Abstract

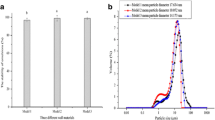

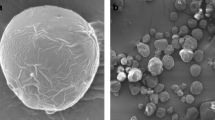

Sacha Inchi (Plukenetia volubilis L.) oil (SIO) is one of the vegetable oils with the highest content of polyunsaturated fatty acids (about 50% α-linolenic acid, and 35% linoleic acid), thus being prone to oxidation. The aim of this study was to evaluate the effects of the emulsion composition on the physical properties and oxidative stability of SIO microencapsulated by spray drying using modified starch (Hi-Cap 100) and maltodextrin in a mass ratio of 75:25, as wall material. The processing yield (PY), microencapsulation efficiency (MEE), and some selected physical properties (moisture content, A w , color, sorption isotherms, flowing and thermal stability) of the SIO microcapsules (SIO-M) were investigated as a function of the oil loading (10, 20, and 30%) and the concentration of wall material solids (20 and 30%). The obtained results indicated that both the PY and MEE were significantly reduced as the oil loading increased, varying from 50 to 35%, and between 96 and 82%, respectively. FTIR analyses revealed that SIO was effectively encapsulated into the wall material. SIO-M were spherical in shape, and showed high oxidation stability upon accelerated tests. According to the thermogravimetric analysis, SIO-M could resist the pasteurization and sterilization processes used in the food industry, without suffering thermal decomposition. The sorption isotherms of SIO-M fitted better with the Guggenheim-Anderson-de Boer model. These results indicate that SIO could be successfully microencapsulated by spray drying using Hi-Cap 100 and maltodextrin as wall materials, from emulsions with a concentration of 30% wall material, and 20 to 30% oil loading.

Similar content being viewed by others

References

Aghbashlo, M., Mobli, H., Madadlou, A., & Rafiee, S. (2012). Influence of wall material and inlet drying air temperature on the microencapsulation of fish oil by spray drying. Food and Bioprocess Technology, 6(6), 1561–1569.

Alamilla-Beltrán, L., Chanona-Pérez, J., Jiménez-Aparicio, A., & Gutiérrez-López, G. (2005). Description of morphological changes of particles along spray drying. Journal of Food Engineering, 67(1–2), 179–184.

AOAC (2012). Official methods of analysis of AOAC International (19th ed.). Gaithersburg, Maryland, USA: Association of Official Analytical Chemists

Barbosa-Cánovas, G. V., Ortega-Rivas, E., Juliano, P., & Yan, H. (2005). Food powders—physical properties, processing, and functionality (food Engineering series). New York: Kluwer Academic/Plenum Publishers.

Beirão da Costa, S., Duarte, C., Bourbon, A. I., Pinheiro, A. C., Serra, A. T., Moldão Martins, M., et al. (2012). Effect of the matrix system in the delivery and in vitro bioactivity of microencapsulated oregano essential oil. Journal of Food Engineering, 110(2), 190–199.

Botrel, D. A., Rodrigues, I. C. B., Souza, H. J. B., & de Barros, R. V. (2016). Application of inulin in thin-layer drying process of araticum (Annona crassiflora) pulp. LWT-Food Science and Technology, 69, 32–39.

Brunauer, S., Deming, L. S., Deming, W. E., & Teller, E. (1940). On a theory of the van der Waals adsorption of gases. Journal of the American Chemical Society, 62(7), 1723–1732.

Carneiro, H. C. F., Tonon, R. V., Grosso, C. R. F., & Hubinger, M. D. (2013). Encapsulation efficiency and oxidative stability of flaxseed oil microencapsulated by spray drying using different combinations of wall materials. Journal of Food Engineering, 115(4), 443–451.

Castro-Albarrán, J., Aguilar-Uscanga, B. R., Calon, F., St-Amour, I., Solís-Pacheco, J., Saucier, L., et al. (2016). Spray and freeze drying of human milk on the retention of immunoglobulins (IgA, IgG, IgM). Drying Technology, 34(15), 1801–1809.

Cisneros, F. H., Paredes, D., Arana, A., & Cisneros-Zevallos, L. (2014). Chemical composition, oxidative stability and antioxidant capacity of oil extracted from roasted seeds of Sacha-Inchi (Plukenetia volubilis L.) Journal of Agricultural and Food Chemistry, 62(22), 5191–5197.

de Barros, R. V., Borges, S. V., & Botrel, D. A. (2013). Influence of spray drying operating conditions on microencapsulated rosemary essential oil properties. Food Science and Technology (Campinas), 33, 171–178.

de Barros, R. V., Marques, G. R., Borges, S. V., & Botrel, D. A. (2014a). Effect of solids content and oil load on the microencapsulation process of rosemary essential oil. Industrial Crops and Products, 58, 173–181.

de Barros, R. V., Borges, S. V., Botrel, D. A., & Oliveira, C. R. (2014b). Physical and chemical properties of encapsulated rosemary essential oil by spray drying using whey protein–inulin blends as carriers. International Journal of Food Science & Technology, 49(6), 1522–1529.

de Barros, R. V., Borges, S. V., Silva, E. K., da Silva, Y. F., de Souza, H. J. B., do Carmo, E. L., et al. (2016). Study of ultrasound-assisted emulsions on microencapsulation of ginger essential oil by spray drying. Industrial Crops and Products, 94, 413–423.

