Abstract

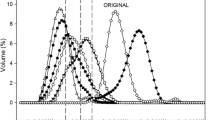

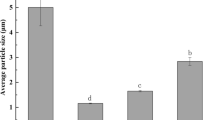

This study was conducted to investigate the effects of inulin (0, 2.5, 5, and 7.5 %), maltodextrin (0, 15, 20, and 25 %), and different drying processes (one- and two-stage drying) on the morphology and physicochemical properties of regular and instant reduced-fat creamers. The present study showed that the drum-dried creamer containing 0 % maltodextrin and 0 % inulin was fully sticky powder with dark brown color. It was found that the maximum increase in maltodextrin (from 0 to 25 %) and inulin (from 0 to 7.5 %) resulted in the creamer with the highest glass transition temperature and the lowest stickiness among all formulated creamers. The application of two-stage drying involving fluidized bed drying resulted in further improvement of the glass transition temperature and stickiness of the reduced fat instant creamer. The instant creamers obtained from two-stage drying had considerably higher glass transition temperature and lower bulk density than the regular creamers from one-stage drying. Such improvement could be due to the reduction of bulk density induced by fluidized bed drying. This might be because of higher porosity of the creamer particles after agglomeration. The current study revealed that the addition of high amounts of inulin and maltodextrin also played a significant role in the reduction of bulk density and further improvement of glass transition temperature (Tg) and solubility of the reduced fat creamer. The instant reduced fat creamer containing 25 % maltodextrin and 7.5 % inulin had the most desirable characteristics among all formulated creamers.

Similar content being viewed by others

References

Abiad, M. G., Gonzalez, D. C., Mert, B., Campanella, O. H., & Carvajal, M. T. (2010). A novel method to measure the glass and melting transitions of pharmaceutical powders. International Journal of Pharmaceutics, 396(1), 23–29.

Adhikari, B., Howes, T., Bhandari, B. R., & Truong, V. (2003). Characterization of the surface stickiness of fructose–maltodextrin solutions during drying. Drying Technology, 21, 17–34.

ADPI (American Dairy Products Institute). (1992). Standards for grades of dry milk including method of analysis. Bull. 916. Chicago, IL, USA.

Akinori, M., Masata, M., & Masao, M. (1998). Effect of crystallinity on the glass transition temperature of starch. Journal of Agricultural and Food Chemistry, 46, 98–103.

Bhandari, B. R., Datta, N., & Howes, T. (1997). Problem associated with spray drying of sugar–rich foods. Drying Technology, 15, 671–684.

Bröckel, U., Wahl, M., Kirsch, R., & Feise, H. J. (2006). Formation and growth of crystal bridges in bulk solids. Chemical Engineering & Technology, 29, 691–695.

Caric, M. (2003). Milk powders: types and manufacture and physical and functional properties of milk powders. In H. Roginski, J. W. Fuquay, & P. F. Fox (Eds.), Encyclopedia of dairy sciences (pp. 1869–1880). New York: Academic.

Chen, X. D., & Özkan, N. (2007). Stickiness, functionality, and microstructure of food powders. Drying Technology, 25, 959–969.

Chung, M. S., Ruan, R. R., Chen, P., Chung, S. H., Ahn, T. H., & Lee, K. H. (2000). Study of caking in powdered foods using nuclear magnetic resonance spectroscopy. Journal of Food Science, 65, 134–138.

Cruz, M. A. A., Passos, M. L., & Ferreira, W. R. (2005). Final drying of whole milk powder in vibrated-fluidized beds. Drying Technology, 23, 2021–2037.

Dacanal, G. C., & Menegalli, F. C. (2010). Selection of operational parameters for the production of instant soy protein isolate by pulsed fluid bed agglomeration. Powder Technology, 203(3), 565–573.

Descamps, N., Palzer, S., Roos, Y. H., & Fitzpatrick, J. J. (2013). Glass transition and flowability/caking behaviour of maltodextrin DE 21. Journal of Food Engineering, 119, 809–813.

Dhanalakshmi, K., & Bhattacharya, S. (2014). Agglomeration of turmeric powder and its effect on physico-chemical and microstructural characteristics. Journal of Food Engineering, 120, 124–134.

