Abstract

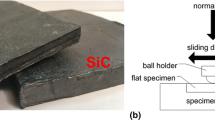

In this article, the phenomenon of erosion by solid particles on the silicon carbide coating (SiC) deposited on AISI 304 stainless steel substrates was analyzed. The specimens used were 25 mm square and 3 mm thick, using 300–450 μm silicon carbide as abrasive particles. Experimental tests were performed on an apparatus developed in accordance with some parameters of the ASTM G76-95 standard. Four angles of impact at 30°, 45°, 60°, and 90° are contemplated with an approximate particle velocity of 25 ± 2 m/s with a maximum exposure time of 10 min per specimen, taking measurements of weight intervals every 2 min to determine the mass loss. The wear mechanisms that were identified to small angles were: plastic deformation, displacement of material, and plow mechanisms. While at higher impact angles, the mechanisms were mainly: cutting, pitting, fractures, and cracks. It was observed that the rate of erosion depends on the angle of incidence of the abrasive particles. The results indicated that a higher damage zone was obtained at 30° of impact angle; on the other hand, at an angle of 90° there was less damage.

Similar content being viewed by others

References

Buckley, DH, Surface Effects in Adhesion, Friction, Wear, and Lubrication, Tribology Series. Elsevier, Amsterdam

Rossnagel, SM, Cuomo, JJ, Westwood, WD (eds), “Handbook of Plasma Processing Technology, Cap 2.” Noyes Publications, New Jersey, 1990

Baldenebro Castillo, RE, Master’s thesis in Engineering, “Estudio y análisis del fenómeno de la erosión sólida en diferentes materiales metálicos empleados en la manufactura”. IPN-SEPI ESIME–UZ, México, D. F., 2011

Pierson, HO, Handbook of Chemical Vapor Deposition (CVD)” Principles, Technology, and Applications. William Andrew Publishing, LLC, Norwich (1999)

Davis, JR, Alloy Digest Sourcebook: Stainless Steels. ASM International, Geauga County, 2000

Lasorsa, C, Pineda Ramos, P, Volosín, JI, Recubrimiento duro de carburo de silicio sobre substratos metálicos y de silicio aplicados mediante la técnica de plasma CVD, 11 Congreso Binacional de Metalurgia y Materiales. SAM/CONAMET, Rosario, Argentina, 2011

Lieberman, M, Lichtenberg, A, Principles of Plasma Discharges and Materials Processing. Wiley, New York (1994)

Bunshah, R-F, et al (eds), Deposition Technologies for Films and Coatings, Cap. 2. Noyes Publications, New Jersey, 1982

Schuegraf, K (eds), “Handbook of Thin-Films Deposition Processes and Techniques, Cap 9.” Noyes Publications, New Jersey, 1988

Martínez Arriero, Z, Master’s thesis in Engineering, “Análisis del desgaste por erosión por impacto de partículas sólidas en recubrimientos de Carburo de Silicio (SiC) y Carbono Tipo Diamante (DLC) sobre sustratos de acero inoxidable”. IPN-SEPI ESIME–UZ, México, D. F., 2015

G76.-95. (Standard ASTM, Standard Test Method for Conducting Erosion Tests by Solid Particle Impingement, 2000)

C1624-05. (Standard ASTM, Standard Test Method for Adhesion Strength and Mechanical Failure Modes of Ceramic Coatings by Quantitative Single Point Scratch Testing, 2015)

Sedano-de la Rosa, C, Vite-Torres, M, Gallardo-Hernández, EA, Laguna-Camacho, JR, Godínez-Salcedo, JG, Farfán-Cabrera, LI, “Effect of Tangential Velocity on Erosion of ASTM A-106 Grade B Steel Pipe Under Turbulent Swirling Impinging Jet.” Tribol. Int., (2017). doi:10.1016/j.triboin.2017.01.011

Finnie, I, Stevik, GR, Ridgely, JR, “The Influence of Impingement Angle on the Erosion of Ductile Metals by Angular Abrasive Particles.” Wear, 152 (1) 91–98 (1992)

Acknowledgments

The authors wish to thank Dr. Carlos A. Lasorsa and M. C. Pedro Pineda Ramos of the National Technological University, Regional Faculty Haedo, Buenos Aires, Argentina, for their invaluable support for hard DLC and SiC coatings and also Dr. Elizabeth Garfias Garcia and Dr. Isaias Hilerio of UAM Azcapotzalco, for their support with scanning electron microscope sessions. Funding was provided by IPN-SIP.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vite-Torres, M., Martínez-Arriero, Z., Gallardo-Hernández, E.A. et al. Performance of the silicon carbide coating under erosion wear by erosion by solid particles. J Coat Technol Res 14, 863–868 (2017). https://doi.org/10.1007/s11998-017-9950-5

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-017-9950-5