Abstract

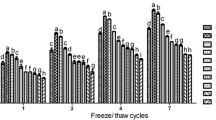

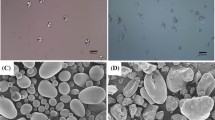

The influence of temperature-time gelatinisation conditions on the gel forming kinetics and final gel mechanical features of commonly used starches as potato starch was studied. The proximate physicochemical properties of potato starch as well as the thermorheological and textural characteristics of the corresponding potato starch gels (native, NPS, and at different GD, PS) were determined. Thermorheological testing at small amplitude oscillatory shear and texture profile analysis were used to evaluate the systems structure evolution and the final gel texture, respectively. High purity (total starch content > 98.5 ± 0.7% dry basis, d.b.), intermediate amylose content (21.2 ± 0.8%), low damaged starch levels (2.7 ± 0.8%), crystallinity (B-pattern) level of 22.9 ± 1.1% and average particle size (60.3 ± 4.3 μm) were the main physicochemical features of tested NPS. Rheological outcomes indicated that only potato starch samples heated at temperatures above 50 °C for tested gelatinisation times were able to form gels. The largest gel strength was identified for NPS, PS70:20 (temperature/time) and PS80 independently of gelatinisation time. Viscoelasticity of PS85 and PS90 gels significantly drop with increasing temperature-time gelatinisation conditions. Temperatures between peak (58 °C) and final (70 °C) gelatinisation temperatures favour the formation of stronger and fully thermal reversible gels, remaining practically invariant until 80 °C. Texture studies indicated that an acceptable linear dependence (R 2 > 0.96) between viscoelastic gel properties determined by rheology and textural parameters can be established.

Similar content being viewed by others

References

Alcázar-Alay, S. C., & Meireles, M. A. A. (2015). Physicochemical properties, modification and applications of starches from different botanical sources. Food Science and Technology, 35, 215–236.

AOAC. (2000). Official Methods of Analysis (17th ed.). Washington: Association of Official Analytical Chemistry.

ASAE Standards. (1995). S319.2: Methods for determining and expressing fineness of feed materials by sieving. Michigan: American Society of Agricultural Engineers.

Bhattacharjya, B., Dutta, H., Patwari, K., & Mahanta, C. L. (2015). Properties of annealed jackfruit (Artocarpus heterophyllus Lam.) seed starch. Acta Alimentaria, 44, 501–510.

Brites, C., Trigo, M. J., Santos, C., Collar, C., & Rosell, C. M. (2008). Maize based gluten-free bread: influence of processing parameters on sensory and instrumental quality. Food Bioprocess Technology, 3, 707–715.

Charoenkul, N., Uttapap, D., Pathipanawat, W., & Takeda, Y. (2011). Physicochemical characteristics of starches and flours from cassava varieties having different cooked root textures. LWT - Food Science and Technology, 44, 1774–1781.

Cheetham, N. W. H., & Tao, L. (1998). Variation in crystallinity type with amylose content in maize starch granules: an X-ray powder diffraction study. Carbohydrate Polymers, 36, 277–284.

Chenlo, F., Moreira, R., Prieto, D. M., & Torres, M. D. (2011). Desorption isotherms and net isosteric heat of chestnut flour and starch. Food and Bioprocess Technology, 4, 1497–1504.

Cornejo-Villegas, M. A., Acosta-Osorio, A. A., Rojas-Molina, I., Gutiérrez-Cortéz, E., Quiroga, M. A., Gaytán, M., Herrera, G., & Rodríguez-García, M. E. (2010). Study of the physicochemical and pasting properties of instant corn flour added with calcium and fibers from nopal powder. Journal of Food Engineering, 96, 401–409.

Correia, P., Cruz-Lopes, L., & Beirão-da-Costa, L. (2012). Morphology and structure of chestnut starch isolated by alkali and enzymatic methods. Food Hydrocolloids, 28, 313–319.

Genovese, D. B., & Rao, M. A. (2003). Role of starch granule characteristics (volume fraction, rigidity and fractal dimension) on rheology of starch dispersions with and without amylose. Cereal Chemistry, 80, 350–355.

