Abstract

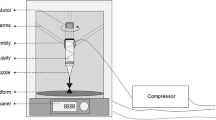

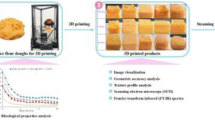

3D food printing is revolutionizing the food manufacturing process and offers unmatched levels of customization in terms of appearance and nutrition. Though flesh foods have a huge market potential, to date, no study details the printability of chicken meat. This study reports the printability of ground chicken meat; refined wheat flour was used as an additive at different levels of ground chicken meat (1:1, 2:1, and 3:1, w/w) to improve its printability. For the optimized 2:1 formulation, extrusion printing variables such as nozzle height (0.64 mm), nozzle size (0.82 mm), printing speed (1000 mm/min), extrusion rate (8.8 mm3/s), extrusion motor speed (360 rpm), and extrusion pressure (4 bar) were optimized. The 3D-printed sample was post-processed by hot-air drying followed by deep frying. Crispy 3D-printed chicken nuggets with an energy value of 166.72 ± 0.07 kcal/100 g could be made available in any customized shape, providing insights for futuristic applications, particularly in the fast-food industry.

Similar content being viewed by others

References

Abu, N., Syahariza, Z., & Abidin, Z. (2018). Rheological studies on the effect of different thickeners in texture- modified chicken rendang for individuals with dysphagia. Journal of Food Science and Technology, 55(11), 4522–4529. https://doi.org/10.1007/s13197-018-3386-5.

Ağar, B., Gençcelep, H., Saricaoğlu, F. T., & Turhan, S. (2016). Effect of sugar beet fiber concentrations on rheological properties of meat emulsions and their correlation with texture profile analysis. Food and Bioproducts Processing, 100, 118–131. https://doi.org/10.1016/j.fbp.2016.06.015.

Alam, M. S., Kaur, J., Khaira, H., & Gupta, K. (2016). Extrusion and extruded products: changes in quality attributes as affected by extrusion process parameters: a review. Critical Reviews in Food Science and Nutrition, 56(3), 445–473.

Anukiruthika, T., Moses, J. A., & Anandharamakrishnan, C. (2020). 3D printing of egg yolk and white with rice flour blends. Journal of Food Engineering, 265, 109691. https://doi.org/10.1016/j.jfoodeng.2019.109691.

Anvari, M., & Joyner, H. S. (2019). Concentrated emulsions as novel fat replacers in reduced-fat and low-fat Cheddar cheeses. Part 2. Large amplitude oscillatory shear behavior. International Dairy Journal, 91, 137–146. https://doi.org/10.1016/j.idairyj.2018.08.018.

AOAC, I. (2016). Official Methods of Analysis. In M. A. I. Rockville (ed.); 20th ed.

Boland, M., Kaur, L., Chian, F. M., & Astruc, T. (2018). Muscle proteins. In Encyclopedia of Food Chemistry. https://doi.org/10.1016/B978-0-08-100596-5.21602-8.

Bortnowska, G., Krzemińska, N., & Mojka, K. (2013). Effects of waxy maize and potato starches on the stability and physicochemical properties of model sauces prepared with fresh beef meat. International Journal of Food Science and Technology, 48(12), 2668–2675. https://doi.org/10.1111/ijfs.12263.

Chen, H., Xie, F., Chen, L., & Zheng, B. (2019). Effect of rheological properties of potato, rice and corn starches on their hot-extrusion 3D printing behaviors. Journal of Food Engineering, 244, 150–158. https://doi.org/10.1016/j.jfoodeng.2018.09.011.

Choi, Y.-S., Han, D.-J., Choi, J.-H., Hwang, K.-E., Song, D.-H., Kim, H.-W., Kim, Y.-B., & Kim, C.-J. (2016). Effect of chicken skin on the quality characteristics of semi-dried restructured jerky. Poultry Science, 95(5), 1198–1204.

Coogan, T. J., & Kazmer, D. O. (2019). In-line rheological monitoring of fused deposition modeling. Journal of Rheology, 63(1), 141–155. https://doi.org/10.1122/1.5054648.

Coombs, C. E. O., Holman, B. W. B., Michael, A., & Hopkins, D. L. (2016). PT SC. Meat Science, 125, 84–94. https://doi.org/10.1016/j.meatsci.2016.11.025.

Dankar, I., Pujolà, M., El Omar, F., Sepulcre, F., & Haddarah, A. (2018). Impact of mechanical and microstructural properties of potato puree-food additive complexes on extrusion-based 3D printing. Food and Bioprocess Technology, 11(11), 2021–2031. https://doi.org/10.1007/s11947-018-2159-5.