Dhanalakshmi, K., Ghosal, S., & Bhattacharya, S. (2011). Agglomeration of food powder and applications. Critical Reviews in Food Science and Nutrition, 51(5), 432–441.

El-Nagar, G., Clowes, G., Tudoricǎ, C. M., Kuri, V., & Brennan, C. S. (2002). Rheological quality and stability of yoghurt-ice cream with added inulin. International Journal of Dairy Technology, 55, 89–93.

Fitzpatrick, J. J., Barry, K., Cerqueira, P. S. M., Iqbal, T., O’Neill, J., & Roos, Y. H. (2007). Effect of composition and storage conditions on the flowability of dairy powders. International Dairy Journal, 17, 383–392.

Fox, T. G., & Flory, P. J. (1950). Second-order transition temperatures and related properties of polystyrene. Journal of Applied Physics, 21, 581–591.

Glibowski, P., & Bukowska, A. (2011). The effect of pH, temperature and heating time on inulin chemical stability. Acta Scientiarum Polonorum Seria: Technologia Alimentaria, 10, 189–196.

Golde, A. E., & Schmidt, K. A. (2005). Quality of coffee creamers as a function of protein source. Journal of Food Quality, 28(1), 46–61.

Goula, A. M., & Adamopoulos, K. G. (2005). Spray drying of tomato pulp in dehumidified air: II. The effect on powder properties. Journal of Food Engineering, 66, 35–42.

Goula, A. M., & Adamopoulos, K. G. (2008). Effect of maltodextrin addition during spray drying of tomato pulp in dehumidified air: II. powder properties. Drying Technology, 26, 726–737.

Goula, A. M., & Adamopoulos, K. G. (2010). A new technique for spray drying orange juice concentrate. Innovative Food Science & Emerging Technologies, 11, 342–351.

Griffin, V. K., & Brooks, J. R. (1989). Production and size distribution of rice maltodextrins hydrolyzed from milled rice flour using heat‐stable alpha‐amylase. Journal of Food Science, 54, 190–193.

Hooda, S., & Jood, S. (2005). Organoleptic and nutritional evaluation of wheat biscuits supplemented with untreated and treated fenugreek flour. Food Chemistry, 90, 427–435.

Hursh, H., & Martin, J. (2005). Low-carb and beyond: the health benefits of inulin. Cereal Foods World, 50, 57–60.

Jakubczyk, E., Ostrowska‐Ligeza, E., & Gondek, E. (2010). Moisture sorption characteristics and glass transition temperature of apple puree powder. International Journal of Food Science and Technology, 45, 2515–2523.

Jinapong, N., Suphantharika, M., & Jamnong, J. (2008). Production of instant soymilk powders by ultrafiltration, spray drying and fluidized bed agglomeration. Journal of Food Engineering, 84, 194–205.

Kage, M., Yang, Q., Sato, H., Matsumoto, S., Kaji, R., Akiguchi, I., & Tooyama, I. (2001). Acidic fibroblast growth factor (FGF-1) in the anterior horn cells of ALS and control cases. Neuroreport, 12, 3799–3803.

Kalogiannia, E. P., Xynogalos, V. A., Karapantsios, T. D., & Kostloglou, M. (2002). Effect of feed concentration on the production of pregelatinized starch in a double drum dryer. LWT- Food Science and Technology, 35(8), 703–711.

Kasapis, S. (2005). Glass transition phenomena in dehydrated model systems and foods: a review. Drying Technology, 23, 731–757.

Kelly, P. M., Oldfield, D. J., & O’Kennedy, B. T. (1999). The thermostability of spray dried imitation coffee whiteners. International Journal of Dairy Technology, 52, 107–113.

Kha, T. C., Nguyen, M. H., & Roach, P. D. (2010). Effects of spray drying conditions on the physicochemical and antioxidant properties of the Gac (Momordica cochinchinensis) fruit aril powder. Journal of Food Engineering, 98, 385–392.

Kim, Y., Faqih, M. N., & Wang, S. S. (2001). Factors affecting gel formation of inulin. Carbohydrate Polymers, 46, 135–145.

