Abstract

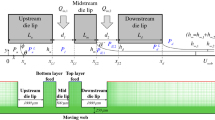

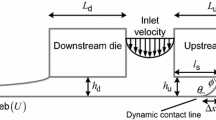

Slot coating of particle suspensions is commonly used in the manufacturing of a wide variety of products. An important limit in this process is known as low-flow limit, which refers to the minimum wet film thickness that can be coated at a given substrate velocity. Recent studies have shown that shear-induced particle migration leads to a highly non-uniform particle distribution in the coating bead, playing an important role in the flow dynamics in slot coating of particulate systems. In this work, we extend the previous analyses to investigate the effects of particle migration on the low-flow limit in slot coating of particle suspensions at both dilute and concentrated conditions. As a first approximation, the suspension is modeled as a Newtonian liquid with a concentration-dependent viscosity, and shear-induced particle migration is described according to the diffusive flux model. The resulting set of governing equations is solved with a stabilized finite element method coupled with the elliptic mesh generation method for the free-boundary problem. The results show that particle migration changes the liquid viscosity near the downstream meniscus and strongly affects the force balance that sets the critical operating conditions at the low-flow limit. Remarkably, it was found that particle migration enlarges the operating window of the process when the suspensions are compared to a Newtonian liquid with the same bulk properties, especially at high concentrations.

Similar content being viewed by others

References

Ding, X, Liu, J, Harris, TAL, “A Review of the Operating Limits in Slot Die Coating Processes.” AIChE J., 62 (7) 2508–2524 (2016)

Carvalho, MS, Kheshgi, HS, “Low-Flow Limit in Slot Coating: Theory and Experiments.” AIChE J., 46 (10) 1907–1917 (2000)

Ruschak, KJ, “Limiting Flow in a Pre-metered Coating Device.” Chem. Eng. Sci., 31 (11) 1057–1060 (1976)

Higgins, BG, Scriven, LE, “Capillary Pressure and Viscous Pressure Drop Set Bounds on Coating Bead Operability.” Chem. Eng. Sci., 35 (3) 673–682 (1980)

Lee, K-Y, Liu, L-D, Liu, T-J, “Minimum Wet Thickness in Extrusion Slot Coating.” Chem. Eng. Sci., 47 (7) 1703–1713 (1992)

Chang, Y-R, Chang, H-M, Lin, C-F, Liu, T-J, Wu, P-Y, “Three Minimum Wet Thickness Regions of Slot Die Coating.” J. Colloid Interface Sci., 308 (1) 222–230 (2007)

Benkreira, H, Ikin, JB, “Slot Coating Minimum Film Thickness in Air and in Rarefied Helium.” Chem. Eng. Sci., 150 66–73 (2016)

Romero, OJ, Suszynski, WJ, Scriven, LE, Carvalho, MS, “Low-Flow Limit in Slot Coating of Dilute Solutions of High Molecular Weight Polymer.” J. Non-Newton. Fluid Mech., 118 (2–3) 137–156 (2004)

Romero, OJ, Scriven, LE, Carvalho, MS, “Slot Coating of Mildly Viscoelastic Liquids.” J. Non-Newton. Fluid Mech., 138 (2–3) 63–75 (2006)

Bajaj, M, Prakash, JR, Pasquali, M, “A Computational Study of the Effect of Viscoelasticity on Slot Coating Flow of Dilute Polymer Solutions.” J. Non-Newton. Fluid Mech., 149 (1–3) 104–123 (2008)

Ning, C-Y, Tsai, C-C, Liu, T-J, “The Effect of Polymer Additives on Extrusion Slot Coating.” Chem. Eng. Sci., 51 (12) 3289–3297 (1996)

Yang, CK, Wong, DSH, Liu, TJ, “The Effects of Polymer Additives on the Operating Windows of Slot Coating.” Polym. Eng. Sci., 44 (10) 1970–1976 (2004)

Chu, V, Tsai, M-Z, Chang, Y-R, Liu, T-J, Tiu, C, “Effects of the Molecular Weight and Concentration of Poly(Vinyl Alcohol) on Slot Die Coating.” J. Appl. Polym. Sci., 116 (2) 654–662 (2010)

