Abstract

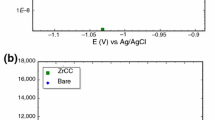

In this study, the effect of phosphate ion (PO4 3−) was investigated on the different properties of a zirconium-based nanoceramic conversion layer. At the first step, the phosphate ion concentration was optimized using the DC polarization technique. In the next step, the surface morphological aspect of the bare and treated mild steel was evaluated utilizing field emission scanning electron microscopy technique. The results indicate formation of a composite conversion coating on the mild steel surface. Practical adhesion strength between treated mild steels and an epoxy resin was studied by pull-off adhesion test. Finally, the effect of phosphate ion on the corrosion properties of epoxy-coated mild steel was evaluated utilizing electrochemical impedance spectroscopy. It was revealed that the phosphate ion could increase both the adhesion strength and anticorrosion properties of the epoxy-coated substrate.

Similar content being viewed by others

References

Schweitzer, PA, Corrosion Engineering Handbook. CRC Press, Boca Raton, 2006

Forsgren, A, Corrosion Control Through Organic Coatings. CRC Press, Boca Raton, 2006

Zhou, W, Jeffers, TE, “Application Temperature, Cure, and Film Thickness Affect Cathodic Disboniment of FBE Coatings.” Mater. Perf., 45 24 (2006)

Grundmeier, G, Stratmann, M, “Adhesion and De-adhesion Mechanisms at Polymer/Metal Interfaces: Mechanistic Understanding Based on In Situ Studies of Buried Interfaces.” Annu. Rev. Mater. Res., 35 571 (2005)

Cho, KW, Rao, VS, Kwon, H, “Microstructure and Electrochemical Characterization of Trivalent Chromium Based Conversion Coating on Zinc.” Electrochim. Acta, 52 4449–4454 (2007)

Chen, WK, Bai, CY, Liu, CM, Lin, CS, Ger, MD, “The Effect of Chromic Sulfate Concentration and Immersion Time on the Structures and Anticorrosive Performance of the Cr(III) Conversion Coatings on Aluminum Alloys.” Appl. Surf. Sci., 256 4924–4930 (2010)

Agency for Toxic Substance, Toxicological Profile for Chromium, ATDSRyTP-88y10. U.S. Public Health Service, Washington, DC, 1989

Ramezanzadeh, B, Attar, MM, Farzam, M, “Corrosion Performance of a Hot-Dip Galvanized Steel Treated by Different Kinds of Conversion Coatings.” Surf. Coat. Technol., 205 874 (2010)

Verdier, S, Delalande, S, van der Laak, N, Metson, J, Dalard, F, “Monochromatized X-ray Photoelectron Spectroscopy of the AM60 Magnesium Alloy Surface After Treatments in Fluoride Based Ti and Zr Solutions.” Surf. Interface Anal., 37 509–516 (2005)

Fedrizzi, L, Rodriguez, FJ, Rossi, S, Deflorian, F, Di Maggio, R, “The Use of Electrochemical Techniques to Study the Corrosion Behaviour of Organic Coatings on Steel Pretreated with Sol–Gel Zirconia Films.” Electrochim. Acta, 46 3715–3724 (2001)

Adhikari, S, Unocic, KA, Zhaia, Y, Frankel, GS, Zimmerman, J, Frista, W, “Hexafluorozirconic Acid Based Surface Pretreatments: Characterization and Performance Assessment.” Electrochim. Acta, 56 1912–1924 (2011)

Ghanbari, A, Attar, MM, “Surface Free Energy Characterization and Adhesion Performance of Mild Steel Treated Based on Zirconium Conversion Coating: A Comparative Study.” Sur. Coat. Technol., 246 26–33 (2014)

Maggio, R, Fedrizzi, L, Rossi, S, “Effect of the Chemical Modification of the Precursor of ZrO2 Films on the Adhesion of Organic Coatings.” J. Adhes. Sci. Technol., 15 79–808 (2001)

Ghanbari, A, Attar, MM, “The Effect of Zirconium-Based Surface Treatment on the Cathodic Disbonding Resistance of Epoxy Coated Mild Steel.” App. Surf. Sci., 316 429–434 (2014)

Puomi, P, Fagerholm, HM, Rosenholm, JB, Jyrkäs, K, “Comparison of Different Commercial Pretreatment Methods for Hot-Dip Galvanized and Galfan Coated Steel.” Surf. Coat. Technol., 115 70–78 (1999)

Niknahad, M, Moradian, S, Mirabedini, SM, “The Adhesion Properties and Corrosion Performance of Differently Pretreated Epoxy Coatings on an Aluminum Alloy.” Corros. Sci., 52 1948–1957 (2010)

Mirabedini, SM, Scantlebury, JD, Thompson, GE, Moradian, S, “Adhesive Strength of Powder Coated Aluminum Substrates.” Int. J. Adhes. Adhes., 25 484–494 (2005)

