Abstract

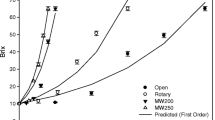

Clarified guava juice was concentrated using ohmic heating-assisted vacuum evaporation (OHVE) and compared the process with rotary vacuum evaporation (VE). Laboratory-scale OHVE system with condensing unit and data logging system was developed to accomplish this task. Process parameters such as temperature (50–70 °C), holding time (40–120 min), voltage gradient (9–15 V/cm), and vacuum pressure (400–600 mmHg) were optimized based on the total soluble solids of concentrated guava fruit juice using response surface methodology. Guava fruit juice concentrate was produced by OHVE and VE at the optimum process conditions and evaluated for quality parameters, namely, pH, density, ascorbic acid (AA), non-enzymatic browning index (NEBI), titratable acidity (TA), viscosity, and chromatic properties (L*, a*, b*, ΔE, hue angle, and chroma). The quality parameters determined from the OHVE on various quality attributes at optimized process parameters (voltage gradient 14.95 V/cm and vacuum 550 mmHg (gauge)) and at different temperatures (50–70 °C), and process times (0–120 min) were in the range of pH: 3.434 to 3.934, density: 969 to 1286 kg/m3, AA: 0.239 mg/100 mL, NEBI: 0.071 to 1.665 OD420 nm, TA: 0.38% to 1.81%, viscosity: 3.6 to 25.83 cP, L*: 90.00 to 22.6, a*: 2.36 to 9.79, b*: 4.05 to 29.04, hue angle: 108.64° to 120.89° and chroma: 4.72 to 30.65. The obtained results ascertain the better-quality retention in juice processed through combining the ohmic heating with vacuum compared with conventional evaporation method of rotary vacuum evaporation (RVE).

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Abedelmaksoud, T. G., Mohsen, S. M., Duedahl-Olesen, L., Elnikeety, M. M., & Feyissa, A. H. (2018). Optimization of ohmic heating parameters for polyphenoloxidase inactivation in not-from-concentrate elstar apple juice using RSM. Journal of Food Science and Technology, 55(7), 2420–2428. https://doi.org/10.1007/s13197-018-3159-1

Adnan, A., Mushtaq, M., & ul Islam, T. (2018). Fruit juice concentrates. In G. Rajuria & B. K. Tiwari (Eds.), Fruit juices - extraction, composition, quality and analysis. London: Academic Press. https://doi.org/10.1016/B978-0-12-802230-6.00012-6

Akesowan, A., & Choonhahirun, A. (2013). Effect of enzyme treatment on guava juice production using response surface methodology. Journal of Animal and Plant Sciences, 23(1), 114–120.

Alkanan, Z. T., Altemimi, A. B., Al-Hilphy, A. R., Watson, D. G., & Pratap-Singh, A. (2021a). Ohmic heating in the food industry: Developments in concepts and applications during 2013–2020. Applied Sciences, 11(6), 2507. https://doi.org/10.3390/app11062507

Alkanan, Z. T., Altemimi, A. B., Al-Hilphy, A. R. S., Cacciola, F., & Ibrahim, S. A. (2021b). Application and effects of ohmic-vacuum combination heating on the quality factors of tomato paste. Foods, 10, 2920. https://doi.org/10.3390/foods10122920

AOAC. (2016). Official methods of analysis. Washington, DC, USA: Association of Official Analytical Chemists.

Ashitha, G. N., Prince, M. V., & Sudheer, K. P. (2020). Mild thermal processing of cashew apple juice using ohmic heating. Journal of Tropical Agriculture, 58(1), 44–52.