Le Meste, M., Champion, D., Roudaut, G., Blond, G., & Simatos, D. (2002). Glass transition and food technology: a critical appraisal. Journal of Food Science, 67, 2444–2458.

Mirhosseini, H., Tan, C. P., Hamid, N. S. A., & Yusof, S. (2009). Characterization of the influence of main emulsion components on cloudiness, size index, conductivity and emulsion stability of orange beverage emulsion using response surface methodology. Food Hydrocolloids, 23, 271–280.

Musielak, G., & Mierzwa, D. (2009). Permanent strains in clay-like material during drying. Drying Technology, 27(7–8), 894–902.

Nindo, C. I., & Tang, J. (2007). Refractance Window dehydration technology: a novel contact drying method. Drying Technology, 25(1), 37–48.

Oldfield, D., & Singh, H. (2005). Functional properties of milk powders. Food SScience and Technology-New York-Marcel Dekker, 146, 365.

Papadakis, S. E., Gardeli, C., & Tzia, C. (1998). Raisin extract powder: production, physical and sensory properties. In Proc. 11th International Drying Symposium IDS (Vol. 98, pp. 1207–1213).

Peleg, M., & Mannheim, C. H. (1977). The mechanism of caking of powdered onion. Journal of Food Processing and Preservation, 1, 3–11.

Potter, N. N. (1968). Food science. Westport: AVI Publishing Company.

Pua, C. K., Hamid, N. S. A., Tan, C. P., Mirhosseini, H., Rahman, R. B. A., & Rusul, G. (2010). Optimization of drum drying processing parameters for production of jackfruit (Artocarpus heterophyllus) powder using response surface methodology. LWT--Food Science and Technology, 43, 343–349.

Ren, G. Y., Li, D., Wang, L. J., Özkan, N., & Mao, Z. H. (2010). Morphological properties and thermoanalysis of micronized cassava starch. Carbohydrate Polymers, 79, 101–105.

Ronkart, S. N., Blecker, C. S., Fourmanoir, H., Fougnies, C., et al. (2007). Isolation and identification of inulooligosaccharides resulting from inulin hydrolysis. Analytica Chimica Acta, 604, 81–87.

Roos, Y. H. (1995). Glass transition-related physicochemical changes in foods: chemical and rheological changes during phase transition in food. Food Technology, 49(10), 97–102.

Schuck, P., Jeantet, R., & Dolivet, A. (2012). Analytical methods for food and dairy powders. John Wiley & Sons.

Schuck, P., le Floch-Fouere, C., & Jeantet, R. (2013). Changes in functional properties of milk protein powders: effects of vacuum concentration and drying. Drying Technology, 31, 1578–1591.

Singh, A. K., Selvam, R. P., & Sivakumar, T. (2010). Isolation, characterisation and formulation properties of a new plant gum obtained from mangifera indica. International Journal of Pharmacy Biomedical Research, 1, 35–41.

Tabatabaee Amid, B., & Mirhosseini, H. (2012). Optimization of aqueous extraction of gum from Durian (Durio zibethinus) seed: a potential, low cost source of hydrocolloid. Food Chemistry, 132, 1258–1268.

Uthumporn, U., Zaidul, I. S., & Karim, A. A. (2010). Hydrolysis of granular starch at sub-gelatinization temperature using a mixture of amylolytic enzymes. Food and Bioproducts Processing, 88, 47–54.

Vega-Mercado, H., Marcela Gongora-Nieto, M., & Barbosa-Cánovas, G. V. (2001). Advances in dehydration of foods. Journal of Food Engineering, 49, 271–289.

WHO (Word health organization) (2012). Bulk density and tapped density of powders. Document QAS/11.450.

Acknowledgments

We gratefully appreciate the financial support from Ministry of Science, Technology, and Innovation for EScience Fund (03-01-04-SF1884).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hedayatnia, S., Mirhosseini, H., Tamnak, S. et al. Improvement of Glass Transition and Flowability of Reduced-Fat Coffee Creamer: Effect of Fat Replacer and Fluidized Bed Drying. Food Bioprocess Technol 9, 686–698 (2016). https://doi.org/10.1007/s11947-015-1666-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-015-1666-x