Dick, A., Bhandari, B., & Prakash, S. (2019a). 3D printing of meat. In Meat Science (Vol. 153, pp. 35–44). Elsevier Ltd.. https://doi.org/10.1016/j.meatsci.2019.03.005.

Dick, A., Bhandari, B., & Prakash, S. (2019b). Post-processing feasibility of composite-layer 3D printed beef. Meat Science, 153, 9–18. https://doi.org/10.1016/j.meatsci.2019.02.024.

Dick, A., Bhandari, B., Dong, X., & Prakash, S. (2020). Feasibility study of hydrocolloid incorporated 3D printed pork as dysphagia food. Food Hydrocolloids, 107, 105940. https://doi.org/10.1016/j.foodhyd.2020.105940.

Dong, X., Huang, Y., Pan, Y., Wang, K., Prakash, S., & Zhu, B. (2019). Investigation of sweet potato starch as structural enhancer for 3D printing of Scomberomorus niphonius surimi. Journal of Texture Studies, 50(4), 1–24. https://doi.org/10.1111/jtxs.12398.

Eilert, S. J., Blackmer, D. S., Mandigo, R. W., & Calkins, C. R. (1993). Meat batters manufactured with modified beef connective tissue. Journal of Food Science, 58(4), 691–696. https://doi.org/10.1111/j.1365-2621.1993.tb09336.x.

Harper, W. J., Hewitt, S. A., & Huffman, L. M. (2020). Chapter 15 - Model food systems and protein functionality. In M. Boland & H. Singh (Eds.), Milk Proteins (Third Edition) (pp. 573–598). Academic Press. https://doi.org/10.1016/B978-0-12-815251-5.00015-3.

Huang, M., Zhang, M., & Bhandari, B. (2019). Assessing the 3D printing precision and texture properties of brown rice induced by infill levels and printing variables. Food and Bioprocess Technology, 1–12. https://doi.org/10.1007/s11947-019-02287-x.

Keerthana, K., Anukiruthika, T., Moses, J. A., & Anandharamakrishnan, C. (2020). Development of fiber-enriched 3D printed snacks from alternative foods: a study on button mushroom. Journal of Food Engineering, 287, 110116. https://doi.org/10.1016/j.jfoodeng.2020.110116.

Kim, H. W., Lee, J. H., Park, S. M., Lee, M. H., Lee, I. W., Doh, H. S., & Park, H. J. (2018). Effect of hydrocolloids on rheological properties and printability of vegetable inks for 3D food printing. Journal of Food Science, 83(12), 2923–2932.

Krishnaraj, P., Anukiruthika, T., Choudhary, P., Moses, J. A., & Anandharamakrishnan, C. (2019). 3D extrusion printing and post-processing of fibre-rich snack from indigenous composite flour. Food and Bioprocess Technology, 12(10), 1776–1786. https://doi.org/10.1007/s11947-019-02336-5.

Kumar, S., Anukiruthika, T., Dutta, S., Kashyap, A. V., Moses, J. A., & Anandharamakrishnan, C. (2020). Iron deficiency anemia: a comprehensive review on iron absorption, bioavailability and emerging food fortification approaches. Trends in Food Science and Technology, 99, 58–75. https://doi.org/10.1016/j.tifs.2020.02.021.

Li, Y., Wang, Q., Guo, L., Ho, H., Wang, B., Sun, J., Xu, X., & Huang, M. (2019). Effects of ultrafine comminution treatment on gelling properties of myofibrillar proteins from chicken breast. Food Hydrocolloids, 97, 105199.

Lipton, J., Arnold, D., Nigl, F., Lopez, N., Cohen, D., Noren, N., & Lipson, H. (2010, August). Multi-material food printing with complex internal structure suitable for conventional post-processing. Paper presented at the 21st Annual International Solid Freeform Fabrication Symposium - An Additive Manufacturing Conference, SFF 2010, (United States), Austin, Texas (pp. 809–815).

Liu, C., Ho, C., & Wang, J. (2018a). The development of 3D food printer for printing fibrous meat materials. IOP Conference Series: Materials Science and Engineering, 284(1), 012019. https://doi.org/10.1088/1757-899X/284/1/012019.

Liu, Z., Zhang, M., Bhandari, B., & Yang, C. (2018b). Impact of rheological properties of mashed potatoes on 3D printing. Journal of Food Engineering, 220, 76–82. https://doi.org/10.1016/j.jfoodeng.2017.04.017.

