Abstract

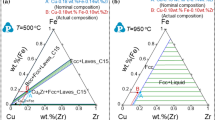

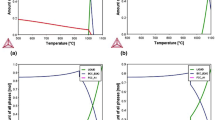

Alloys that combine the high electrical and thermal conductivity of copper with the low thermal expansivity and higher strength of Invar (Fe-36Ni), are of interest for a range of applications. In suitable Cu-Fe-Ni alloys, nearly pure copper equilibriates with an Invar-rich solid solution; casting such alloys invariably produces Invar-rich dendrites in a copper-rich solid solution. Two-phase alloys that combine the properties of copper and Invar can be produced by casting followed by suitable heat treatments. The overall composition controls the relative fractions of Invar and copper and the resulting trade-off between low thermal expansivity and high electrical conductivity. Analyses of phase equilibria and load transfer between ductile copper and Invar indicate that effective composites are only feasible for compositions between approximately 20 and 80 percent Invar.

Similar content being viewed by others

References

C. Zweben and K. Schmidt, Electronic Materials Handbook, Vol. 1: Packaging (Metals Park, OH: ASM, 1989), pp. 1129–1130.

J. Forster and W. Johnson, Metallurgical Branch, Texas Instruments, private communication, 12 June 1995.

C.R. Scorey and A.J. Moses (Paper presented at the 1995 TMS Annual Meeting, Las Vegas, NV, 1995).

M. Pecht et al., Quality Conformance and Qualification of Microelectronic Packages and Interconnects (New York: J. Wiley and Sons, 1994) pp. 300–301.

M. Shiga, Materials Science and Technology, A Comprehensive Treatment, vol. 3B, eds. R.W. Cahn, P. Haasen, and E.J. Kramer (Meinheim, Germany: VCH, 1994), pp. 159–210.

THERMOCALC, with SGTE Solutions and Substances Database (Royal Institute of Technology, Stockholm, Sweden).

Y.A. Chang et al., INCRA Monograph VI: The Metallurgy of Copper (New York: ICRA, 1979) pp. 467–477.

W. Köster and W. Dannöhl, Z. Metallk., 27 (1935), p. 220.

V. Daniel and H. Lipson, Proc. R. Soc., 182 (1942), p. 378.

M. Hillert, M. Cohen, and B.L. Averbach, Acta Metall., 9 (1961), p. 536.

E.P. Butler and G. Thomas, Acta Metall., 18 (1970), p. 347.

J. Cahn, Acta Metall., 10 (1962), p. 179.

W.F. Smith, Principles of Materials Science and Engineering, 3rd. ed. (New York: McGraw-Hill, 1996) p. 174.

Author information

Authors and Affiliations

Additional information

R.K. Jain will earn his B.S. in mechanical science at the University of Texas at Austin August.

For more information, contact R.D. Cottle, Center for Materials Science and Engineering, University of Texas at Austin, ETC 9.104, Austin, Texas 78712; cottle@mail.utexas.edu.

Rights and permissions

About this article

Cite this article

Cottle, R.D., Chen, X., Jain, R.K. et al. Designing low-thermal-expansivity, high-conductivity alloys in the Cu-Fe-Ni ternary system. JOM 50, 67–69 (1998). https://doi.org/10.1007/s11837-998-0132-x

Issue Date:

DOI: https://doi.org/10.1007/s11837-998-0132-x