Abstract

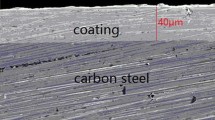

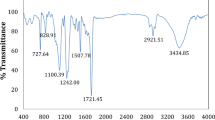

Micas/polypyrroles (PPys) doped with molybdate, p-toluene sulfonate, dodecyl benzene sulfonate, and 2-naphthalene sulfonate composite pigments were synthesized by chemical oxidative polymerization and characterized in coatings for corrosion protection on cold rolled steel substrate by various electrochemical techniques. Synthesized composite pigments were characterized for morphology by scanning electron microscopy, which indicated physical formation of PPy on the surface of mica. Chemical composition of the composite pigments was analyzed by X-ray photoelectron spectroscopy which chemically confirmed doped PPy formation on the mica surface. Coatings were formulated at 20% pigment volume concentration (composite pigments or as-received mica pigment) and were applied on cold rolled steel substrate. Coatings were exposed to salt spray test conditions (ASTM B117) for 30 days and were periodically assessed for corrosion with electrochemical impedance spectroscopy (EIS), open circuit potential (OCP), and potentiodynamic polarization. EIS and circuit modeling results demonstrated higher coating resistance (R c) for mica/PPy (doped) composite coatings as compared to as-received mica pigment containing coating after 30 days of salt spray exposure. Lower current density and more positive corrosion potential values were observed for mica/PPy (doped) composite coatings as compared to mica pigment-based coating in potentiodynamic polarization measurements, indicating improved corrosion protection for cold rolled steel substrate. OCP measurements revealed more positive values for mica/PPy (doped) composite coatings as compared to mica pigment-based coating suggesting superior corrosion protection for mica/PPy (doped) composites.

Similar content being viewed by others

References

DeBerry, DW, “Modification of the Electrochemical and Corrosion Behavior of Stainless Steels with an Electroactive Coating.” J. Electrochem. Soc., 132 (5) 1022–1026 (1985)

Stenger-Smith, JD, “Intrinsically Electrically Conducting Polymers. Synthesis, Characterization, and Their Applications.” Prog. Polym. Sci., 23 (1) 57–79 (1998)

Deshpande, P, Jadhav, N, Gelling, V, Sazou, D, “Conducting Polymers for Corrosion Protection: A Review.” J. Coat. Technol. Res., 11 (4) 473–494 (2014)

Jadhav, N, Jensen, M, Gelling, V, “Tungstate and Vanadate-Doped Polypyrrole/Aluminum Flake Composite Coatings for the Corrosion Protection of Aluminum 2024-T3.” J. Coat. Technol. Res., 12 (2) 259–276 (2015)

Castagno, KRL, Dalmoro, V, Azambuja, DS, “Characterization and Corrosion of Polypyrrole/Sodium Dodecylbenzene Sulfonate Electropolymerised on Aluminum Alloy 1100.” Mater. Chem. Phys., 130 (1–2) 721–726 (2011)

Jadhav, N, Vetter, CA, Gelling, VJ, “The Effect of Polymer Morphology on the Performance of a Corrosion Inhibiting Polypyrrole/Aluminum Flake Composite Pigment.” Electrochim. Acta, 102 28–43 (2013)

He, J, Gelling, VJ, Tallman, DE, Bierwagen, GP, Wallace, GG, “Conducting Polymers and Corrosion III. A Scanning Vibrating Electrode Study of Poly(3-Octyl Pyrrole) on Steel and Aluminum.” J. Electrochem. Soc., 147 (10) 3667–3672 (2000)

Sabouri, M, Shahrabi, T, Faridi, HR, Salasi, M, “Influence of Phosphate Ion Dopant on Corrosion Protection Properties of Polypyrrole Coatings on Carbon Steel.” Corros. Eng. Sci. Technol., 44 (1) 51–56 (2009)

Jadhav, N, Vetter, CA, Gelling, VJ, “Characterization and Electrochemical Investigations of Polypyrrole/Aluminum Flake Composite Pigments on AA 2024-T3 Substrate.” ECS Trans., 41 (15) 75–89 (2012)

Jensen, MB, Peterson, MJ, Jadhav, N, Gelling, VJ, “SECM Investigation of Corrosion Inhibition by Tungstate- and Vanadate-Doped Polypyrrole/Aluminum Flake Composite Coatings on AA2024-T3.” Prog. Org. Coat., 77 (12, Part B) 2116–2122 (2014)

Jadhav, N, Gelling, V, “Titanium Dioxide/Conducting Polymers Composite Pigments for Corrosion Protection of Cold Rolled Steel.” J. Coat. Technol. Res., 12 (1) 137–152 (2015)