Liu, L., Meng, Y., Bhandari, B., Dai, X., Chen, K., Zhu, Y., & Prakash, S. (2019a). Correction to: 3D printing complex egg white protein objects: properties and optimization. Food and Bioprocess Technology, 12(2), 280.

Liu, Y., Yu, Y., Liu, C., Regenstein, J. M., Liu, X., & Zhou, P. (2019b). Rheological and mechanical behavior of milk protein composite gel for extrusion-based 3D food printing. Lwt, 102, 338–346. https://doi.org/10.1016/j.lwt.2018.12.053.

Liu, Y., Zhang, W., Wang, K., Bao, Y., Mac Regenstein, J., & Zhou, P. (2019c). Fabrication of gel-like emulsions with whey protein isolate using microfluidization: rheological properties and 3D printing performance. Food and Bioprocess Technology, 12(12), 1967–1979.

Liu, Y., Tang, T., Duan, S., Qin, Z., Zhao, H., Wang, M., Li, C., Zhang, Z., Liu, A., Han, G., et al. (2020a). Applicability of rice doughs as promising food materials in extrusion-based 3D printing. Food and Bioprocess Technology, 13(3), 548–563.

Liu, Z., Bhandari, B., & Zhang, M. (2020b). Incorporation of probiotics (Bifidobacterium animalis subsp. Lactis) into 3D printed mashed potatoes: Effects of variables on the viability. Food Research International, 128, 108795.

Liu, Z., Dick, A., Prakash, S., Bhandari, B., & Zhang, M. (2020c). Texture modification of 3D printed air-fried potato snack by varying its internal structure with the potential to reduce oil content. Food and Bioprocess Technology, 13(3), 564–576.

Nachal, N., Moses, J. A., Karthik, P., & Anandharamakrishnan, C. (2019). Applications of 3D printing in food processing. Food Engineering Reviews, 11(3), 123–141. https://doi.org/10.1007/s12393-019-09199-8.

Nida, S., Anukiruthika, T., Moses, J. A., & Anandharamakrishnan, C. (2020). 3D printing of grinding and milling fractions of rice husk. Waste and Biomass Valorization, 1–10. https://doi.org/10.1007/s12649-020-01000-w.

Pallottino, F., Hakola, L., Costa, C., Antonucci, F., Figorilli, S., Seisto, A., & Menesatti, P. (2016). Printing on food or food printing: a review. Food and Bioprocess Technology, 9(5), 725–733.

Park, J. M., & Kim, J. M. (2016). Monitoring of used frying oils and frying times for frying chicken nuggets using peroxide value and acid value. Korean Journal for Food Science of Animal Resources, 36(5), 612–616. https://doi.org/10.5851/kosfa.2016.36.5.612.

Pulatsu, E., Su, J.-W., Lin, J., & Lin, M. (2020). Factors affecting 3D printing and post-processing capacity of cookie dough. Innovative Food Science & Emerging Technologies, 61, 102316.

Rahimi, D., Kashaninejad, M., Ziaiifar, A. M., & Mahoonak, A. S. (2018). Effect of infrared final cooking on some physico-chemical and engineering properties of partially fried chicken nugget. Innovative Food Science & Emerging Technologies, 47, 1–8.

Saldaña, E., Saldarriaga, L., Cabrera, J., Behrens, J. H., Selani, M. M., Rios-mera, J., & Contreras-, C. J., Selani, M. M., Rios-mera, J., & Contreras-castillo, C. J. (2018). Descriptive and hedonic sensory perception of Brazilian consumers for smoked bacon. Meat Science, 147, 60–69. https://doi.org/10.1016/j.meatsci.2018.08.023.

Santhi, D., Kalaikannan, A., & Sureshkumar, S. (2017). Factors influencing meat emulsion properties and product texture: a review. Critical Reviews in Food Science and Nutrition, 57(10), 2021–2027. https://doi.org/10.1080/10408398.2013.858027.

Sariçoban, C., Yilmaz, M. T., Karakaya, M., & Tiske, S. S. (2010). The effect of different levels of sunflower head pith addition on the properties of model system emulsions prepared from fresh and frozen beef. Meat Science, 84(1), 186–195. https://doi.org/10.1016/j.meatsci.2009.08.046.

Severini, C., Derossi, A., Ricci, I., Caporizzi, R., & Fiore, A. (2017). SC. Journal of Food Engineering, 220, 89–100. https://doi.org/10.1016/j.jfoodeng.2017.08.025.

