Abstract

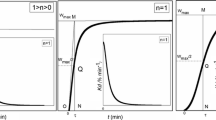

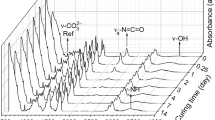

Drying process paths, i.e., time-dependent trajectories of solution compositions on a phase diagram, were examined for coatings of a water-immiscible acrylic monomer dissolved in ethanol and exposed to humidity. The absorption of water vapor quenched the solution into a thermodynamic nonequilibrium state and promoted a spontaneous phase separation when the water content in the solution exceeded a critical value. A simultaneous mass-loss and heat-flux measurement technique was proposed and adapted for phase-separating coatings to determine the evaporation rates of two volatile components with different latent heats of vaporization. The measured drying paths agreed with those predicted from a drying model that takes into account the gas-diffusion-limited evaporation and composition-dependent activities. The numerical predictions also revealed that the pseudo-azeotrope determined the critical drying conditions, under which any drying paths on the phase diagram did not cross the two-phase region, and thus the drying solutions remained stable.

Similar content being viewed by others

References

Lee, JY, Yi, MS, Jeong, HC, Kim, JT, Nam, JH, Noh, SM, Jung, HW, “Characterization of Clearcoats Containing Phosphoric Acid-Functionalized Acrylic Polyols for Automotive Precoated Metal Sheet Coatings.” J. Coat. Technol. Res., 11 697–710 (2014)

Li, T, Zhang, P, Chen, B, Liu, S, Deng, J, “Synthesis and Properties of UV-Curable Waterborne Urethane Modified Acrylic Coatings with Varying Vinyl Content.” J. Appl. Polym. Sci., 137 49384 (2020)

Yu, YY, Chen, PK, “Nanocomposites of Polymer and Inorganic Nanoparticles Prepared by Focused Microwave Polymerization for Optical Thin Films Applications.” Thin Solid Films, 544 48–53 (2013)

Yao, B, Zhao, H, Wang, L, Liu, Y, Zheng, C, Li, H, Sun, C, “Synthesis of Acrylate-Based UV/Thermal Dual-Cure Coatings for Antifogging.” J. Coat. Technol. Res., 15 (1) 149–158 (2018)

Degli Esposti, M, Pilati, F, Bondi, M, de Niederhäusern, S, Iseppi, R, Toselli, M, “Preparation, Characterization, and Antibacterial Activity of Photocured Thymol-Doped Acrylic Resins.” J. Coat. Technol. Res., 10 371–379 (2013)

Wang, S, Wu, Y, Dai, J, Teng, N, Peng, Y, Cao, L, Liu, X, “Making Organic Coatings Greener: Renewable Resource, Solvent-Free Synthesis, UV Curing and Repairability.” Eur. Polym. J., 123 109439 (2020)

Dabral, M, Francis, LF, Scriven, LE, “Drying Process Paths of Ternary Polymer Solution Coating.” AIChE J., 48 25–37 (2002)

Dillon, P, Cronin, K, Byrne, EP, “Evaporation Maps for Non-ideal Ternary Mixtures.” Chem. Eng. Sci., 126 641–659 (2015)

Riede, T, Schlünder, EU, “Selective Evaporation of a Ternary Mixture Containing One Nonvolatile Component with Regard to Drying Processes.” Chem. Eng. Process., 28 151–163 (1990)

Viduarre, M, Martinez, J, “Continuous Drying of a Solid Wetted with Ternary Mixtures.” AIChE J., 43 681–692 (1997)

Martinez, J, Setterwall, F, “Gas-Phase Controlled Convective Drying of Solids Wetted with Multicomponent Mixtures.” Chem. Eng. Sci., 46(9) 2235–2252 (1991)

Thurner, F, Schlünder, EU, “Progress Towards Understanding the Drying of Porous Materials Wetted with Binary Mixtures.” Chem. Eng. Process., 20 9–25 (1989)

Huang, YS, Sundmacher, K, Qi, Z, Schlünder, EU, “Residue Curve Maps of Reactive Membrane Separation.” Chem. Eng. Sci., 59 2863–2879 (2004)

Scheepers, F, Stähler, A, Stähler, M, Carmo, M, Lehnert, W, Stolten, D, “Steering and In Situ Monitoring of Drying Phenomena During Film Fabrication.” J. Coat. Technol. Res., 16 1213–1221 (2019)

Putranto, A, Chen, XD, “Drying of a System of Multiple Solvents: Modeling by the Reaction Engineering Approach.” AIChE J., 62 2144–2215 (2016)

Shojaie, SS, Krantz, WB, Greenberg, AR, “Dense Polymer Film and Membrane Formation via the Dry-Cast Process Part I. Model Development.” J. Membr. Sci., 94 255–280 (1994)

Altinkaya, SA, Ozbas, B, “Modeling of Asymmetric Membrane Formation by Dry-Casting Method.” J. Membr. Sci., 230 71–89 (2004)

Prakash, SS, Francis, LF, Scriven, LE, “Microstructure Evolution in Dry Cast Cellulose Acetate Membranes by Cryo-SEM.” J. Membr. Sci., 283 328–338 (2006)

Kuo, CY, Su, SL, Tsai, HA, Wang, DM, Lai, JY, “Formation and Evolution of a Bicontinuous Structure of PMMA Membrane During Wet Immersion Process.” J. Membr. Sci., 315 187–194 (2008)

