Abstract

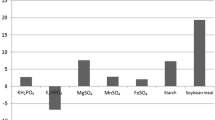

Statistical evaluation of fermentation conditions and nutritional factors by Plackett–Burman two-level factorial design followed by optimization of significant parameters using response surface methodology for lipase production by Bacillus brevis was performed in submerged batch fermentation. Temperature, glucose, and olive oil were found to be the significant factors affecting lipase production. Maximum lipase activity of 5.1 U ml−1 and cell mass of 1.82 g l−1 at 32 h were obtained at the optimized conditions of temperature, 33.7 °C; initial pH, 8; and speed of agitation, 100 rpm, with the medium components: olive oil, 13.73 ml l−1; glucose, 13.98 g l−1; peptone, 2 g l−1; Tween 80, 5 ml l−1; NaCl, 5 g l−1; CH3COONa, 5 g l−1; KCl, 2 g l−1; CaCl2·2H2O, 1 g l−1; MnSO4·H2O, 0.5 g l−1; FeSO4·7H2O, 0.1 g l−1; and MgSO4·7H2O, 0.01 g l−1. The lipase productivity and specific lipase activity were found to be 0.106 U (ml h)−1 and 2.55 U mg−1, respectively. Unstructured kinetic models and artificial neural network models were used to describe the lipase fermentation. The kinetic analysis of the lipase fermentation by B. brevis shows that lipase is a growth-associated product.

Similar content being viewed by others

References

Abdel-Fattah, Y. R. (2002). Optimization of thermostable lipase production from a thermophilic Geobacillus sp. using Box-Behnken experimental design. Biotechnological Letters, 24(14), 1217–1222.

Abdel-Fattah, Y. R., & Olama, Z. A. (2002). L-asparaginase production by Pseudomonas aeruginosa in solid-state culture: evaluation and optimization of culture conditions using factorial designs. Process Biochemistry, 38, 115–122.

Anson, M. L. (1938). The estimation of pepsin, trypsin, papain and cathepsin with hemoglobin. The Journal of General Physiology, 22, 79–89.

Aravindan, R., & Viruthagiri, T. (2007). Optimization of medium composition for lipase production by Candida rugosa NCIM 3462 using response surface methodology. Canadian Journal of Microbiology, 53(5), 643–655.

Aravindan, R., & Viruthagiri, T. (2008). Evaluation of various unstructured kinetic models for protease production by Bacillus sphaericus MTCC 511. Engineering in Life sciences, 8(2), 179–185.

Arifin, N., Peng, K. S., Long, K., Ping, T. C., Yusoff, M. S. A., & Ming, L. O. (2010). Modeling and optimization of Lipozyme RM IM-catalyzed esterification of medium- and long-chain triacyglycerols (MLCT) using response surface methodology. Food and Bioprocess Technology. doi:10.1007/s11947-010-0325-5.

Box, G. E. P., & Behnken, D. W. (1960). Some new three level design for the study of quantitative variables. Technometrics, 2(4), 455–475.

Chakravarthi, R., & Sahai, V. (2002). Optimization of compactin production in chemically defined production medium by Penicillin citrinum using statistical methods. Process Biochemistry, 38, 481–486.

Chandrashekar, K., Felse, P. A., & Panda, T. (1999). Optimization of temperature and initial pH and kinetic analysis of tartaric acid production by Gluconobacter suboxydans. Bioprocess and Biosystems Engineering, 20(3), 203–207.

Chen, S. J., Cheng, C. Y., & Chen, T. L. (1998). Production of an alkaline lipase by Acinetobacter radioresistens. Journal of Fermentation and Bioengineering, 86, 308–312.

Cruz, P. M., Christen, P., & Farres, A. (1993). Medium optimization by a fractional factorial design for lipase production by Rhizopus delemar. Journal of Fermentation and Bioengineering, 76(2), 94–97.

Deive, F. J., Sanroman, M. A., & Longo, M. A. (2010). A comprehensive study of lipase production by Yarrowia lipolytica CECT 1240 (ATCC 18942): from shake flask to continuous bioreactor. Journal of Chemical Technology and Biotechnology, 85(2), 258–266.

Del Rio, J. L., Serra, P., Valero, F., Poch, M., & Sola, C. (1990). Reaction scheme of lipase production by Candida rugosa growing on olive oil. Biotechnological Letters, 12(11), 835–838.