Severini, C., Derossi, A., Ricci, I., Caporizzi, R., & Fiore, A. (2018). Printing a blend of fruit and vegetables. New advances on critical variables and shelf life of 3D edible objects. Journal of Food Engineering, 220, 89–100. https://doi.org/10.1016/j.jfoodeng.2017.08.025.

Singh, S., Mehta, N., Chatli, M. K., & Malav, O. P. (2019). Consumer studies on meat consumption and processing pattern through contact survey in different zones of Ludhiana City. Journal of Animal Research, 9(4), 605–611.

Smith, D. M. (2000). Functional properties of muscle proteins in processed poultry products. Poultry Meat Processing. https://doi.org/10.1201/b15805-12.

Statista. (2020). Processed Meat. https://www.statista.com/outlook/40020300/100/processed-meat/worldwide#market-revenue. Accessed 15 May 2020.

Sun, J., Zhou, W., Huang, D., Fuh, J. Y. H., & Hong, G. S. (2015). An overview of 3D printing technologies for food fabrication. Food and Bioprocess Technology, 8(8), 1605–1615.

Tamsen, M., Shekarchizadeh, H., & Soltanizadeh, N. (2018). Evaluation of wheat flour substitution with amaranth flour on chicken nugget properties. LWT, 91, 580–587.

Theagarajan, R., Moses, J. A., & Anandharamakrishnan, C. (2020). 3D extrusion printability of rice starch and optimization of process variables. Food and Bioprocess Technology, 13(6), 1048–1062. https://doi.org/10.1007/s11947-020-02453-6.

Thielke, S., Lhafi, S. K., & Kühne, M. (2005). Effects of aging prior to freezing on poultry meat tenderness. Poultry Science, 84(4), 607–612. https://doi.org/10.1093/ps/84.4.607.

Tornberg, E. (2013). Engineering processes in meat products and how they influence their biophysical properties. Meat Science, 95(4), 871–878.

Wang, L., Zhang, M., Bhandari, B., & Yang, C. (2018). Investigation on fish surimi gel as promising food material for 3D printing. Journal of Food Engineering, 220, 101–108. https://doi.org/10.1016/j.jfoodeng.2017.02.029.

Xiong, Y. L. (2017). Structure-function relationships of muscle proteins. In Food Proteins and their Applications. https://doi.org/10.1201/9780203755617.

Xiong, Y. L. (2018). Chapter 5 - Muscle proteins. In R. Y. Yada (Ed.), Proteins in food processing (Second Edition) (pp. 127–148). Woodhead Publishing. https://doi.org/10.1016/B978-0-08-100722-8.00006-1.

Yang, F., Zhang, M., Bhandari, B., & Liu, Y. (2017). SC. LWT - Food Science and Technology, 87, 67-76. https://doi.org/10.1016/j.lwt.2017.08.054.

Yang, F., Zhang, M., Prakash, S., & Liu, Y. (2018a). Physical properties of 3D printed baking dough as affected by different compositions. Innovative Food Science and Emerging Technologies, 49(2017) Elsevier Ltd. https://doi.org/10.1016/j.ifset.2018.01.001.

Yang, F., Zhang, M., Bhandari, B., & Liu, Y. (2018b). Investigation on lemon juice gel as food material for 3D printing and optimization of printing parameters. LWT - Food Science and Technology, 87, 67–76. https://doi.org/10.1016/j.lwt.2017.08.054.

Yang, F., Guo, C., Zhang, M., Bhandari, B., & Liu, Y. (2019). Improving 3D printing process of lemon juice gel based on fluid flow numerical simulation. LWT, 102, 89–99.

Zhang, L., Lou, Y., & Schutyser, M. A. I. (2018). 3D printing of cereal-based food structures containing probiotics. Food Structure, 18, 14–22.

Zhu, Y., Li, C., Cui, H., & Lin, L. (2020). Plasma enhanced-nutmeg essential oil solid liposome treatment on the gelling and storage properties of pork meat batters. Journal of Food Engineering, 266, 109696.

Funding

The authors acknowledge funding received from the Ministry of Food Processing Industries (MoFPI), Govt. of India for this research work (Grant No.: Q-11/16/2018-R&D).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wilson, A., Anukiruthika, T., Moses, J.A. et al. Customized Shapes for Chicken Meat–Based Products: Feasibility Study on 3D-Printed Nuggets. Food Bioprocess Technol 13, 1968–1983 (2020). https://doi.org/10.1007/s11947-020-02537-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-020-02537-3