Abstract

Two polyurethanes were prepared through the reaction of 1,6-diisocyanatohexane (HDI) with two kinds of alcoholates. The first alcoholate was synthesized from alcoholized lactide (PLA) and dodecafluoroheptyl methacrylate (DFHMA) with the solid super acid (SO42−/ZrO) acting as the catalyst, and the other alcoholate was a mixture of PLA and DFHMA. The composition and structure of these two polyurethanes were investigated by infrared spectroscopy (FTIR) and differential scanning calorimetry (DSC). The mass loss, attachment of bacteria and algae, and the water contact angle were used to evaluate the degradable and antifouling performance of the two polyurethane coatings. The results showed that the maximum contact angle of PLIPFI reached 129°, its mass loss was higher than 10% in 65 days, and after 65 days, the mass loss appeared to be stable, and the antiadhesion performance of the polyurethanes coatings was also enhanced. All of these results indicated that the PU modified with a graft segment may be promising for obtaining antifouling materials that not only can resist the adhesion of microorganisms but also show self-renewal.

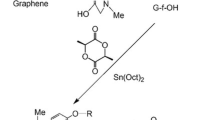

Graphical Abstract

Similar content being viewed by others

References

Callow, JA, Callow, ME, “Trends in the Development of Environmentally Friendly Fouling-Resistant Marine Coatings.” Nat. Commun., 2 244 (2011)

Thomas, KV, Brooks, S, “The Environmental Fate and Effects of Antifouling Paint Biocides.” Biofouling, 26 73 (2010)

Schultz, MP, Bendick, JA, Holm, ER, Hertel, WM, “Economic Impact of Biofouling on a Naval Surface Ship.” Biofouling, 27 87 (2011)

Carteau, David, Vallée-Réhel, Karine, et al., “Development of Environmentally Friendly Antifouling Paints Using Biodegradable Polymer and Lower Toxic Substances.” Prog. Org. Coat., 77 (2) 485–493 (2014)

Briassoulis, D, “An Overview on the Mechanical Behaviour of Biodegradable Agricultural Films.” J. Polym. Environ., 12 (2) 65–81 (2004)

Cohn, D, Salomon, AH, “Designing Biodegradable Multiblock PCL/PLA Thermoplastic Elastomers.” Biomaterials, 26 (15) 2297–2305 (2005)

Ma, C, Xu, L, Xu, W, et al., “Degradable Polyurethane for Marine Anti-biofouling.” J. Mater. Chem. B, 1 (24) 3099–3106 (2013)

Beigbeder, A, Degee, P, Conlan, SL, Mutton, RJ, Clare, AS, Pettitt, ME, Callow, ME, Callow, JA, Dubois, P, “Preparation and Characterisation of Silicone-Based Coatings Filled with Carbon Nanotubes and Natural Sepiolite and Their Application as Marine Fouling-Release Coatings.” Biofouling, 24 291 (2008)

Magin, CM, Long, CJ, Cooper, SP, Ista, LK, Lopez, GP, Brennan, AB, “Engineered Antifouling Microtopographies: The Role of Reynolds Number in a Model that Predicts Attachment of Zoospores of Ulva and Cells of Cobetia Marina.” Biofouling, 26 719 (2010)

Li, Jiang, Wang, Guoqing, Ding, Chunhua, Jiang, Hong, Wang, Peiqing, “Synthesis and Evaluation of Polystyrene–Polybutadiene–Polystyrene–Dodecafluoroheptyl Methacrylate/Polystyrene–Polybutadiene–Polystyrene Hybrid Antifouling Coating.” J. Colloid Interface Sci., 434 (10) 71–76 (2014)

Youngblood, JP, Andruzzi, L, Ober, CK, et al., “Coatings Based on Side-Chain Ether-Linked Poly(Ethylene Glycol) and Fluorocarbon Polymers for the Control of Marine Biofouling.” Biofouling, 19 91–98 (2003)

Li, Jiang, Xie, Zhuolin, Wang, Guoqing, Ding, Chunhua, Jiang, Hong, Wang, Peiqing, “Preparation and Evaluation of Amphiphilic Polymer as Fouling-Release Coating in Marine Environment.” J. Coat. Technol. Res., 10 1–9 (2017)

Weinman, Craig J, Finlay, John A, Park, Daewon, et al., “ABC Triblock Surface Active Block Copolymer with Grafted Ethoxylated Fluoroalkyl Amphiphilic Side Chains for Marine Antifouling/Fouling-Release Applications.” Langmuir, 25 (20) 12266–12274 (2009)

Schumacher, JF, Carman, ML, Estes, TG, et al., “Engineered Antifouling Microtopographies—Effect of Feature Size, Geometry, and Roughness on Settlement of Zoospores of the Green Alga Ulva.” Biofouling, 23 (1) 55–62 (2007)

Yebra, DM, Kiil, S, Dam-Johansen, K, “Antifouling Technology—Past, Present and Future Steps Towards Efficient and Environmentally Friendly Antifouling Coatings.” Prog. Org. Coat., 50 75–104 (2004)

Acknowledgments

The authors are grateful for the financial supports of the horizontal projects (zzzz002023317 and zzzz002023301). This study was also supported by the Analysis and Testing Center of Hainan University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Xu, Y., Wang, G., Xie, Z. et al. Preparation and evaluation of degradable polyurethane with low surface energy for marine antifouling coating. J Coat Technol Res 16, 1055–1064 (2019). https://doi.org/10.1007/s11998-018-00180-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-018-00180-4