Abstract

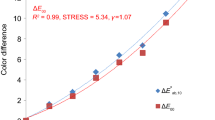

The aim of this article is to propose a model to automatically predict visual judgement of sparkle and graininess of special effect pigments used in industrial coatings. Many applications in the paint and coatings, printing and plastics industry rely on multi-angle color measurements with the aim of properly characterizing the appearance, i.e., the color and texture of the manufactured surfaces. However, when it comes to surfaces containing effect pigments, these methods are in many cases insufficient and it is particularly texture characterization methods that are needed. There are two attributes related to texture that are commonly used: (1) diffuse coarseness or graininess and (2) sparkle or glint impression. In this paper, we analyzed visual perception of both texture attributes using two different psychophysical studies of 38 samples painted with effect coatings including different effect pigments and 31 test persons. Our previous work has shown a good agreement between a study using physical samples with one that uses high-resolution photographs of these sample surfaces. We have also compared the perceived (1) graininess and (2) sparkle with the performance of two commercial instruments that are capable of capturing both attributes. Results have shown a good correlation between the instruments’ readings and the psychophysical studies. Finally, we implemented computational models predicting these texture attributes that have a high correlation with the instrument readings as well as the psychophysical data. By linear scaling of the predicted data using instruments readings, one can use the proposed model for the prediction of graininess and both static and dynamic sparkle values.

Similar content being viewed by others

References

Filip, J, Kolafova, M, Vavra, R, “Perceived Effects of Static and Dynamic Sparkle in Captured Effect Coatings.” The 15th International Conference on Signal Image Technology & Internet Based Systems, IEEE, 2019, pp. 732–737. https://doi.org/10.1109/SITIS.2019.00119.

Pfaff, G, Reynders, P, “Angle-Dependent Optical Effects Deriving from Submicron Structures of Films and Pigments.” Chem. Rev., 99 (7) 1963–1982 (1999)

Maile, F, J, Pfaff, G, Reynders, P, “Effect Pigment—Past, Present and Future.” Prog. Org. Coat., 54 (3) 150–163 (2005)

Pfaff, G, Special Effect Pigments: Technical Basics and Applications. Vincentz Network GmbH & Co KG, Hannover (2008)

Kitaguchi, S, Luo, MR, Kirchner, EJ, van den Kieboom, G-J, “Computational Model for Perceptual Coarseness Prediction.” Conference on Colour in Graphics, Imaging, and Vision, Vol. 2006, Society for Imaging Science and Technology, pp. 278–282 (2006)

Kirchner, E, van den Kieboom, G.-J, Njo, L., Supèr, R, Gottenbos, R, “Observation of Visual Texture of Metallic and Pearlescent Materials.” Color Res. Appl., 32 (4) 256–266 (2007)

Huang, Z, Xu, H, Luo, M, R, Cui, G, Feng, H, “Assessing Total Differences for Effective Samples Having Variations in Color, Coarseness, and Glint.” Chin. Opt. Lett., 8 (7) 717–720 (2010)

Rentschler, T, “Measuring Sparkling Blues Without Blues.” Eur. Coat. J., 12 78–83 (2011)

Dekker, N, Kirchner, E, Super, R, van den Kieboom, G, Gottenbos, R, “Total Appearance Differences for Metallic and Pearlescent Materials: Contributions from Color and Texture.” Color Res. Appl., 36 (1) 4–14 (2011)

Kirchner, E, Ravi, J, “Setting Tolerances on Color and Texture for Automotive Coatings.” Color Res. Appl., 39 (1) 88–99 (2014)

Kirchner, E, Van der Lans, I, Perales, E, Martínez-Verdú, F, Campos, J, Ferrero, A, “Visibility of Sparkle in Metallic Paints.” JOSA A, 32 (5) 921–927 (2015)

Wang, ZW, Luo, MR, “Looking into Special Surface Effects: Diffuse Coarseness and Glint Impression.” Color. Technol., 132 (2) 153–161 (2016)

Seubert, C, Nichols, M. Frey, J, Shtein, M, Thouless, M, “The Characterization and Effects of Microstructure on the Appearance of Platelet-Polymer Composite Coatings.” J. Mater. Sci., 51 (5) 2259–2273 (2016)