Glampedaki, P., Petzold, G., Dutschk, V., Miller, R., & Warmoeskerken, M. C. G. (2012). Physicochemical properties of biopolymer-based polyelectrolyte complexes with controlled pH/thermo-responsiveness. Reactive and Functional Polymers, 72, 458–468.

Gunaratne, A., & Hoover, R. (2002). Effect of heat-moisture treatment on the structure and physicochemical properties of tuber and root starches. Carbohydrate Polymers, 49, 425–437.

Houben, A., Götz, H., Mitzscherling, M., & Becker, T. (2010). Modification of the rheological behavior of amaranth (Amaranthus hypochondriacus) dough. Journal of Cereal Science, 51, 350–356.

Jan, K. N., Panesar, P. S., Rana, J. C., & Singh, S. (2017). Structural, thermal and rheological properties of starches isolated from Indian quinoa varieties. International Journal of Biological Macromolecules, 102, 315–322.

Jena, R., & Bhattacharya, S. (2003). Viscoelastic characterization of rice gel. Journal of Texture Studies, 34, 349–360.

Jiménez, A., Fabra, M. J., Talens, P., & Chiralt, A. (2012). Edible and biodegradable starch films: a review. Food and Bioprocess Technology, 5, 2058–2076.

Joshi, M., Aldred, P., Panozzo, J. F., & Kasapis, S. (2014). Rheological and microstructural characteristics of lentil starch-lentil protein composite pastes and gels. Food Hydrocolloids, 35, 226–237.

Lagarrigue, S., & Alvarez, G. (2010). The rheology of starch dispersions at high temperature and high shear rates: a review. Journal of Food Engineering, 50, 189–202.

Lai, P., Li, K. Y., Lu, S., & Chen, H. H. (2011). Physicochemical characteristics of rice starch supplemented with dietary fibre. Food Chemistry, 127, 153–158.

Lan, W., Hihua, Y., Yun, Z., Bijun, X., & Zhida, S. (2008). Morphological, physicochemical and textural properties of starch separated from Chinese water chestnut. Starch-Starke, 60, 181–191.

Lawal, O. S., Lapasin, R., Bellich, B., Olayiwola, T. O., Cesàro, A., Yoshimura, M., & Nishinari, K. (2011). Rheology and functional properties of starches isolated from five improved rice varieties from West Africa. Food Hydrocolloids, 25, 1785–1792.

Li, G., Wang, S., & Zhu, F. (2016). Physicochemical properties of quinoa starch. Carbohydrate Polymers, 137, 328–338.

Malumba, P., Jacquet, N., Delimme, G., Lefebvre, F., & Béra, F. (2013). The swelling behavior of wheat starch granules during isothermal and non-isothermal treatments. Journal of Food Engineering, 114, 199–206.

Manohar, R. S., & Rao, P. H. (2002). Interrelationship between rheological characteristic of dough and quality of biscuits; use of elastic recovery of dough to predict biscuit quality. Food Research International, 35, 807–813.

Marco, C., & Rosell. (2008). Rice. In E. K. Arendt & F. Dal Bello (Eds.), Gluten free cereal product and beverages. London: Academic Press.

Moreira, R., Chenlo, F., Torres, M. D., & Glazer, J. (2012). Rheological properties of gelatinized chestnut starch dispersions: effect of concentration and temperature. Journal of Food Engineering, 112, 94–99.

Moreira, R., Chenlo, F., Torres, M. D., & Rama, B. (2013). Influence of the chestnuts drying temperature on the rheological properties of their doughs. Food and Bioproducts Processing, 91, 7–13.

Nunes, M. C., Raymundo, A., & Sousa, I. (2006). Rheological behaviour and microstructure of pea protein/k-carrageenan/starch gels with different setting conditions. Food Hydrocolloids, 20, 106–113.

Onyango, C., Unbehend, G., & Lindhuaer, M. G. (2009). Effect of cellulose-derivatives and emulsifiers on creep-recovery and crumb properties of gluten-free bread prepared from sorghum and gelatinized starch. Food Research International, 42, 949–955.

