Abstract

The mechanical properties of pigmented coating layers are important in a variety of applications. However, the large number of parameters that influence these properties as well as the numerous types of deformations challenge the prediction of the performance of these systems. A discrete element method (DEM) is proposed to predict the mechanical properties of paper coating layers that have a range of starch and latex content. The model is developed in both 2D and 3D and is adapted to tensile and flexural deformations. The model predictions are compared to experimental results in the literature. The predictions are generally good for the moduli and the strain at failure of the systems, but underpredict the maximum stress. This result may be caused by the complex particle size distribution of the experimental systems or by the impact of the brittleness of the starch when making the freestanding films.

Similar content being viewed by others

References

Kirsch, S, Pfau, A, Frechen, T, Schrof, W, Pföhler, P, Francke, D, “Scrub Resistance of Highly Pigmented Paints: A Study on Abrasion Mechanisms of Different Scrub Techniques.” Prog. Org. Coat., 43 (1–3) 99–110 (2001)

Hu, L, Wu, H, La Mantia, F, Yang, Y, Cui, Y, “Thin, Flexible Secondary Li-Ion Paper Batteries.” ACS Nano, 4 (10) 5843–5848 (2010)

Su, X, Wu, Q, Li, J, Xiao, X, Lott, A, Lu, W, Sheldon, BW, Wu, J, “Silicon-Based Nanomaterials for Lithium-Ion Batteries: A Review.” Adv. Energy Mater., 4 (1) 1300882 (2014)

Barbier, C, Rättö, P, Hornatowska, J. “Coating Models for an Analysis of Cracking Behavior Between Folded Paper and Creased Board.” 12th TAPPI Advanced Coating Fundamentals Symposium Proceedings, pp. 5–16. TAPPI Press, Atlanta, GA (2012).

Sim, K, Youn, HJ, Oh, KD, Lee, HL, Han, CS, Yeu, SU, Lee, YM, “Fold Cracking of Coated Paper: The Effect of Pulp Fiber Composition and Beating.” Nord. Pulp Pap. Res. J., 27 (2) 445–450 (2012)

Oh, K, Seo, D, Youn, HJ, Lee, YM, Yeu, SU, Lee, HL, “Effects of Coating Composition and Folding Direction on the Fold Cracking of Coated Paper.” Nord. Pulp Pap. Res. J., 31 (2) 347–353 (2016)

Rättö, P, Hornatowska, J, “The Influence of Coating Colour Composition on the Crack Area After Creasing.” Nord. Pulp Pap. Res. J., 25 (4) 488–494 (2010)

Rättö, P, Hornatowska, J, Changhong, X, Terasaki, O, “Cracking Mechanisms of Clay-Based and GCC-Based Coatings.” Nord. Pulp Pap. Res. J., 26 (4) 485–492 (2011)

Alam, P, Toivakka, M, Carlsson, R, Salminen, P, Sandas, S, “Balancing Between Fold-Crack Resistance and Stiffness.” J. Compos. Mater., 43 (11) 1265–1283 (2009)

Alam, P, Byholm, T, Kniivilä, J, Sinervo, L, Toivakka, M, “Calculating the Permeability of Model Paper Coating Structures Comprising Incongruent Particle Shapes and Sizes.” Microporous Mesoporous Mater., 117 (3) 685–688 (2009)

Barbier, C, Larsson, P-L, Ostlund, S, “Numerical Investigation of Folding of Coated Papers.” Compos. Struct., 67 383–394 (2005)

Rättö, P, “Mechanical Properties of Coating Layers.” J. Pulp Pap. Sci., 30 (12) 335–340 (2004)

Toivakka, M, Alam, P, Touaiti, F, Oravilahti, A, Oravilahti, T, Knuutinen, J, Nilsson, R, Pahlevan, M, Ahokas, M, Wilen, C, “Understanding Coating Strength at the Molecular and Microscopic Level.” TAPPI J., 14 (6) 373–383 (2015)

Donzé, FV, Richefeu, V, Magnier, SA, “Advances in Discrete Element Method Applied to Soil, Rock and Concrete Mechanics.” Electron. J. Geotech. Eng., 8 (1) 44–57 (2009)

Ketterhagen, WR, Curtis, JS, Wassgren, CR, Hancock, BC, “Predicting the Flow Mode from Hoppers Using the Discrete Element Method.” Powder Technol., 195 (1) 1–10 (2009)

Vu-Quoc, L, Zhang, X, Walton, OR, “A 3-D Discrete-Element Method for Dry Granular Flows of Ellipsoidal Particles.” Comput. Methods Appl. Mech. Eng., 187 (3–4) 483–528 (2000)

Toivakka, M, Bousfield, D, “Modeling of Coating Layer Mechanical Properties.” TAPPI Advanced Coating Fundamentals Symposium, pp. 197–211. TAPPI Press, Atlanta GA (2001).

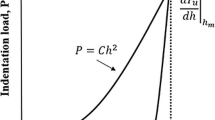

Azadi, P, Farnood, R, Yan, N, “Discrete Element Modeling of the Mechanical Response of Pigment Containing Coating Layers Under Compression.” Comput. Mater. Sci., 42 50–56 (2008)

Varney, D, Bousfield, DW, “Discrete Element Method to Predict Coating Failure Mechanisms.” TAPPI J., 17 (1) 21–30 (2018)

Zhu, Z, Salminen, P, Chen, G, Toivakka, M, “Mechanical Properties of Pigment Coating Composites Containing Starch.” 13 th TAPPI Advanced Coating Fundamentals Symposium, TAPPI Press, Atlanta GA (2014)

Najafi, SMH, Tajvidi, M, Bousfield, DW, “Production and Mechanical Characterization of Free-Standing Pigmented Paper Coating Layers with Latex and Starch as Binder.” Prog. Org. Coat., 123 138–145 (2018)

Chen, G, Zhu, ZJ, Salminen, P, Toivakka, M, “Structure and Mechanical Properties of Starch/Styrene-Butadiene Latex Composites.” Adv. Mater. Res., 936 74–81 (2014)

Najafi, SMH, “Influence of Coating Mechanical Properties on the Crack at the Fold Problem.” Ph.D. thesis, University of Maine. https://digitalcommons.library.umaine.edu/etd/2950 (2019)

Byholm, T, Toivakka, M, Westerholm, J, “Effective Packing of 3-Dimensional Voxel-Based Arbitrarily Shaped Particles.” Powder Technol., 196 (2) 139–146 (2009)

Vidal, D, Ridgway, C, Pianet, G, Schoelkopf, J, Roy, R, Bertrand, F, “Effect of Particle Size Distribution and Packing Compression on Fluid Permeability as Predicted by Lattice-BOLTZMANN Simulations.” Comput. Chem. Eng., 33 (1) 256–266 (2009)

Acknowledgments

We like to thank the sponsors of the University of Maine Paper Surface Science Program for their discussions and support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Varney, D., Toivakka, M. & Bousfield, D. Discrete element method to predict the mechanical properties of pigmented coatings. J Coat Technol Res 16, 1683–1689 (2019). https://doi.org/10.1007/s11998-019-00255-w

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-019-00255-w