Abstract

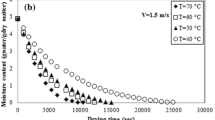

The vacuum-drying characteristics of ginger (Zingiber officinale R.) slices were investigated. Drying experiments were carried out at a constant chamber pressure of 8 kPa, and at four different drying temperatures (40 °C, 50 °C, 60 °C, and 65 °C).The effects of drying temperature on the drying rate and moisture ratio of the ginger samples were evaluated. Efficient model for describing the vacuum-drying process was chosen by fitting five commonly used drying models and a suggested polynomial was fitted to the experimental data. The effective moisture diffusivity and activation energy were calculated using an infinite series solution of Fick’s diffusion equation. The results showed that increasing drying temperature accelerated the vacuum-drying process. All drying experiments had only falling rate period. The goodness of fit tests indicated that the proposed two-term exponential model gave the best fit to experimental results among the five tested drying models. The average effective diffusivity values varied from 1.859 × 10−8 to 4.777 × 10−8 m2/s over the temperature range. The temperature dependence of the effective moisture diffusivity for the vacuum drying of the ginger samples was satisfactorily described by an Arrhenius-type relationship with activation energy value of 35.675 kJ/mol within 40–65 °C temperature range.

Similar content being viewed by others

References

Arevalo-Pinedo, A., & Murr, F. E. M. (2007). Influence of pre-treatments on the drying kinetics during vacuum drying of carrot and pumpkin. Journal of Food Engineering, 80(1), 152–156.

Association of Official Analytical Chemists (AOAC). (1990). Official method of analysis (15th ed.). Virginia: Association of Official Analytical Chemists.

Bruce, D. M. (1985). Exposed-layer barley drying, three models fitted to new data up to 150 °C. Journal of Agricultural Engineering Research, 32, 337–348.

Chandrashekar, S. (2008). Modeling drying kinetics of mustard in fluidized bed. International Journal of Food Engineering, 4(3), 1–14.

Crank, J. (1975). The mathematics of diffusion. Oxford: Clarendon.

Elsa, U., Antonio, V. G., Karina, D. S., Romina, O., Jorge, S. T., & Margarita, M. (2009). Characteristics of convective drying of Pepino fruit (Solanum muricatum Ait.): application of weibull distribution. Food and Bioprocess Technology. doi:10.1007/s11947-009-0230-y (in press).

Elsa, U., Margarita, M., Antonio, V. G., Issis, Q., Rodrigo, C., & Karina, D. S. (2010). Mass transfer modeling during osmotic dehydration of Jumbo squid (Dosidicus gigas): influence of temperature on diffusion coefficients and kinetics parameters. Food and Bioprocess Technology. doi:10.1007/s11947-010-0336-2 (in press).

Ergunes, G., & Tarhan, S. (2006). Color retention of red pepper by chemical pretreatments during greenhouse and open sun drying. Journal of Food Engineering, 76, 446–452.

German, E., Marek, M., Ireneusz, B., & Magdalena, Z. (2008). Approach to calculation time-dependent moisture diffusivity for thin layered biological materials. International Communications in Heat and Mass Transfer, 35(9), 1069–1072.

Gunhan, T., Demir, V., Hancioglu, E., & Hepbasli, A. (2005). Mathematical modeling of drying of bay leaves. Energy Conversion and Management, 46, 1667–1679.

Henderson, S. M., & Pabis, S. (1961). Grain drying theory I: temperature effect on drying coefficient. Journal of Agricultural Engineering Research, 7, 85–89.

Jaya, S., & Das, H. (2003). A vacuum drying model for mango pulp. Drying Technology, 21(7), 1215–1234.

Koc, A. B., Toy, M., Hayoglu, I., & Vardin, H. (2004). Performance of a solar dryer used for red pepper drying. J. Agric. Fac. HR. U., 8(2), 57–65.

Lopes Filho, J. F., Romanelli, P. F., Barboza, S. H. R., Gabas, A. L., & Telis-Romero, J. (2002). Sorption isotherms of alligator's meat (Caiman crocodilus yacare). Journal of Food Engineering, 52(2), 201–206.

Mohapatra, D., & Rao, P. S. (2005). A thin layer drying model of parboiled wheat. Journal of Food Engineering, 66, 513–518.

Rahman, M. S., Perera, C. O., & Thebaud, C. (1997). Desorption isotherm and heat pump drying kinetics of peas. Food Research International, 30, 485–491.

Wu, L., Orikasa, T., Ogawa, Y., & Tagawa, A. (2007). Vacuum drying characteristics of eggplants. Journal of Food Engineering, 83, 422–429.

Yaldiz, O., & Ertekin, C. (2001). Thin layer solar drying of some vegetables. Drying Technology, 19, 583–596.

Yaldiz, O., Ertekin, C., & Uzun, H. I. (2001). Mathematical modelling of thin layer solar drying of Sultana grapes. Energy, 26(5), 457–465.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Thorat, I.D., Mohapatra, D., Sutar, R.F. et al. Mathematical Modeling and Experimental Study on Thin-Layer Vacuum Drying of Ginger (Zingiber Officinale R.) Slices. Food Bioprocess Technol 5, 1379–1383 (2012). https://doi.org/10.1007/s11947-010-0429-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-010-0429-y