Assawarachan, R., & Noomhorm, A. (2011). Mathematical models for vacuum to microwave concentration behavior of pineapple juice. Journal of Food Process Engineering, 34(5), 1485–1505. https://doi.org/10.1111/j.1745-4530.2009.00536.x

Assiry, A. M., Sastry, S. K., & Samaranayake, C. (2003). Degradation kinetics of ascorbic acid during ohmic heating with stainless steel electrodes. Journal of Applied Electrochemistry, 33(2), 187–196. https://doi.org/10.1023/A:1024076721332

Bender, D., Gratz, M., Vogt, S., Fauster, T., Wicki, B., Pichler, S., Kinner, M., Jäger, H., & Schoenlechner, R. (2019). Ohmic heating - A novel approach for gluten-free bread baking. Food and Bioprocess Technology, 12(9), 1603–1613. https://doi.org/10.1007/s11947-019-02324-9

Bozkir, H., & Baysal, T. (2017). Concentration of apple juice using a vacuum microwave evaporator as a novel technique: Determination of quality characteristics. Journal of Food Process Engineering, 40(5), e12535. https://doi.org/10.1111/jfpe.12535

Brasil, I. M., Maia, G. A., & Figuiredo, R. W. (1995). Physical-chemical changes during extraction and clarification of guava juice. Food Chemistry, 54, 383–386. https://doi.org/10.1016/0308-8146(95)00066-R

Boldaji, M. T., Borghei, A. M., Beheshti, B., & Hosseini, S. E. (2015). The process of producing tomato paste by ohmic heating method. Journal of Food Science and Technology, 52(6), 3598–3606. https://doi.org/10.1007/s13197-014-1424-5

Cabas, B. M., & Icier, F. (2021). Ohmic heating-assisted extraction of natural color matters from red beetroot. Food and Bioprocess Technology, 14(11), 2062–2077. https://doi.org/10.1007/s11947-021-02698-9

Cassano, A., Conidi, C., Timpone, R., D’avella, M., & Drioli, E. (2007). A membrane-based process for the clarification and the concentration of the cactus pear juice. Journal of Food Engineering, 80(3), 914–921. https://doi.org/10.1016/j.jfoodeng.2006.08.005

Chakraborty, I., & Athmaselvi, K. A. (2014). Changes in physicochemical properties of guava juice during ohmic heating. Journal of Ready to Eat Food, 1(4), 152–157.

Chopda, C. A., & Barrett, D. M. (2001). Optimization of guava juice and powder production. Journal of Food Processing and Preservation, 25, 411–430. https://doi.org/10.1111/j.1745-4549.2001.tb00470.x

Çilingir, S., Goksu, A., & Sabanci, S. (2021). Production of pectin from lemon peel powder using ohmic heating-assisted extraction process. Food and Bioprocess Technology, 14(7), 1349–1360. https://doi.org/10.1007/s11947-021-02636-9

Cokgezme, O. F., Sabanci, S., Cevik, M., Yildiz, H., & Icier, F. (2017). Performance analyses for evaporation of pomegranate juice in ohmic heating assisted vacuum system. Journal of Food Engineering, 207, 1–9. https://doi.org/10.1016/j.jfoodeng.2017.03.015

Darvishi, H., Khostaghaza, M. H., & Najafi, G. (2013). Ohmic heating of pomegranate juice: Electrical conductivity and pH change. Journal of the Saudi Society of Agricultural Sciences, 12, 101–108. https://doi.org/10.1016/j.jssas.2012.08.003

Darvishi, H., Mohammadi, P., Fadavi, A., Koushesh Saba, M., & Behroozi-Khazaei, N. (2019). Quality preservation of orange concentrate by using hybrid ohmic-vacuum heating. Food Chemistry, 289, 292–298. https://doi.org/10.1016/j.foodchem.2019.03.043

Darvishi, H., Koushesh Saba, M., Behroozi-Khazaei, N., & Nourbakhsh, H. (2020). Improving quality and quantity attributes of grape juice concentrate (molasses) using ohmic heating. Journal of Food Science and Technology, 57(4), 1362–1370. https://doi.org/10.1007/s13197-019-04170-1

Demirdöven, A., & Baysal, T. (2014). Optimization of ohmic heating applications for pectin methylesterase inactivation in orange juice. Journal of Food Science and Technology, 51(9), 1817–1826. https://doi.org/10.1007/s13197-012-0700-5

Department of Agriculture and Farmers Welfare. (2022). Area and production of horticulture crops: All India. Retrieved July 29, 2022, from https://agricoop.nic.in/sites

Dewanti-Hariyadi, R. (2013). Microbiological quality and safety of fruit juices. Foodreview International, 1(1), 54–57.