Pérez-Santos, D. M., Velazquez, G., Canonico-Franco, M., Morales-Sanchez, E., Gaytan-Martínez, M., Yañez-Limon, J. M., & Herrera-Gomez, A. (2016). Modelling the limited degree of starch gelatinization. Starch/Stärke, 68, 727–733.

Przetaczek-Roznowska, I. (2017). Physicochemical properties of starches isolated from pumpkin compared with potato and corn starches. International Journal of Biological Macromolecules, 101, 536–542.

Santos, E., Rosell, C. M., & Collar, C. (2008). Retrogradation kinetics of high fibre wheat flour blends: a calorimetric approach. Cereal Chemistry, 85, 450–458.

Sasaki, T., Kohyama, K., & Yasui, T. (2004). Effect of water-soluble and insoluble non-starch polysaccharides isolated from wheat flour on the rheological properties of wheat starch gel. Carbohydrate Polymers, 57, 451–458.

Sheikha, A. F. E., & Ray, R. C. (2017). Potential impacts of bioprocessing of sweet potato: review. Critical Reviews in Food Science and Nutrition, 57, 455–471.

Sodhi, N. S., Sasaki, T., Lu, Z.-H., & Kohyama, K. (2010). Phenomenological viscoelasticity of some rice starch gels. Food Hydrocolloids, 24, 512–517.

Tananuwong, K., & Reid, D. (2004). DSC and NMR relaxation studies of starch-water interactions during gelatinization. Carbohydrate Polymers, 58, 345–358.

Torres, M. D., Chenlo, F., & Moreira, R. (2017). Thermal reversibility of kappa/iota-hybrid carrageenan gels extracted from Mastocarpus stellatus at different ionic strengths. Journal of the Taiwan Institute of Chemical Engineers, 71, 414–420.

Torres, M. D., Fradinho, P., Raymundo, A., & Sousa, I. (2014a). Thermorheological and textural behaviour of gluten-free gels obtained from chestnut and rice flours. Food and Bioprocess Technology, 7, 1171–1182.

Torres, M. D., Moreira, R., Chenlo, F., Morel, M. H., & Barron, C. (2014b). Physicochemical and structural properties of starch isolated from fresh and dried chestnuts and chestnut flour. Food Technology and Biotechnology, 52, 135–139.

Wang, H., Zhang, B., Chen, L., & Li, X. (2016). Understanding the structure and digestibility of heat-moisture treated starch. International Biological Macromolecules, 88, 1–8.

Wani, I. A., Sogi, D. S., Hamdani, A. M., Gani, A., Bhat, N. A., & Shah, A. (2016). Isolation, composition, and physicochemical properties of starch from legumes: a review. Starch/Strakë, 68, 834–845.

Waterschoot, J., Gomand, S. V., Fierens, E., & Delcour, J. A. (2015). Starch blends and their physicochemical properties. Starch-Starke, 67, 1–13.

Witczak, M., Ziobro, R., Juszczak, L., & Korus, J. (2015). Starch and starch derivatives in gluten-free systems—a review. Journal of Cereal Science, 67, 46–57.

Zhang, D., Mu, T., & Sun, H. (2017a). Calorimetric, rheological, and structural properties of potato protein and potato starch composites and gels. Starch/Stärke, 69, 1600329.

Zhang, B., Selway, N., Shelata, K. J., Dhital, S., Stokes, J. R., & Gidleya, M. J. (2017b). Tribology of swollen starch granule suspensions from maize and potato. Carbohydrate Polymers, 155, 128–135.

Acknowledgements

The authors acknowledge the financial support (ED431B) to the Consellería de Cultura, Educación e Ordenación Universitaria (Xunta de Galicia) and the use of RIAIDT-USC analytical facilities for X-ray diffraction measurements.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Torres, M.D., Chenlo, F. & Moreira, R. Rheological Effect of Gelatinisation Using Different Temperature-Time Conditions on Potato Starch Dispersions: Mechanical Characterisation of the Obtained Gels. Food Bioprocess Technol 11, 132–140 (2018). https://doi.org/10.1007/s11947-017-2000-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-017-2000-6