Abstract

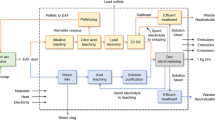

Simulation programs have been devel oped to study the effect of recycling the electric arc furnace dust leaching residues to the furnace. Residues from sulfuric acid and sodium hydroxide leaching have been tested. Results enable the furnace-leaching response to be defined in accord with the recycling rate and conditions for zero stabilization to be determined. Either of the two alternative treatments eliminates the resulting environmental problem. Regarding the management and minimization of residues, the alkaline treatment route is more favorable than the acid one. The preliminary economic evaluation of the alkaline method is very promising.

Similar content being viewed by others

References

K. Bourdeau, “Update on Regulations and Enforcement,” Proc. of the CMP Electric Furnace Dust Treatment Symposium (Pittsburgh, PA: EPRI Center for Materials Production, 1994).

M. Cruels, A. Roca, and C. Nunez, “Electric Arc Furnace Furnace Flue Dusts: Characterization and Leaching with Sulphuric Acid,” Hydrometallurgy, 31 (1992), pp. 213–231.

L.M. Southwick, “Recycling Zinc Recovered from Electric Arc Furnace Dust: Is There a Better Way?” EPD Congress 1998, ed. B. Mishra (Warrendale, PA: TMS, 1998), pp. 465–484.

J.N. Stone, “Treatment of Electric Arc Furnace Dust in Combination with Other Wastes,” Disposal, Recycling and Recovery of Electric Arc Furnace Exhaust Dust (Warrendale, PA: 1987), pp. 167–170.

“La Industria Siderúrgica Española en 1988” (Madrid, Spain: UNESID, 1989), p. 98.

A.O. Hoffman et al., Proc. of the Symp. Iron and Steel Pollution Abatement Techniques for 1980 (Washington, D.C.: U.S. EPA, 1980), pp. 577–606.

L.G. Evans and J.C. Hogan, “Recycling of EAF Dust by Direct Injection,” in Ref. 4, pp. 89–94.

S.E. James and C.O. Bounds, “Recycling Lead and Cadmium, as well as Zinc, from EAF Dust,” Lead-Zinc ’90, ed. T.S. Mackey and R.D. Prengaman (Warrendale, PA: TMS, 1990), p. 477.

T. Funahashi, A. Kaikake, and T. Sugiura, “Recent Development of Waelz Kiln Process for EAF Dust Treatment at Sumitomo Shisaka Works,” EPD Congress 1998, ed. B. Mishra (Warrendale, PA: TMS, 1998), pp. 487–496.

F. García-Carcedo et al., “Desarrollo de una tecnología más limpia para la obtención de ZnO a partir de residuos generados en la fabricación del acero,” Rev. Metal., 3 (May 1998), pp. 432–435.

C.O. Bounds and J.F. Pusateri, “EAF Dust Processing in the Gas-Fired Flame Reactor,” Lead-Zinc ’90, ed. T.S. Mackey and R.D. Prengaman (Warrendale, PA: TMS, 1990), pp. 511–528.

D. Pearson, Process and Fundamental Considerations of Selective Hydrometallurgical Systems (Littleton, CO: SME, 1981), pp. 153–168.

M.C. Jha and W.P.C. Duyvesteyn, “A Two-Stage Leaching Process for Selective Recovery of Zinc from Steel Plant Dusts,” Recycle and Secondary Recovery of Metals, ed. P.R. Taylor, H.Y. Sohn, and N. Jarrett (Warrendale, PA: TMS, 1985), pp. 143–157.

J. Frenay, S. Ferlay, and J. Hissell, “Zinc and Lead Recovery from EAF Dusts by Caustic Soda Process,” in Ref. 4, pp. 171–175.

J.G. Eacott et al., “Techno-Economic Feasibility of Zinc and Lead Recovery from Electric Arc Furnace Baghouse Dust,” CIM Bulletin, 77 (869) (September 1984), pp. 75–81.

M.L. Stamatovic and N.J. Themelis, “Recovery of Zinc from Ironmaking Dust by NaOH Leaching,” Extraction and Processing for the Treatment and Minimization of Wastes, ed. J. Hager et al. (Warrendale, PA: TMS, 1993), pp. 533–542.

M. Olper, “Zinc Extraction from EAF Dust with EZINEX Process,” Third Intl. Symp. Recycling of Metals and Engineered Matls., ed. P.B. Queneau and R.D. Peterson (Warrendale, PA: TMS, 1995), pp. 563–578.

F. Carranza et al. “Tratamiento Hidrometalúrgico de Residuos Sólidos Procedentes de Horno de Fundición de Arco Eléctrico (Polvos de Acería), V Congreso Internacional de Química de la ANQUE, Solid, Liquid and Gaseous Wastes: Their Best Destination (III) (1998).

Author information

Authors and Affiliations

Additional information

For more information, contact I. Palencia, University 41012 Seville, Spain; telephone 34-954-557-182; fax 34-954-557-134; e-mail inmapere@cica.es.

Rights and permissions

About this article

Cite this article

Palencia, I., Romero, R., Iglesias, N. et al. Recycling EAF dust leaching residue to the furnace: A simulation study. JOM 51, 28–32 (1999). https://doi.org/10.1007/s11837-999-0238-9

Issue Date:

DOI: https://doi.org/10.1007/s11837-999-0238-9