Fadavi, A., & Salari, S. (2019). Ohmic heating of lemon and grapefruit juices under vacuum pressure-comparison of electrical conductivity and heating rate. Journal of Food Science, 84(10), 2868–2875. https://doi.org/10.1111/1750-3841.14802

Fadavi, A., Salari, S., Mansouri, A., & Hoseini, S. (2020). Effects of vacuum and juice concentration on electrical conductivity by the ohmic method: A case study of sour cherry. Food and Bioprocess Technology, 13(7), 1146–1153. https://doi.org/10.1007/s11947-020-02463-4

Fadavi, A., Yousefi, S., Darvishi, H., & Mirsaeedghazi, H. (2018). Comparative study of ohmic vacuum, ohmic, and conventional-vacuum heating methods on the quality of tomato concentrate. Innovative Food Science & Emerging Technologies, 47, 225–230. https://doi.org/10.1016/j.ifset.2018.03.004

FAO. (2021). Major tropical fruits: market review 2020. Rome, Italy: Food and Agriculture Organization of the United Nations.

Funcia, E. S., Gut, J. A. W., & Sastry, S. K. (2020). Effect of electric field on pectinesterase inactivation during orange juice pasteurization by ohmic heating. Food and Bioprocess Technology, 13(7), 1206–1214. https://doi.org/10.1007/s11947-020-02478-x

Geankoplis, C. J., Hersel, A. A., & Lepek, D. H. (2018). Transport processes and separation process principles (4th ed.). Boston, MA, USA: Prentice-Hall Inc.

Hwang, J. H., Jung, A. H., & Park, S. H. (2022). Efficacy of ohmic vacuum concentration for orange juice concentrates and their physicochemical properties under different voltage gradients. LWT-Food Science and Technology, 154, 112750. https://doi.org/10.1016/j.lwt.2021.112750

Icier, F., Yildiz, H., Sabanci, S., Cevik, M., & Cokgezme, O. F. (2017). Ohmic heating assisted vacuum evaporation of pomegranate juice: Electrical conductivity changes. Innovative Food Science & Emerging Technologies, 39, 241–246. https://doi.org/10.1016/j.ifset.2016.12.014

Kaur, S., Sarkar, B. C., Sharma, H. K., & Singh, C. (2009). Optimization of enzymatic hydrolysis pretreatment conditions for enhanced juice recovery from guava fruit using response surface methodology. Food and Bioprocess Technology, 2(1), 96–100. https://doi.org/10.1007/s11947-008-0119-1

Kim, S. S., Park, S. H., Kim, S. H., & Kang, D. H. (2019). Synergistic effect of ohmic heating and UV-C irradiation for inactivation of Escherichia coli O157: H7, Salmonella typhimurium and Listeria monocytogenes in buffered peptone water and tomato juice. Food Control, 102, 69–75. https://doi.org/10.1016/j.foodcont.2019.03.011

Kumar, R., & Singh, A. K. (2019). Clarification of guava (Psidium guajava) fruit juice using multi-enzyme (pectinase, cellulase and hemicellulase) treatment: Optimization of processing parameters. International Journal of Innovative Technology and Exploring Engineering, 8(12), 5266–5279.

Lee, S. Y., Sagong, H. G., Ryu, S., & Kang, D. H. (2012). Effect of continuous ohmic heating to inactivate Escherichia coli O157:H7, Salmonella typhimurium and Listeria monocytogenes in orange juice and tomato juice. Journal of Applied Microbiology, 112, 723–731. https://doi.org/10.1111/j.1365-2672.2012.05247.x

Leizerson, S., & Shimoni, E. (2005). Stability and sensory shelf life of orange juice pasteurized by continuous ohmic heating. Journal of Agricultural and Food Chemistry, 53(10), 4012–4018. https://doi.org/10.1021/jf047857q

Li., Xu, X., Wang, L., & Regenstein, J.M. (2019). Effect of ohmic heating on physicochemical properties and the key enzymes of water chestnut juice. Journal of Food Processing and Preservation, 43, e13919. https://doi.org/10.1111/jfpp.13919