FAO/WHO (2001). Codex Standard for Named Vegetable Oils (CODEX-STAN 210–1999). In FAO/WHO (Ed.), THE CODEX ALIMENTARIUS - Fats, Oils and Related Products (Second ed., Vol. 8). Rome, Italy

Firestone, D. (1997). Official Methods and Recommended Practices of the AOCS (4ed.): American Oil Chemists’ Society

Follegatti-Romero, L. A., Piantino, C. R., Grimaldi, R., & Cabral, F. A. (2009). Supercritical CO2 extraction of omega-3 rich oil from Sacha inchi (Plukenetia volubilis L.) seeds. The Journal of Supercritical Fluids, 49(3), 323–329.

Gallardo, G., Guida, L., Martinez, V., López, M. C., Bernhardt, D., Blasco, R., et al. (2013). Microencapsulation of linseed oil by spray drying for functional food application. Food Research International, 52(2), 473–482.

Guillén, M. D., Ruiz, A., Cabo, N., Chirinos, R., & Pascual, G. (2003). Characterization of sacha inchi (Plukenetia volubilis L.) oil by FTIR spectroscopy and 1H NMR. Comparison with linseed oil. Journal of the American Oil Chemists' Society, 80(8), 755–762.

Gutiérrez, L.-F., Ratti, C., & Belkacemi, K. (2008). Effects of drying method on the extraction yields and quality of oils from quebec sea buckthorn (Hippophaë rhamnoides L.) seeds and pulp. Food Chemistry, 106(3), 896–904.

Gutierrez, L.-F., Rosada, L. M., & Jimenez, A. (2011). Chemical composition of Sacha Inchi (Plukenetia volubilis L.) seeds and characteristics of their lipid fraction. Grasas y Aceites, 62(1), 76–83.

Hamaker, B. R., Valles, C., Gilman, R., Hardmeier, R. M., Clark, D., Garcia, H. H., et al. (1992). Amino acid and fatty acid profiles of the Inca peanut (Plukenetia volubilis). Cereal Chemistry, 69, 461–463.

Janiszewska, E., Jedlińska, A., & Witrowa-Rajchert, D. (2015). Effect of homogenization parameters on selected physical properties of lemon aroma powder. Food and Bioproducts Processing, 94, 405–413.

Jimenez, M., García, H. S., & Beristain, C. I. (2004). Spray-drying microencapsulation and oxidative stability of conjugated linoleic acid. European Food Research and Technology, 219(6), 588–592.

Karim, F. T., Sarker, Z. M., Ghafoor, K., Al-Juhaimi, F. Y., Jalil, R.-U., Awang, M. B., et al. (2016). Microencapsulation of fish oil using hydroxypropyl methylcellulose as a carrier material by spray drying. Journal of Food Processing and Preservation, 40(2), 140–153.

Kaushik, P., Dowling, K., Barrow, C. J., & Adhikari, B. (2015). Microencapsulation of omega-3 fatty acids: a review of microencapsulation and characterization methods. Journal of Functional Foods, 19(Part B), 868–881.

Koç, B., Sakin-Yılmazer, M., Kaymak-Ertekin, F., & Balkır, P. (2014). Physical properties of yoghurt powder produced by spray drying. Journal of Food Science and Technology, 51(7), 1377–1383.

Koç, M., Güngör, Ö., Zungur, A., Yalçın, B., Selek, İ., Ertekin, F., et al. (2015). Microencapsulation of extra virgin olive oil by spray drying: effect of wall materials composition, process conditions, and emulsification method. Food and Bioprocess Technology, 8(2), 301–318.

Osorio, C., Forero, D. P., & Carriazo, J. G. (2011). Characterisation and performance assessment of guava (Psidium guajava L.) microencapsulates obtained by spray-drying. Food Research International, 44(5), 1174–1181.

Özer, B. H., & Kirmaci, H. A. (2010). Functional milks and dairy beverages. International Journal of Dairy Technology, 63(1), 1–15.

Polavarapu, S., Oliver, C. M., Ajlouni, S., & Augustin, M. A. (2011). Physicochemical characterisation and oxidative stability of fish oil and fish oil-extra virgin olive oil microencapsulated by sugar beet pectin. Food Chemistry, 127(4), 1694–1705.

Pourashouri, P., Shabanpour, B., Razavi, S. H., Jafari, S. M., Shabani, A., & Aubourg, S. P. (2014). Oxidative stability of spray-dried microencapsulated fish oils with different wall materials. Journal of Aquatic Food Product Technology, 23(6), 567–578.

Quispe-Condori, S., Saldaña, M. D., & Temelli, F. (2011). Microencapsulation of flax oil with zein using spray and freeze drying. LWT-Food Science and Technology, 44(9), 1880–1887.

Ribeiro, A., Ruphuy, G., Lopes, J. C., Dias, M. M., Barros, L., Barreiro, F., et al. (2015). Spray-drying microencapsulation of synergistic antioxidant mushroom extracts and their use as functional food ingredients. Food Chemistry, 188, 612–618.