Seubert, C, Nichols, M, Kappauf, C, Ellwood, K, Shtein, M, Thouless, M, “A Hybrid Ray-wave Optics Model to Study the Scattering Behavior of Silver Metallic Paint Systems.” J. Coat. Technol. Res., 15 (3) 471–480 (2018)

Gómez, O, Perales, E, Chorro, E, Viqueira, V, Martínez-Verdú, FM, “Visual and Instrumental Correlation of Sparkle by the Magnitude Estimation Method.” Appl. Opt., 55 (23) 6458–6463 (2016)

Iacomussi, P, Radis, M, Rossi, G, “Brightness and Sparkle Appearance of Goniochromatic Samples.” Proceedings of the IS&T International Symposium on Electronic Imaging, MMRMA, pp. 365.1–365.6 (2016)

Amookht, S, Kandi, SG, Mahdavian, M, “Quantification of Perceptual Coarseness of Metallic Coatings Containing Aluminum Flakes Using Texture Analysis and Visual Assessment Methods.” Prog. Org. Coat., 137 105375 (2019)

Watanabe, S, “One-Shot Multi-angle Measurement Device for Evaluating the Sparkle Impression.” Electron. Imaging, 2020 (5) 60401–1 (2020)

Perales, E, Micó-Vicent, B, Huraibat, K, Viqueira, V, “Evaluating the Graininess Attribute by Visual Scaling for Coatings with Special-Effect Pigments.” Coatings, 10 (4) 316 (2020)

Ferrero, A, Basic, N, Campos, J, Pastuschek, M, Perales, E, Porrovecchio, G, Šmid, M, Schirmacher, A, Velázquez, J, Martínez-Verdú, F, “An Insight into the Present Capabilities of National Metrology Institutes for Measuring Sparkle.” Metrologia, 57 (6) 065029 (2020)

Günther, J, Chen, T, Goesele, M, Wald, I, Seidel, H-P, “Efficient Acquisition and Realistic Rendering of Car Paint.” VMV pp. 487–494 (2005)

Ershov, S, Kolchin, K, Myszkowski, K, “Rendering Pearlescent Appearance Based on Paint-Composition Modelling.” Comput. Graph. Forum, 20 (3) 227–238 (2001)

Ďurikovič, R, Martens, WL, “Simulation of Sparkling and Depth Effect in Paints.” Proceedings of the 19th Spring Conference on Computer Graphics, SCCG ’03, ACM, New York, NY, USA, pp. 193–198 (2003)

Ergun, S, Önel, S, Ozturk, A, “A General Micro-Flake Model for Predicting the Appearance of Car Paint.” Proceedings of the Eurographics Symposium on Rendering: Experimental Ideas & Implementations, EGSR ’16, pp. 65–71 (2016)

Ďurikovič, R, Mihálik, A, “Metallic Paint Appearance Measurement and Rendering.” J. Appl. Math. Stat. Inf., 9 (2) 25–39 (2007)

Rump, M, Muller G, Sarlette, R, Koch, D, Klein,R, “Photo-Realistic Rendering of Metallic Car Paint from Image-Based Measurements.” Comput. Graph. Forum, 27 (2) 527–536 (2008)

Rump, M, Sarlette, R, Klein, R, “Efficient Resampling, Compression and Rendering of Metallic and Pearlescent Paint.” In: Magnor, M, Rosenhahn, B, Theisel H (eds.), Vision, Modeling, and Visualization, pp. 11–18 (2009)

Golla, T, Klein, R, “An Efficient Statistical Data Representation for Real-Time Rendering of Metallic Effect Car Paints.” In: Barbic, J. D’Cruz, M, Latoschik, ME, Slater, M, Bourdot P, (eds.) Virtual Reality and Augmented Reality, Springer International Publishing, pp. 51–68 (2017)

Lans, Ivd, Kirchner, E, Half, A, “Accurate Appearance-Based Visualization of Car Paints.” Proceedings of International Conference on Computer Graphics, pp. 17–23 (2012)