Huang, Y-C, Wang, T-Z, Liu, T-J, Tiu, C, “Operating Window of Solution Casting. II. Non-newtonian Fluids.” J. Appl. Polym. Sci., 132 (5) 41411 (2015)

Campana, DM, Silva, LDV, Carvalho, MS, “Slot Coating Flows of Non-colloidal Particle Suspensions.” AIChE J., 63 (3) 1122–1131 (2017)

Siqueira, IR, Rebouças, RB, Carvalho, MS, “Particle Migration and Alignment in Slot Coating Flows of Elongated Particle Suspensions.” AIChE J., 63 (7) 3187–3198 (2017)

Araujo, SB, Carvalho, MS, “Sedimentation and Marangoni Stress in Slot Coating Flow of Particle Suspension.” J. Non-Newton. Fluid Mech., 247 53–61 (2017)

Rebouças, RB, Siqueira, IR, Carvalho, MS, “Slot Coating Flow of Particle Suspensions: Particle Migration in Shear Sensitive Liquids.” J. Non-Newton. Fluid Mech., 258 22–31 (2018)

Cardinal, CM, Jung, YD, Ahn, KH, Francis, LF, “Drying Regime Maps for Particulate Coatings.” AIChE J., 56 2769–2780 (2010)

Buss, F, Roberts, CC, Crawford, KS, Peters, K, Francis, LF, “Effect of Soluble Polymer Binder on Particle Distribution in a Drying Particulate Coating.” J. Colloid Interface Sci., 359 (1) 112–120 (2011)

Price, KK, Wu, Y, McCormick, AV, Francis, LF, Frisbie, CD, “Stress Development in Hard Particle Coatings in the Absence of Lateral Drying.” J. Am. Ceram. Soc., 98 (7) 2214–2222 (2015)

Baesch, S, Scharfer, P, Schabel, W, Francis, LF, “Influence of the Drying Conditions on the Particle Distribution in Particle-Filled Polymer Films: Predictive Simulation of the Particle Distribution During Drying.” J. Compos. Mater., 51 (24) 3391–3403 (2017)

Wu, Y, Francis, LF, “Effect of Particle Size Distribution on Stress Development and Microstructure of Particulate Coatings.” J. Coat. Technol. Res., 14 (2) 455–465 (2017)

Santamaría-Holek, I, Mendoza, CI, “The Rheology of Concentrated Suspensions of Arbitrarily-Shaped Particles.” J. Colloid Interface Sci., 346 118–126 (2010)

Phillips, RJ, Armstrong, RC, Brown, RA, Graham, AL, Abbott, JR, “A Constitutive Equation for Concentrated Suspensions that Accounts for Shear-Induced Particle Migration.” Phys. Fluids A Fluid Dyn., 4 30–40 (1992)

Siqueira, IR, Carvalho, MS, “Particle Migration in Planar Die-Swell Flows.” J. Fluid Mech., 825 49–68 (2017)

de Santos Avila, JM, “Two-Phase Cocurrent Downflow Through Constricted Passages.” Ph.D. thesis, University of Minnesota, Minneapolis, United States, 1991

Pasquali, M, Scriven, LE, “Free Surface Flows of Polymer Solutions with Models Based on the Conformation Tensor.” J. Non-Newton. Fluid Mech., 108 (1–3) 363–409 (2002)

Chu, W-B, Yang, J-W, Wang, Y-C, Liu, T-J, Tiu, C, Guo, J, “The Effect of Inorganic Particles on Slot Die Coating of Poly(Vinyl Alcohol) Solutions.” J. Colloid Interface Sci., 297 215–225 (2006)

Acknowledgments

This work was supported by the Brazilian Research Council (CNPq) and the Industrial Partnership for Research in Interfacial & Materials Engineering of the University of Minnesota (IPRIME).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Siqueira, I.R., Carvalho, M.S. A computational study of the effect of particle migration on the low-flow limit in slot coating of particle suspensions. J Coat Technol Res 16, 1619–1628 (2019). https://doi.org/10.1007/s11998-019-00196-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-019-00196-4