Roccia, P., Martínez, M. L., Llabot, J. M., & Ribotta, P. D. (2014). Influence of spray-drying operating conditions on sunflower oil powder qualities. Powder Technology, 254, 307–313.

Saavedra-Leos, Z., Leyva-Porras, C., Araujo-Diaz, S. B., Toxqui-Teran, A., & Borras-Enriquez, A. J. (2015). Technological application of maltodextrins according to the degree of polymerization. Molecules, 20(12), 21067–21081.

Sahin-Nadeem, H., & Afşin Özen, M. (2014). Physical properties and fatty acid composition of pomegranate seed oil microcapsules prepared by using starch derivatives/whey protein blends. European Journal of Lipid Science and Technology, 116(7), 847–856.

Santiago-Adame, R., Medina-Torres, L., Gallegos-Infante, J. A., Calderas, F., González-Laredo, R. F., Rocha-Guzmán, N. E., et al. (2015). Spray drying-microencapsulation of cinnamon infusions (Cinnamomum zeylanicum) with maltodextrin. LWT-Food Science and Technology, 64(2), 571–577.

Shishir, M. R. I., Taip, F. S., Aziz, N. A., & Talib, R. A. (2014). Physical properties of spray-dried pink guava (Psidium guajava) powder. Agriculture and Agricultural Science Procedia, 2, 74–81.

Silva, V. M., Vieira, G. S., & Hubinger, M. D. (2014). Influence of different combinations of wall materials and homogenisation pressure on the microencapsulation of green coffee oil by spray drying. Food Research International, 61, 132–143.

Simopoulos, A. P. (2002). The importance of the ratio of omega-6/omega-3 essential fatty acids. Biomedicine & Pharmacotherapy, 56(8), 365–379.

de Souza, V. B., Thomazini, M., de Balieiro, J. C. C., & Fávaro-Trindade, C. S. (2015). Effect of spray drying on the physicochemical properties and color stability of the powdered pigment obtained from vinification byproducts of the Bordo grape (Vitis labrusca). Food and Bioproducts Processing, 93, 39–50.

Staudt, P. B., Tessaro, I. C., Marczak, L. D. F., de Soares, R. P., & Cardozo, N. S. M. (2013). A new method for predicting sorption isotherms at different temperatures: extension to the GAB model. Journal of Food Engineering, 118(3), 247–255.

Sun-Waterhouse, D., & Waterhouse, G. N. (2015). Spray-drying of green or gold kiwifruit juice–milk mixtures; novel formulations and processes to retain natural fruit colour and antioxidants. Food and Bioprocess Technology, 8(1), 191–207.

Toledo Hijo, A. A. C., da Costa, J. M. G., Silva, E. K., Azevedo, V. M., Yoshida, M. I., & Borges, S. V. (2015). Physical and thermal properties of oregano (Origanum vulgare L.) essential oil microparticles. Journal of Food Process Engineering, 38(1), 1–10.

Tonon, R. V., Baroni, A. F., Brabet, C., Gibert, O., Pallet, D., & Hubinger, M. D. (2009). Water sorption and glass transition temperature of spray dried açai (Euterpe oleracea Mart.) juice. Journal of Food Engineering, 94(3–4), 215–221.

Tonon, R. V., Pedro, R. B., Grosso, C. R. F., & Hubinger, M. D. (2012). Microencapsulation of flaxseed oil by spray drying: effect of oil load and type of wall material. Drying Technology, 30(13), 1491–1501.

Vongsvivut, J., Heraud, P., Zhang, W., Kralovec, J. A., McNaughton, D., & Barrow, C. J. (2012). Quantitative determination of fatty acid compositions in micro-encapsulated fish-oil supplements using Fourier transform infrared (FTIR) spectroscopy. Food Chemistry, 135(2), 603–609.

Wandrey, C., Bartkowiak, A., & Harding, S. E. (2010). Materials for encapsulation. In N. J. Zuidam & V. A. Nedović (Eds.), Encapsulation technologies for active food ingredients and food processing (pp. 31–100). New York: Springer-Verlag.

Wibowo, S., Vervoort, L., Tomic, J., Santiago, J. S., Lemmens, L., Panozzo, A., et al. (2015). Colour and carotenoid changes of pasteurised orange juice during storage. Food Chemistry, 171, 330–340.

Acknowledgments

This work was supported by the Instituto de Ciencia y Tecnología de Alimentos (ICTA) of the Universidad Nacional de Colombia, project “Corredor Tecnológico Agroindustrial Bogotá y Cundinamarca Derivado 2.” Authors acknowledge Yolanda Quiñones Segura for her technical assistance in the chemical analyses.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sanchez-Reinoso, Z., Gutiérrez, LF. Effects of the Emulsion Composition on the Physical Properties and Oxidative Stability of Sacha Inchi (Plukenetia volubilis L.) Oil Microcapsules Produced by Spray Drying. Food Bioprocess Technol 10, 1354–1366 (2017). https://doi.org/10.1007/s11947-017-1906-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-017-1906-3