Pervin, R, Ghosh, P, Basavaraj, MG, “Tailoring Pore Distribution in Polymer Films via Evaporation Induced Phase Separation.” RSC Adv., 9 15593–15605 (2019)

Raupp, SM, Kitz, PG, Siebel, DK, Wunsch, A, Merklein, L, Scharfer, P, Schabel, W, “Modeling of Interdiffusion in Poly(Vinyl Acetate)–Poly(Methyl Methacrylate)–Toluene Multicomponent Systems.” J. Appl. Polym. Sci., 136 47092 (2019)

Yoshihara, H, Yamamura, M, “Concentration Profiles in Phase-Separating Photocuring Coatings.” J. Coat. Technol. Res., 16 1629–1636 (2019)

Gracia-Medrano-Bravo, VA, Gröne, J, Baesch, S, Scharfer, P, Schabel, W, “Influence of Particle Shape on the Drying Regime Maps for Platelike Particle-Polymer Composites.” Langmuir, 36 6245–6253 (2020)

Gracia-Medrano-Bravo, VA, Merklein, L, Oberle, N, Batora, M, Scharfer, P, Schabel, W, “Determination of Binary Interaction Parameters for Ternary Polymer-Polymer-Solvent Systems Using Raman Spectroscopy.” Adv. Mater. Technol., 6(2) 2000149 (2021)

Tchakalova, V, Zemb, T, Benczédi, D, “Evaporation Triggered Self-assembly in Aqueous Fragrance-Ethanol Mixtures and Its Impact on Fragrance Performance.” Colloids Surf. A, 460 414–421 (2014)

Yamamura, M, Ohara, K, Mawatari, Y, Kage, H, “Measuring the Drying Rate of Liquid Film Coatings Using Heat Flux Method.” Drying Technol., 27 817–820 (2009)

Fishenden, M, Saunders, OA, Introduction to Heat Transfer 180. Clarendon Press, Oxford (1980)

Matsuyama, H, Teramoto, M, Uesaka, T, “Membrane Formation and Structure Development by Dry-Cast Process.” J. Membr. Sci., 135 271–288 (1997)

Yamamura, M, Horiuchi, K, Kajiwara, T, Adachi, K, “Decrease in Solvent Evaporation Rate Due to Phase Separation in Polymer Films.” AIChE J., 48 2711–2714 (2002)

Yamamura, M, Yamakawa, T, Nasu, T, Orihashi, K, Mawatari, Y, Kage, H, “Effects of Polymer End Groups on the Drying Rates of Phase Separating Coatings.” Chem. Eng. Process., 68 55–59 (2013)

Yamamura, M, Yoshihara, H, Mawatari, Y, Kage, H, “Enhanced Solvent Drying of Liquid Film Coatings by Fluorine-Base Polymeric Surfactant Addition.” J. Chem. Eng. Jpn., 45 441–443 (2012)

Fredenslund, A, Jones, RL, Prausnitz, JM, “Group-Contribution Estimation of Activity Coefficients in Nonideal Liquid Mixtures.” AIChE J., 21 1086–1099 (1975)

Fredenslund, A, Gmehling, J, Rasmussen, P, Vapor-Liquid Equilibria Using UNIFAC a Group-Contribution Method. Elsevier, Amsterdam (1977)

Yamamura, M, Eikai, S, Mawatari, Y, Kage, H, “Drying-Induced Hierarchical Dimple Patterns on Partially Miscible Polymeric Films Under Ordered Convections.” Drying Technol., 31 1212–1218 (2013)

Widawski, G, Rawiso, M, François, B, “Self-Organized Honeycomb Morphology of Star-Polymer Polystyrene Films.” Nature, 369 387–389 (1994)

Aynard, A, Pessoni, L, Billon, L, “Directed Self-assembly in “Breath Figure” Templating of Block Copolymers Followed by Soft Hydrolysis-Condensation: One Step Towards Synthetic Bio-inspired Silica Diatoms Exoskeleton.” Polymer, 210 123047 (2020)

Acknowledgments

The author wishes to thank Hirokazu Ohya and Mitsuru Shoji for their technical assistance with the experiments. The author acknowledges the financial support of the Japan Society for the Promotion of Science (JSPS) KAKENHI (20H02507) Grant-in-Aid for Scientific Research B.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This paper was presented at the 2020 International Society of Coatings Science and Technology Conference that was held virtually September 20–23, 2020.

Supplementary Information

Below is the link to the electronic supplementary material.

11998_2021_483_MOESM1_ESM.pdf

Variations in the (a) solvent mass and (b) heat flux of evaporating monomer thin film with drying time. The initial ethanol content and the surface temperature of the substrate were 10 g-EtOH/g-DPHA and 26.0°C, respectively. The vapor saturation of water was Sw = 0.49. The solvent mass decreased almost linearly with time in early evaporation stages, i.e., in a constant-rate period. The measured heat flux maintained an almost constant value for a certain drying time and then decreased as the evaporation rate decreased. The slope of the dashed line represents the initial evaporation rate. (PDF 330 kb)

Rights and permissions

About this article

Cite this article

Yamamura, M. Drying paths of phase-separating solution coatings exposed to humidity. J Coat Technol Res 19, 15–23 (2022). https://doi.org/10.1007/s11998-021-00483-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-021-00483-z