Kirchner, E, Ravi, J, “Predicting and Measuring the Perceived Texture of Car Paints.” In: Padilla, S, Chantler, MJ, Harris, JM, & Pointer, MR Lulu (eds.) Predicting Perceptions: Proceedings of the 3rd International Conference on Appearance, pp. 25–28 (2012)

Ferrero, A, Campos, J, Rabal, A, Pons, A, “A Single Analytical Model for Sparkle and Graininess Patterns in Texture of Effect Coatings.” Opt. Express, 21 (22) 26812–26819 (2013)

Kirchner, E, van der Lans, I, Koeckhoven, P, Huraibat, K, Martínez-Verdú, F, Perales, E, Ferrero, A, Campos, J, “Real-time Accurate Rendering of Color and Texture of Car Coatings.” Electron. Imaging Color Imaging XXIV: Display. Process. Hardcopy Appl., pp. 76–1–76–6(6) (2019). https://doi.org/10.2352/ISSN.2470-1173.2019.14.COLOR-076.

McCanny, CS, “Observation and Measurement of the Appearance of Metallic Materials. Part. 1. Macro Appearance.” Color Res. Appl., 21 (4) 292–304 (1996)

E2194-12, A, Standard Practice for Multiangle Color Measurement of Metal Flake Pigmented Materials. West Conshohocken PA, ASTM International (2012)

E2539-12, A, Standard Practice for Multiangle Color Measurement of Interference Pigments. West Conshohocken PA, ASTM International (2012)

BYK-mac i COLOR product information, BYK-Gardner GmbH, https://www.byk-instruments.com/cz/en/color/byk-mac-i-metalliccolor/c/2338, accessed 14/6/2020

MA-T12 multiangle spectrophotometer product information, X-Rite, https://www.xrite.com/categories/portable-spectrophotometers/ma-t12, accessed 14/6/2020

Keelan, B, “ISO 20462: A Psychophysical Image Quality Measurement Standard.” Proceedings of the SPIE, vol. 5294, SPIE 2003, pp. 181–189 (2003)

Filip, J, Vávra, R, Haindl, M, Zid, P, Krupicka, M, Havran, V, “BRDF Slices: Accurate Adaptive Anisotropic Appearance Acquisition.” Proceedings of the 26th IEEE Conference on Computer Vision and Pattern Recognition, CVPR 2013 pp. 4321–4326 (2013)

Hayes, AF, Krippendorff, K, “Answering the Call for a Standard Reliability Measure for Coding Data.” Commun. Methods Meas., 1 (1) 77–89 (2007)

ITU, ITU-R.REC.P.910. Subjective Audivisual Quality Assessment Methods for Multimedia Applications, Tech. Rep., International Telecommunication Union (2008)

Kitaguchi, S, Luo, MR, Westland, S, Kirchner, EJ, van den Kieboom, G-J, “Assessing Texture Difference for Metallic Coating on Different Media.” Color and Imaging Conference, Vol. 2006, Society for Imaging Science and Technology, pp. 197–202 (2006)

Crumey, A, “Human Contrast Threshold and Astronomical Visibility.” Mon. Not. R. Astron. Soc., 442 (3) 2600–2619 (2014)

Ferrero, A, Velázquez, JL, Perales, E, Campos, J, Verdú, FMM, “Definition of a Measurement Scale of Graininess from Reflectance and Visual Measurements.” Opt. Express, 26 (23) 30116–30127 (2018). https://doi.org/10.1364/OE.26.030116.

Welch, P, “The Use of Fast Fourier Transform for the Estimation of Power Spectra: A Method Based on Time Averaging Over Short, Modified Periodograms.” IEEE Trans. Audio Electroacust., 15 (2) 70–73 (1967). https://doi.org/10.1109/TAU.1967.1161901.

Acknowledgments

The authors would like to thank all anonymous observers for their valuable time devoted to our psychophysical experiments.

Funding

This research has been partially supported by the Czech Science Foundation Grant GA17-18407S.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Filip, J., Vávra, R., Kolafová, M. et al. Assessment of sparkle and graininess in effect coatings using a high-resolution gonioreflectometer and psychophysical studies. J Coat Technol Res 18, 1511–1530 (2021). https://doi.org/10.1007/s11998-021-00518-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-021-00518-5