Jadhav, N, Gelling, VJ, “Synthesis and Characterization of Micaceous Iron Oxide/Polypyrrole Composite Pigments and Their Application for Corrosion Protection of Cold-Rolled Steel.” Corrosion, 70 (5) 464–474 (2013)

Sabouri, M, Shahrabi, T, Hosseini, MG, “Improving Corrosion Protection Performance of Polypyrrole Coating by Tungstate Ion Dopants.” Russ. J. Electrochem., 43 (12) 1390–1397 (2007)

Hosseini, MG, Sabouri, M, Shahrabi, T, “Comparison of the Corrosion Protection of Mild Steel by Polypyrrole–Phosphate and Polypyrrole–Tungstenate Coatings.” J. Appl. Polym. Sci., 110 (5) 2733–2741 (2008)

Zor, S, Kandemirli, F, Yakar, E, Arslan, T, “Electrochemical Synthesis of Polypyrrole on Aluminium in Different Anions and Corrosion Protection of Aluminium.” Prot. Metals Phys. Chem. Surf., 46 (1) 110–116 (2010)

Jayamurgan, P, Ponnuswamy, V, Ashokan, S, Mahalingam, T, “The Effect of Dopant on Structural, Thermal and Morphological Properties of DBSA-Doped Polypyrrole.” Iran. Polym. J., 22 (3) 219–225 (2013)

Kim, DK, Oh, KW, Ahn, HJ, Kim, SH, “Synthesis and Characterization of Polypyrrole Rod Doped with p-Toluenesulfonic Acid Via Micelle Formation.” J. Appl. Polym. Sci., 107 (6) 3925–3932 (2008)

Ding, C, Qian, X, Yu, G, An, X, “Dopant Effect and Characterization of Polypyrrole-Cellulose Composites Prepared by In Situ Polymerization Process.” Cellulose, 17 (6) 1067–1077 (2010)

Prissanaroon, W, Brack, N, Pigram, PJ, Liesegang, J, Cardwell, TJ, “Surface and Electrochemical Study of DBSA-Doped Polypyrrole Films Grown on Stainless Steel.” Surf. Interface Anal., 33 (8) 653–662 (2002)

Shreepathi, S, Bajaj, P, Mallik, BP, “Electrochemical Impedance Spectroscopy Investigations of Epoxy Zinc Rich Coatings: Role of Zn Content On Corrosion Protection Mechanism.” Electrochim. Acta, 55 (18) 5129–5134 (2010)

Upadhyay, V, Harkal, UD, Webster, DC, Bierwagen, GP, “Preliminary Investigation of the Impact of Polymer Composition on Electrochemical Properties of Coatings as Determined by Electrochemical Impedance Spectroscopy.” J. Coat. Technol. Res., 10 (6) 865–878 (2013)

Allahar, KN, Upadhyay, V, Bierwagen, GP, Gelling, VJ, “Monitoring of a Military Vehicle Coating Under Prohesion Exposure by Embedded Sensors.” Prog. Org. Coat., 65 (1) 142–151 (2009)

Nguyen Thi Le, H, Garcia, B, Deslouis, C, Le Xuan, Q, “Corrosion Protection of Iron by Polystyrenesulfonate-Doped Polypyrrole Films.” J. Appl. Electrochem., 32 (1) 105–110 (2002)

Qi, K, Qiu, Y, Chen, Z, Guo, X, “Corrosion of Conductive Polypyrrole: Effects of Environmental Factors, Electrochemical Stimulation, and Doping Anions.” Corros. Sci., 60 50–58 (2012)

Rammelt, U, Duc, LM, Plieth, W, “Improvement of Protection Performance of Polypyrrole by Dopant Anions.” J. Appl. Electrochem., 35 (12) 1225–1230 (2005)

Ohtsuka, T, Iida, M, Ueda, M, “Polypyrrole Coating Doped by Molybdo-Phosphate Anions for Corrosion Prevention of Carbon Steels.” J. Solid State Electrochem., 10 (9) 714–720 (2006)

Acknowledgments

The authors gratefully acknowledge the support of this research by US Army Research Laboratory under Grant Nos. W911NF-09-2-0014, W911NF-10-2-0082, and W911NF-11-2-0027.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Jadhav, N., Matsuda, T. & Gelling, V. Mica/polypyrrole (doped) composite containing coatings for the corrosion protection of cold rolled steel. J Coat Technol Res 15, 363–374 (2018). https://doi.org/10.1007/s11998-017-9974-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-017-9974-x