Elibol, M., & Ozer, D. (2000). Influence of oxygen transfer on lipase production by Rhizopus arrhizus. Process Biochemistry, 36, 325–329.

Essamri, M., Valerie, D., & Louis, C. (1998). Optimization of lipase production by Rhizopus oryzae and study on the stability of lipase activity in organic solvents. Journal of Biotechnology, 60, 97–103.

Ghosh, P. K., Saxena, R. K., Gupta, R., Yadav, R. P., & Davidson, S. (1996). Microbial lipases: production and applications. Science Progress, 79(2), 119–157.

Gordillo, M. A., Sanz, A., Sanchez, A., Valero, F., Montesinos, J. L., Lafuente, J., et al. (1998). Enhancement of Candida rugosa lipase production using different control fed-batch operational strategies. Biotechnology and Bioengineering, 60(2), 156–168.

Gowland, P., Kernick, M., & Sundaram, T. K. (1987). Thermophilic bacterial isolates producing lipase. FEMS Microbiology Letters, 48(3), 339–343.

Griebeler, N., Polloni, A. E., Remonatto, D., Arbter, F., Vardanega, R., Cechet, J. L., et al. (2009). Isolation and screening of lipase-producing fungi with hydrolytic activity. Food and Bioprocess Technology. doi:10.1007/s11947-008-0176-5.

Helisto, P., & Korpela, T. (1998). Effects of detergents on activity of microbial lipases as measured by the nitrophenyl alkanoate esters method. Enzyme and Microbial Technology, 23, 113–117.

Hou, C. T. (1994). pH dependence and thermostability of lipases from cultures from the ARS culture collection. Journal of Industrial Microbiology & Biotechnology, 13(4), 242–248.

Hun, C. J., Rahman, R. N. Z. A., Salleh, A. B., & Basri, M. (2003). A newly isolated organic solvent tolerant Bacillus sphaericus 205y producing organic solvent stable lipase. Biochemical Engineering Journal, 15, 147–151.

Jaeger, K. E., & Reetz, M. T. (1998). Microbial lipases form versatile tools for biotechnology. Trends in Biotechnology, 16, 396–402.

Jose, J., & Kurup, G. M. (1999). Purification and characterization of an extracellular lipase from a newly isolated thermophilc Bacillus pumilus. Indian Journal of Experimental Biology, 37(12), 1213–1217.

Khyami-Horani, H. (1996). Thermotolerant strain of Bacillus licheniformis producing lipase. World Journal of Microbiology & Biotechnology, 12(4), 399–401.

Kim, H. K., Park, S. Y., Lee, J. K., & Oh, T. K. (1998). Gene cloning and characterization of thermostable lipase from Bacillus stearothermophilus L1. Bioscience, Biotechnology, and Biochemistry, 62(1), 66–71.

Li, C. Y., Cheng, C. Y., & Chen, T. L. (2004). Fed-batch production of lipase by Acinetobacter radioresistens using Tween 80 as the carbon source. Biochemical Engineering Journal, 19, 25–31.

Linko, S., Luopa, J., & Zhu, Y. H. (1997). Neural networks as “software sensors” in enzyme production. Journal of Biotechnology, 52(3), 257–266.

Lotti, M., Monticelli, S., Montesinos, J. L., Brocca, S., Valero, F., & Lafuente, J. (1998). Physiological control on the expression and secretion of Candida rugosa lipase. Chemistry and Physics of Lipids, 93, 143–148.

Lowry, O. H., Rosenbrough, M. J., Farr, A. L., & Randell, R. J. (1951). Protein measurement with folin phenol reagent. The Journal of Biological Chemistry, 193, 265–275.

Luedeking, R., & Piret, E. L. (1959). A kinetic study of the lactic acid fermentation. Biotechnology and Bioengineering, 1, 393–412.

Macrae, A. R., & Hammond, R. C. (1985). Present and future applications of lipases. Biotechnology & Genetic Engineering Reviews, 3, 193–217.

Miller, G. L. (1959). Use of dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428.

Montesinos, J. L., Lafuente, J., Gordillo, M. A., Valero, F., & Sola, C. (1995). Structured modeling and state estimation in a fermentation process: Lipase production by Candida rugosa. Biotechnology and Bioengineering, 48, 573–584.

