al2O3 Coatings Sliding Against Si3N4 Balls in Various Environments.” Surf. Coat. Technol., 202 (16) 3808–3814 (2008)

Shi, Y, Xiong, D, “Microstructure and Friction Properties of PVA/PVP Hydrogels for Articular Cartilage Repair as Function of Polymerization Degree and Polymer Concentration.” Wear, 305 280–285 (2013)

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant No. 52005381).

Author information

Authors and Affiliations

Contributions

ZB and JC developed the initial concept, wrote the initial paper, and provided assistance for data acquisition and data analysis. All authors discussed the results and commented on the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have influenced the work reported here in.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, J., Bai, Z., Xu, J. et al. Preparation and tribological properties of MAO-PVA/PTFE self-lubricating composite coating on aluminum alloy surface. J Coat Technol Res 21, 293–305 (2024). https://doi.org/10.1007/s11998-023-00821-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-023-00821-3