Abstract

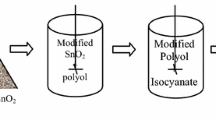

TiO2-based nanosheets (TiNSs), TiO2-based nanotubes (TiNTs) were prepared by hydrothermal processing, and polyurethane foams with TiO2 nanopowders (P25), TiNSs and TiNTs were synthesized by free-rising foaming method. The Fourier-transform infrared (FT-IR) spectra show that the addition of titanium dioxide does not affect the chemical structure of polyurethane foam. However, microscope observations show that PU/TiNSs composite foams have more uniform cells and the average aperture smaller than that of pure polyurethane foams. According to the results of thermal analysis, the PU/TiNSs composite foams have better thermal stability, the temperature of decompostion occurring with a maximum weight loss rate is about 30 °C higher than that of pure PU foams. The decompostion temperatures are 167 °C and 148 °C for the PU/P25 composite foams and the PU/TiNTs composite foams respectively, which are lower than that of pure PU foams. Moreover, with the addition of the fillers, the sound absorption property also has changed; the addition of TiNSs improved the sound absorbing property efficiently. The better thermal stability and sound absorption of PU/TiNSs composite foams are mainly due to the uniform cells diffuse and smaller aperture.

Similar content being viewed by others

References

Lee J, Kim G. H, Ha C S. Sound absorption properties of polyurethane/nano-silica nanocomposite foams [J]. Journal of Applied Polymer Science, 2012, 123(4): 2384–2390.

Gibson L J, Ashby M F. Cellular Solids [M]. Cambridge: Cambridge University Press, 1999.

Li B, Zhou H, Huang G S. A novel impedance matching material derived from polymer micro-particles [J]. Journal of Materials Science, 2007, 42(1): 199–206.

Andersson A, Lundmark S, Magnusson A, et al. Vibration and Acoustic damping of flexible polyurethane foams modified with a hyperbranched polymer [J]. Journal of Cellular Plastics, 2010, 46(1): 73–93.

Lin J H, Lin C M, Huang C C, et al. Evaluation of the manufacture of sound absorbent sandwich plank made of PET/TPU honeycomb grid/PU foam [J]. Journal of Composite Materials, 2011, 45(13): 1355–1362.

Norzali N R, Badri K H, Nuawi M Z. Loading effect of aluminum hydroxide onto the mechanical, thermal conductivity, acoustical and burning properties of the palm-based polyurethane composites [J]. Sains Malaysiana, 2011, 40(7): 737–742.

Song H J, Zhang Z Z, Men X H. Tribological behavior of polyurethane-based composite coating reinforced with TiO2 nanotubes [J]. European Polymer Journal, 2008, 44(4): 1012–1022.

Verdejo R, Stämpfli R, Alvarez-Lainez M, et al. Enhanced acoustic damping in flexible polyurethane foams filled with carbon nanotubes [J]. Composites Science and Technology, 2009, 69(10): 1564–1569.

Sung C H, Lee K S, Lee K S, et al. Sound damping of a polyurethane foam nanocomposite [J]. Macromolecular Research, 2007, 15(5): 443–448.

Saunders J H, Frisch K C. Polyurethanes: Chemistry and Technology of High Polymers [M]. New York: Wiley Interscience, 1962.

Chen J S, Lou X W. Anatase TiO2 nanosheet: An ideal host structure for fast and efficient lithium insertion/extraction [J]. Electrochemistry Communications, 2009, 11(12): 2332–2335.

Akita T, Okumura M, Tanaka K, et al. Transmission electron microscopy observation of the structure of TiO2 nanotube and Au/TiO2 nanotube catalyst [J]. Surface and Interface Analysis, 2005, 37(2): 265–269.

Kavan L, Kalbáč M, Zukalová M, et al. Lithium storage in nanostructured TiO2 made by hydrothermal growth [J]. Chemistry of Materials, 2004, 16(3): 477–485.

Peng C W, Ke T Y, Brohan L, et al. (101)-Exposed anatase TiO2 nanosheets [J]. Chemistry of Materials, 2008, 20(7): 2426–2428.

Mahfuz H, Rangari V K, Islam M S, et al. Fabrication, synthesis and mechanical characterization of nanoparticles infused polyurethane foams [J]. Composites Part A: Applied Science and Manufacturing, 2004, 35(4): 453–460.

Saha M C, Kabir M E, Jeelani S. Enhancement in thermal and mechanical properties of polyurethane foam infused with nanoparticles [J]. Materials Science and Engineering: A, 2008, 479(1–2): 213–222.

Duquesne S, Le Bras M, Bourbigot S, et al. Thermal degradation of polyurethane and polyurethane/expandable graphite coatings [J]. Polymer Degradation and Stability, 2001, 74(3): 493–499.

Ema Y, Ikeya M, Okamoto M. Foam processing and cellular structure of polylactide-based nanocomposites [J]. Polymer, 2006, 47(15): 5350–5359.

Yuan M, Turng L S, Gong S, et al. Study of injection molded microcellular polyamide-6 nanocomposites [J]. Polymer Engineering & Science, 2004, 44 (4): 673–686.

Suhr J, Koratkar N, Keblinski P, et al. Viscoelasticity in carbon nanotube composites [J]. Nature Materials, 2005, 4(2): 134–137.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Supported by the National Natural Science Foundation of China (21174108) and the Fundamental Research Funds for the Central Universities (20102020201000017).

Biography: HE Lijuan, female, Master candidate, research direction: advance functional materials.

Rights and permissions

About this article

Cite this article

He, L., Liu, F., Liu, T. et al. Preparation, structure, and properties of polyurethane foams modified by nanoscale titanium dioxide with three different dimensions. Wuhan Univ. J. Nat. Sci. 17, 377–382 (2012). https://doi.org/10.1007/s11859-012-0858-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11859-012-0858-8