Nahas, E. (1988). Control of lipase production by Rhizopus oligosporus under various growth conditions. Journal of General Microbiology, 134, 227–233.

Ota, Y., & Yamada, K. (1966). Lipase from Candida paralipolytica Part I. Anionic surfactants as the essential activator in the systems emulsified by polyvinyl alcohol. Agricultural and Biological Chemistry, 30(4), 351–358.

Pandey, A., Benjamin, S., Cr, S., Nigam, P., Krieger, N., & Soccol, V. T. (1999). The realm of microbial lipases in biotechnology. Biotechnology and Applied Biochemistry, 29, 119–131.

Plackett, R. L., & Burman, J. P. (1946). The design of optimum multifactorial experiments. Biometrica, 33, 305–325.

Sahin, S., Warna, J., Arvela, P. M., Salmi, T., & Murzin, D. Y. (2010). Kinetic modeling of lipase-mediated one-pot chemo-bio cascade synthesis of R-1-phenyl ethyl acetate starting from acetophenone. Journal of Chemical Technology and Biotechnology, 85(2), 192–198.

Sharma, R., Chisti, Y., & Banerjee, U. C. (2001). Production, purification, characterization and applications of lipase. Biotechnology Advances, 19, 627–662.

Sharma, R., Soni, S. K., Vohra, R. M., Jolly, R. S., Gupta, L. K., & Gupta, J. K. (2002). Production of extracellular alkaline lipase from a Bacillus sp. RSJ1 and its application in ester synthesis. Indian Journal of Microbiology, 42, 49–54.

Shidhu, P., Sharma, R., Soni, S. K., & Gupta, J. K. (1998). Effect of cultural conditions on extracellular alkaline lipase production by Bacillus sp. RS-12 and its characterization. Indian Journal of Microbiology, 38, 9–14.

Silva, W. O. B., Mitidieri, S., Schrank, A., & Vainstein, M. H. (2005). Production and extraction of an extracellular lipase from the entomopathogenic fungus Metarhizium anisopliae. Process Biochemistry, 40(1), 321–326.

Stowe, R. A., & Mayer, R. P. (1966). Efficient screening of process variables. Industrial and Engineering Chemistry, 58(2), 36–40.

Sugihara, A., Tani, T., & Tominaga, Y. (1991). Purification and characterization of a novel thermostable lipase from Bacillus sp. Journal of Biochemistry, 109(2), 211–216.

Sztajer, H., Maliszewska, I., & Wieczorek, J. (1988). Production of exogenous lipases by bacteria, fungi, and actinomycetes. Enzyme and Microbial Technology, 10, 492–497.

Treichel, H., Oliveira, D., Mazutti, M. A., Di Luccio, M., & Oliveira, J. V. (2010). A review on microbial lipases production. Food and Bioprocess Technology, 3, 182–196.

Tyndall, J. D., Sinchaikul, S., Fothergill-Gilmore, L. A., Taylor, P., & Walkinshaw, M. D. (2002). Crystal structure of a thermostable lipase from Bacillus stearothermophilus P1. Journal of Molecular Biology, 323, 859–869.

Valero, F., Ayats, F., Lopez-Santin, J., & Poch, M. (1988). Lipase production by Candida rugosa: fermentation behaviour. Biotechnological Letters, 10(10), 741–744.

Wang, Y. X., Srivastava, K. C., Shen, G. J., & Wang, H. Y. (1995). Thermostable alkaline lipase from a newly isolated thermophilic Bacillus, strain A30-1 (ATCC 53841). Journal of Fermentation and Bioengineering, 79, 433–438.

Weiss, R. M., & Ollis, D. F. (1980). Extracellular Microbial polysaccharides. I. Substrate, biomass, and product kinetic equations for batch xanthan gum fermentation. Biotechnology and Bioengineering, 22, 859–873.

Acknowledgment

The authors gratefully acknowledge the Chemical Engineering Department, Annamalai University for providing facilities to carry out this research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Rajendran, A., Thangavelu, V. Optimization and Modeling of Process Parameters for Lipase Production by Bacillus brevis . Food Bioprocess Technol 5, 310–322 (2012). https://doi.org/10.1007/s11947-010-0387-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-010-0387-4