Mohammad Hosseini, R, Sarabi, AA, Mohammadloo, HE, Sarayloo, M, “The Performance Improvement of Zr Conversion Coating Through Mn Incorporation: With and Without Organic Coating.” Surf. Coat. Technol., 258 437–446 (2014)

Andreatta, F, Lanzutti, A, Paussa, L, Fedrizzi, L, “Addition of Phosphates or Copper Nitrate in a Fluotitanate Conversion Coating Containing a Silane Coupling Agent for Aluminium Alloy AA6014.” Prog. Org. Coat., 77 2107–2115 (2014)

Kendig, M, Scantlebury, D, Fifth International Symposium on Advances in Corrosion Protection by Organic Coating, The Electrochemical Society, Mexico, 2010.

Kendig, M, Leidheiser, H, “The Electrical Properties of Protective Polymer Coatings as Related to Corrosion of the Substrate.” J. Electrochem. Soc., 123 982 (1976)

Deflorian, F, Ferizzi, L, Borona, PL, Electrochemical Approach to Selected Corrosion and Corrosion Control Studies, European Federation of Corrosion Publication No. 28, IOM Communications Ltd, London, 2000

van der Weijde, DH, van Westing, EPM, de Wit, JHW, “EIS Measurements on Artificial Blisters in Organic Coatings.” Electrochim. Acta, 41 1103 (1996)

Shao, Y, Jia, C, Meng, G, Zhang, T, Wang, F, “The Role of a Zinc Phosphate Pigment in the Corrosion of Scratched Epoxy-Coated Steel.” Corros. Sci., 51 371–379 (2009)

Huang, Y, Shih, H, Huang, H, Daugherty, J, Wu, S, Ramanathan, S, Chang, C, Mansfeld, F, “Evaluation of the Corrosion Resistance of Anodized Aluminum 6061 Using Electrochemical Impedance Spectroscopy (EIS).” Corros. Sci., 50 3569–3575 (2008)

Ghanbari, A, Reza, M, Attar, M, “Corrosion Behavior of Zirconium Treated Mild Steel With and Without Organic Coating: A Comparative Study.” Surf. Rev. Lett., 21 (6) 1450088 (2014)

Mohammadloo, HE, Sarabi, AA, Sabbagh Alvani, AA, Salimi, R, Sameie, H, “The Effect of Solution Temperature and pH on Corrosion Performance and Morphology of Nanoceramic-Based Conversion Thin Film.” Mater. Corros., 64 (6) 535–543 (2013)

Mohammadloo, HE, Sarabi, AA, Alvani, AAS, Sameie, H, Salimi, R, “Nano-ceramic Hexafluorozirconic Acid Based Conversion Thin Film: Surface Characterization and Electrochemical Study.” Surf. Coat. Technol., 206 4132–4139 (2012)

Taheri, P, Lill, K, de Wit, JHW, Mol, JMC, Terryn, H, “Effects of Zinc Surface Acid-Based Properties on Formation Mechanisms and Interfacial Bonding Properties of Zirconium-Based Conversion Layers.” J. Phys. Chem. C, 116 8426–8436 (2012)

Mafi, R, Mirabedini, SM, Naderi, R, Attar, MM, “Effect of Curing Characterization on the Corrosion Performance of Polyester and Polyester/Epoxy Powder Coatings.” Corros. Sci., 50 3280–3286 (2008)

Niknahad, M, Moradian, S, Mirabedini, SM, “The Adhesion Properties and Corrosion Performance of Differently Pretreated Epoxy Coatings on an Aluminium Alloy.” Corros. Sci., 52 1348–1357 (2010)

Schem, M, Schmidt, T, Gerwann, J, Wittmar, M, Veith, M, Thompson, GE, Molchan, IS, Hashimoto, T, Skeldon, P, Phani, AR, Santucci, S, Zheludkevich, ML, “CeO2-Filled Sol–Gel Coatings for Corrosion Protection of AA2024-T3 Aluminium Alloy.” Corros. Sci., 51 2304–2315 (2009)

Kendig, M, Mansfeld, F, Tsai, S, “Determination of the Long Term Corrosion Behavior of Coated Steel with A.C. Impedance Measurements.” Corros. Sci., 23 317–329 (1983)

Brasher, DM, Kingsbury, AH, “Electrical Measurements in the Study of Immersed Paint Coatings on Metal. I. Comparison Between Capacitance and Gravimetric Methods of Estimating Water Uptake.” J. Appl. Chem., 4 62–72 (1954)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ghanbari, A., Attar, M.M. Influence of phosphate ion on the morphology, adhesion strength, and corrosion performance of zirconium-based surface treatment. J Coat Technol Res (2015). https://doi.org/10.1007/s11998-015-9694-z

Published:

DOI: https://doi.org/10.1007/s11998-015-9694-z