Abstract

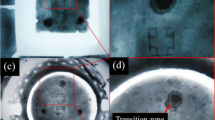

The typical morphology of alloy lead (Pb) in ancient bronzes made in the Spring-Autumn Warring States Period (770 B.C. -221 B.C.), China, was examined by using electron microscopic techniques. We propose that the main purposes for adding metallic Pb in a large quantity into ancient bronzes, such as arrows and ritual vessel—Ding, were for increasing weight and economical reasons. In order to promote adding efficiency and improve casting quality for getting homogenously distributed Pb particles in the bronzes, a process through inserting Pb rod into the mold is supposed to be used during casting, which provided a process for preventing Pb sinkage. Scanning electron microscope (SEM) observations from the fracture surface of the bronzes revealed that the Pb particle possessed a “hollow-cored bubble” structure, which was formed due to absorbing casting gases during solidification and therefore indirectly eliminated the casting porosity and loosen.

Similar content being viewed by others

References

Chasd W T. Ancient Chinese Bronze Art, Casting the Precious Sacral Vessel [M]. New York: China House Gallery, 1991: 250–269.

Wen Renjun. Interpretation and Annotation of Kao Gong Ji [M]. Shanghai: Ancient Books Publishing Company, 1993: 34(Ch).

He Tangkun. Synthetic study on the alloying technique for bronze in the Pre-Qin period [J]. Studies in the History of Natural Sciences, 1997, 16(3): 273–286(Ch).

Scott D A. Metallography and microstructure of ancient and historic metals [M]. Los Angeles: The Getty Conservation Institute, 1991.

Han Rufen, Sun Shuyun, Li Xiuhui, et al. Microstructure of ancient Chinese copper artifacts [J]. Journal of University of Science and Technology Beijing, 2002, 24(2):219–230(Ch).

Li Xiaochen. Metalware techniques of bronze era in Yun’nan [J]. Archaeology and Cultural Relic, 1999, 2: 52–57(Ch).

Qin Ying, Wei Guofeng, Liu Wenqi, et al. Experiments on dissolving lead from bronze wares and the related questions [J]. Science of Conservation and Archaeology, 2005, 17(2): 16–18(Ch).

Yao Zhihui, Sun Shuyun, Zou houxi, et al. Studies on the bronzes excavated from the tombs in the Xiajiang River region [J]. Studies in the History of Natural Science, 2005, 24: 106–118 (Ch).

Lian Haiping, Tan Derui, Wu Zejia, et al. A study on the technology of on the alloyed surface bronze weapons before 2500 years ago [J]. Special Casting & Nonferrous Alloys, 1998, 5: 56–58(Ch).

Lian Haiping, Tan Derui. Study on bimetallic bronze in ancient China [J]. Science of Conservation and Archaeology, 2002, 14(supplement): 312–333(Ch).

Jia Yingzhou, Wei Rong. Metallographic investigation of the Qi State and Ming Dynasty coins [J]. Science of Conservation and Archaeology, 2004, 15(3): 21–30(Ch).

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Supported by the National Natural Science Foundation of China (J1210061)

Biography: LIAO Lingmin, female, Ph. D., research direction: archaeometry.

Rights and permissions

About this article

Cite this article

Liao, L., Pan, C. Relationships between microstructures and properties of chinese ancient bronzes. Wuhan Univ. J. Nat. Sci. 18, 226–232 (2013). https://doi.org/10.1007/s11859-013-0919-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11859-013-0919-7

Key words

- ancient bronze

- Spring-Autumn Warring States Period of China

- casting

- microstructure

- scanning electron microscopy