Magerramov, M. A., Abdulagatov, A. I., Abdulagatov, I. M., & Azizov, N. D. (2008). Pressure and temperature dependent density change of juices during concentration. Food Bioprocess Technology, 1, 254–269. https://doi.org/10.1007/s11947-007-0022-1

Makroo, H. A., Saxena, J., Rastogi, N. K., & Srivastava, B. (2017a). Ohmic heating assisted polyphenol oxidase inactivation of watermelon juice: Effects of the treatment on pH, lycopene, total phenolic content, and color of the juice. Journal of Food Processing and Preservation, 41(6), e13271. https://doi.org/10.1111/jfpp.13271

Makroo, H. A., Rastogi, N. K., & Srivastava, B. (2017b). Enzyme inactivation of tomato juice by ohmic heating and its effects on physico-chemical characteristics of concentrated tomato paste. Journal of Food Process Engineering, 40(3), e12464. https://doi.org/10.1111/jfpe.12464

Maskan, M. (2006). Production of pomegranate (Punica granatum L.) juice concentrate by various heating methods: Color degradation and kinetics. Journal of Food Engineering, 72(3), 218–224. https://doi.org/10.1016/j.jfoodeng.2004.11.012

Meydav, S., Saguy, I., & Kopelman, I. J. (1977). Browning determination in citrus products. Journal of Agricultural and Food Chemistry, 25(3), 602–604. https://doi.org/10.1021/jf60211a030

Montgomery, D. C. (2017). Design and analysis of experiments. Hoboken, New Jersey: John Wiley & Sons.

Nizamani, S., Khaskheli, A. A., Jiskani, A. M., Khaskheli, S. A., Khaskheli, A. J., Poussio, G. B., Jamro, H., & Khaskheli, M. I. (2021). Isolation and identification of the fungi causing tomato fruit rot disease in the vicinity of Tandojam, Sindh. Agricultural Science Digest-A Research Journal, 41(Spl), 186–190. https://doi.org/10.18805/ag.D-269

Norouzi, S., Fadavi, A., & Darvishi, H. (2021). The ohmic and conventional heating methods in concentration of sour cherry juice: Quality and engineering factors. Journal of Food Engineering, 291, 110242. https://doi.org/10.1016/j.jfoodeng.2020.110242

Onsekizoglu, P., Bahceci, K. S., & Acar, M. J. (2010). Clarification and the concentration of apple juice using membrane processes: a comparative quality assessment. Journal of Membrane Science, 352(1–2), 160–165. https://doi.org/10.1016/j.memsci.2010.02.004

Park, I. K., Ha, J. W., & Kang, D. H. (2017). Investigation of optimum ohmic heating conditions for inactivation of Escherichia coli O157: H7, Salmonella enterica serovar Typhimurium, and Listeria monocytogenes in apple juice. BMC Microbiology, 17(1), 1–8. https://doi.org/10.1186/s12866-017-1029-z

Pino-Hernández, E., Pereira, R. N., Ballesteros, L. F., Vicente, A. A., Abrunhosa, L., & Teixeira, J. A. (2021). Effects of moderate electric fields on the post-harvest preservation of chestnuts. Food and Bioprocess Technology, 14(5), 920–934. https://doi.org/10.1007/s11947-021-02612-3

Sabanci, S., & Icier, F. (2017). Applicability of ohmic heating assisted vacuum evaporation for concentration of sour cherry juice. Journal of Food Engineering, 212, 262–270. https://doi.org/10.1016/j.jfoodeng.2017.06.004

Sabanci, S., Cevik, M., Cokgezme, O. F., Yildiz, H., & Icier, F. (2019). Quality characteristics of pomegranate juice concentrates produced by ohmic heating assisted vacuum evaporation. Journal of the Science of Food and Agriculture, 99(5), 2589–2595. https://doi.org/10.1002/jsfa.9474

Sabanci, S., & Icier, F. (2019). Effects of vacuum ohmic evaporation on some quality properties of sour cherry juice concentrates. International Journal of Food Engineering, 15(9), 20190055. https://doi.org/10.1515/ijfe-2019-0055

Sangpradab, J., Kamonpatana, P., Suwannaporn, P., & Huang, T. C. (2021). Ohmic heating-aided mechanical extraction of gamma-oryzanol and phytosterols in rice bran oil. Food and Bioprocess Technology, 14(8), 1542–1554. https://doi.org/10.1007/s11947-021-02655-6

Sastry, S. K. (2004). Advances in ohmic heating and moderate electric field (MEF) processing. In G. V. Barbosa-Canovas, M. S. Tapia, & M. P. Cano (Eds.), Novel Food Processing Technologies. Boca Raton, USA: CRC Press.

