Abstract

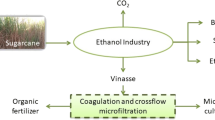

In this work, the crossflow microfiltration (CFMF) performance of different lots of lager beer, produced in a pilot scale at the Italian Brewing Research Centre (CERB, Perugia, Italy), was assessed in a bench-top plant, equipped with a 0.8-μm ceramic tubular membrane module, under constant crossflow velocity of 6 m s−1, transmembrane pressure difference of 3.74 bar, temperature of ~10 °C, and periodic CO2 backflushing. By feeding different beer samples (i.e., as such, precentrifuged (C), or pretreated with a commercial enzyme preparation to degrade the original arabinoxylans and β-glucans and then centrifuged (EC) to minimize the fouling contribution of yeast cells, aggregates, and polysaccharides), it was possible to increase the average permeation flux (expressed as mean value ± standard deviation) from 112 ± 13 to 199 ± 17 or 330 ± 22 L m−2 h−1, respectively. Only when using the EC-pretreated beer specimens, the permeate turbidity at 20 °C approached the limiting one (<0.6 EBC unit) recommended by the European Brewery Convention standards. As expected, the permeate chill haze at 0 °C was generally higher than the above haze target. By submitting EC-pretreated beer seeded with 0.5 g L−1 of regenerable polyvinylpolypyrrolidone (PVPP) to CFMF, it was possible to reduce the initial total polyphenol content by 30 % and permeate chill haze to 0.60 ± 0.01 EBC unit, but the average permeation flux fell to 84 ± 4 L m−2 h−1. By performing sequentially EC pretreatments, PVPP stabilization, cartridge filtration, and CFMF, it was possible not only to re-enhance the average permeation flux at about 230 L m−2 h−1 near to those achievable with DE filters, but also to obtain a chill haze-free permeate ready for aseptic packaging.

Similar content being viewed by others

Abbreviations

- A :

-

Alcohol content of beer (% v/v)

- A m0 :

-

Initial membrane surface area (m2)

- BG:

-

β-Glucan content of beer (g m−3)

- C:

-

Beer color (EBC unit)

- CFMF:

-

Crossflow microfiltration

- DE:

-

Diatomaceous earth or kieselguhr

- EBC:

-

European Brewery Convention

- H :

-

Beer turbidity [EBC unit]

- i :

-

Index expressing the generic i-th instantaneous value of any dependent variable y j to be used in Eqs. (5) and (6)

- J * :

-

Quasi-steady-state permeation flux (L m−2 h−1)

- J v :

-

Instantaneous volumetric permeation flux (L m−2 h−1)

- j :

-

Generic dependent variable to be fitted by the fouling model used here

- k CF :

-

Cake filtration constant (s m−2)

- L W :

-

Membrane constant for water transport (L m−2 h−1 bar−1)

- MSPE j :

-

Generic j-th mean squared percentage error, as defined by Eq. (6)

- N :

-

Number of experimental data

- OE:

-

Beer original extract [°Plato]

- PVPP:

-

Polyvinylpolypyrrolidone

- r 2 :

-

Coefficient of determination

- R irr :

-

Irreversible fouling resistance (m−1)

- R m :

-

Intrinsic membrane resistance (m−1)

- Rrev :

-

Reversible fouling resistance (m−1)

- R T :

-

Overall membrane resistance (m−1)

- RB:

-

Rough beer

- RE:

-

Beer real extract (°Plato)

- s 2 j :

-

Generic j-th residual variance, as defined by Eq. (5)

- T :

-

Process temperature (°C)

- t :

-

Process time (s or h)

- TMPD:

-

Transmembrane pressure difference (bar)

- TP:

-

Total phenol content (mg L−1)

- V :

-

Cumulative volume of filtrate (L)

- v S :

-

Crossflow velocity (m s−1)

- y j :

-

Generic j-th dependent variable

- η:

-

Filtrate dynamic viscosity (mPa s)

- ρ:

-

Density of filtrate (kg L−1)

- av:

-

Average

- calc:

-

Calculated

- exp:

-

Experimental

- J :

-

Referred to permeation flux

- V :

-

Referred to volume

- 0:

-

Initial

References

Analytica, E. B. C. (2010). European brewery convention. Nürnberg: Fachverlag Hans Carl.

Bolton, G., LaCasse, D., & Kuriyel, R. (2006). Combined models of membrane fouling: development and application to microfiltration and ultrafiltration of biological fluids. Journal of Membrane Science, 277, 75–84.

Buttrick, P. (2007). Filtration—the facts. Brewer & Distiller International, 3(12), 12–19.

Cimini, A. (2013). Novel lager beer clarification and stabilisation process using ceramic tubular microfiltration membranes. In Proc.s 18th Workshop on the Developments in the Italian PhD Research on Food Science Technology and Biotechnology, pp. 45-50, V. Corich, E. Celotti, eds. Padova, Italy: Padova University Press.

Cimini, A., Marconi, O., & Moresi, M. (2013). Rough beer clarification by crossflow microfiltration in combination with enzymatic and/or centrifugal pretreatments. Chemical Engineering Transactions, 32, 1729–1734.

Cimini, A., & Moresi, M. (2013). Chiarificazione della birra con membrana ceramica tubolare. Industria delle Bevande, 42(245), 9–17.

Eßlinger, H. M. (2009). Handbook of brewing and beer processes—technology—markets (1st ed.). Weinheim: Federal Republic of Germany: Wiley-VCH Verlag GmbH.

Fillaudeau, L., Blanpain-Avet, P., & Daufin, G. (2006). Water, wastewater and waste management in brewing industries. Journal of Cleaner Production, 14, 463–471.

Gan, Q., Howell, J. A., Field, R. W., England, R., Bird, M. R., & McKechinie, M. T. (1999). Synergetic cleaning procedure for a ceramic membrane fouled by beer microfiltration. Journal of Membrane Science, 155, 277–289.

Meier, J. (1993). Filtration process, use of stabilizers, installation for a filtration process, and procedure for operating said installation. US Patent No. 5262053.

Mélotte, L. (2008). Measurements of beer colloidal stability. In Proc.s XIIIth J. De Clerck Chair: The paradox in alcoholic beverages: a beer and wine paradox? Louvain-la-Neuve (Belgium), September 7-10, 2008. Available at: http://www.uclouvain.be/cps/ucl/doc/inbr/documents/DeClerckChairMelotte.pdf. Accessed 12 March 2014.

Montgomery, D. C. (2005). Design and analysis of experiments (6th ed., pp. 247–248). New York, USA: John Wiley & Sons, Inc.

Rehmanji, M., Gopal, C., & Mola, A. (2005). Beer stabilization technology—clearly a matter of choice. Master Brewers Association of Americas Technical Quarterly, 42(4), 332–338.

Siebert, K. J., Carrasco, A., & Lynn, P. Y. (1996). Formation of protein-polyphenol haze in beverages. Journal of Agricultural and Food Chemistry, 44, 1997–2005.

Taylor, B., Clem, A., & David, P. (2006). Use of the combined stabilisation system and its impact on beer composition. Brauwelt International, 24, 158–163.

Acknowledgments

This research was supported by the Italian Ministry of Instruction, University and Research, special grant PRIN 2010-2011—prot. 2010ST3AMX_003.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Cimini, A., Marconi, O., Perretti, G. et al. Novel Procedure for Lager Beer Clarification and Stabilization Using Sequential Enzymatic, Centrifugal, Regenerable PVPP and Crossflow Microfiltration Processing. Food Bioprocess Technol 7, 3156–3165 (2014). https://doi.org/10.1007/s11947-014-1306-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1306-x