Saxena, J., Makroo, H. A., & Srivastava, B. (2016). Optimization of time-electric field combination for PPO inactivation in sugarcane juice by ohmic heating and its shelf life assessment. LWT-Food Science and Technology, 71, 329–338. https://doi.org/10.1016/j.lwt.2016.04.015

Shamsudin, R., Mohamed, I. O., & Yaman, N. K. M. (2005). Thermophysical properties of Thai seedless guava juice as affected by temperature and concentration. Journal of Food Engineering, 66(3), 395–399. https://doi.org/10.1016/j.jfoodeng.2004.04.007

Sin, H. N., Yusof, S., Hamid, N. S. A., & Rahman, R. A. (2006). Optimization of enzymatic clarification of sapodilla juice using response surface methodology. Journal of Food Engineering, 73(4), 313–319. https://doi.org/10.1016/j.jfoodeng.2005.01.031

Tankesh, K., Smith, D. D., Kumar, S., & Vimla, B. (2018). Effect of voltage gradient and temperature on electrical conductivity of grape (Vitis vinifera L.) juice during ohmic heating. International Journal of Current Microbiology and Applied Sciences, 7, 1914–1921. https://doi.org/10.20546/ijcmas.2018.705.224

Tunç, M. T., Akdoğan, A., Baltacı, C., Kaya, Z., & Odabaş, H. İ. (2022). Production of grape pekmez by ohmic heating-assisted vacuum evaporation. Food Science and Technology International, 28(1), 72–84. https://doi.org/10.1177/1082013221991616

Zainal, B. S., Rahman, R. A., Ariff, A. B., Saari, B. N., & Asbi, B. A. (2000). Effects of temperature on the physical properties of pink guava juice at two different concentrations. Journal of Food Engineering, 43(1), 55–59. https://doi.org/10.1016/S0260-8774(99)00132-6

Acknowledgements

The authors are grateful to Acharya N.G. Ranga Agricultural University, Andhra Pradesh, India, for providing all the facilities required to carry out the experiments.

Funding

Funding on research work was received from Acharya N.G. Ranga Agricultural University, Andhra Pradesh, India.

Author information

Authors and Affiliations

Contributions

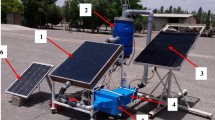

V. Vasudeva Rao proposed idea, constructed test cell, prepared material, collected test data, analyzed the data, and drafted the manuscript. Venkata S.P. Bitra revised the text of manuscript and interpreted the results.

Corresponding author

Ethics declarations

Ethics Approval

This manuscript is the original research work carried out and the contents are true to the best of our knowledge. This work was carried out by the authors and it is not published anywhere else in any form.

Informed Consent

Informed consent not applicable.

Consent for Publication

All the authors are agreeable for publication in the journal.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• In the concentration process using OHVE, maximum guava juice concentration was attained with the least amount of processing time.

• Guava juice that was treated with OHVE showed more viscosity, less color change, and less ascorbic acid degradation.

• The OHVE process resulted in concentrated guava juice of better quality.

• When compared to rotary vacuum concentration, the OHVE method is more rapid and produced concentrated guava juice of superior quality.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Vangapandu, V.R., Bitra, V.S.P. Optimization of Process Parameters of Ohmic Heating-Assisted Vacuum Evaporation of Guava Juice and Quality Assessment of Its Concentrate. Food Bioprocess Technol 16, 1609–1624 (2023). https://doi.org/10.1007/s11947-023-03019-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-023-03019-y