Abstract

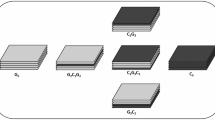

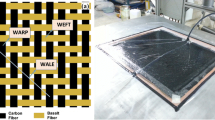

In pursuit of superior joint strengths in carbon fiber-reinforced plastics (CFRPs), this work employed T800 carbon fiber/epoxy prepreg combined with adhesive film as the interlayer, cured using microwave technology. Dielectric constants remain impervious to significant shifts during the microwave-induced curing of the T800 carbon fiber/epoxy prepreg and adhesive film. X-ray diffraction (XRD) and Fourier-transform infrared spectroscopy (FT-IR) confirmed that the cured products of varying layup thicknesses exhibited consistency, with the T800 carbon fiber/epoxy prepreg and the adhesive film all stemming from the same bisphenol A (BPA) resin system. Electron microscopy revealed similar bonding strengths across the five evaluated samples. Comprehensive assessments of static tensile and flexural behaviors were undertaken for diverse CFRP samples post-joining. Notably, a positive correlation between adhesive layer thickness and both tensile strength and three-point bending strength was observed. Specifically, Sample 5 manifested the peak tensile strength and three-point bending strength, registering at 258.16 MPa and 668.82 MPa, respectively. Contrastingly, Sample 2 boasted the maximal three-point bending modulus of 668.82 GPa, while Sample 3 achieved the zenith tensile modulus at 85.16 GPa. Based on observed experimental outcomes, bifurcated tensile and three-point bending failure models for the samples have been proposed.

Similar content being viewed by others

References

J. Frketic, T. Dickens, and S. Ramakrishnan, Addit. Manuf. 14, 69 (2017).

C. Soutis, Prog. Aerosp. Sci. 41, 143 (2005).

A. Al-Lami, P. Hilmer, and M. Sinapius, Aerosp. Sci. Technol. 79, 669 (2018).

M. Subhani, A. Globa, R. Al-Ameri, and J. Moloney, Constr. Build. Mater. 150, 480 (2017).

R. Kumar, P.K. Agrawal, and I. Singh, J. Manuf. Process. 31, 859 (2018).

J. Zhang, G. Lin, U. Vaidya, and H. Wang, Compos. B Eng. 250, 110463 (2023).

Y.F. Khalil, Sustain. Prod. Consump. 12, 16 (2017).

J.C. Williams and R.R. Boyer, Metals 10, 66 (2020).

H. Dutta, K. Debnath, and D.K. Sarma, Polym. Compos. 40, 4033 (2019).

V.K. Rangari, M.S. Bhuyan, and S. Jeelani, Compos. A Appl. Sci. Manuf. 42, 849 (2011).

A. Haque, M. Shamsuzzoha, F. Hussain, and D. Dean, J. Compos. Mater. 37, 1821 (2003).

S.C. Hendy and I.W.M. Brown, Curr. Appl. Phys. 8, 223 (2008).

M. Trihotri, U.K. Dwivedi, F.H. Khan, M.M. Malik, and M.S. Qureshi, J. Non-Cryst. Solids 421, 1 (2015).

A. Pramanik, A.K. Basak, Y. Dong, P.K. Sarker, M.S. Uddin, G. Littlefair, A.R. Dixit, and S. Chattopadhyaya, Compos. Pt. A-Appl. Sci. Manuf. 101, 1 (2017).

F. Lambiase and D.C. Ko, Mater. Des. 107, 341 (2016).

M. Mariam, M. Afendi, M.S.A. Majid, M.J.M. Ridzuan, and A.G. Gibson, Compos. Struct. 200, 647 (2018).

P. Galvez, J. Abenojar, and M.A. Martinez, Compos. Pt. B-Eng. 165, 1 (2019).

M.A. Karatas and H. Gokkaya, Defen. Technol. 14, 318 (2018).

G.D. Goh, V. Dikshit, A.P. Nagalingam, G.L. Goh, S. Agarwala, S.L. Sing, J. Wei, and W.Y. Yeong, Mater. Des. 137, 79 (2018).

D.F. Liu, Y.J. Tang, and W.L. Cong, Compos. Struct. 94, 1265 (2012).

D. Dolkun, H. Wang, H. Wang, and Y. Ke, Appl. Compos. Mater. 27, 811 (2020).

D. Abliz, Y.G. Duan, L. Steuernagel, L. Xie, D.C. Li, and G. Ziegmann, Polym. Polym. Compos. 21, 341 (2013).

M. Chen, E.J. Siochi, T.C. Ward, and J.E. McGrath, Polym. Eng. Sci. 33, 1092 (1993).

B.K. Rajeshwar, I. Jang, and C. Yi, Constr. Build. Mater. 218, 681 (2019).

C.E. Cruz-Gonzalez, J.D. Mosquera-Artamonov, S.D. Santillan, and H. Gamez-Cuatzin, Revista De Metalurgia 54, 66 (2018).

P. Silva-Bermudez, S. Muhl, and S.E. Rodil, Appl. Surf. Sci. 282, 351 (2013).

X.Y. Liu, J.C. Wu, J.J. Xi, and Z.Q. Yu, Materials 12, 66 (2019).

K.H. Chen, G.Z. Zhao, J. Chen, X.B. Zhu, and S.H. Guo, Materials 16, 15 (2023).

J. Peng and H. Xia, Microwave Metallurgy (Science Press, Beijing, 2017).

B. Sehar, A. Waris, and S.O. Gilani, Crystals 12(10), 1429 (2022).

Y.-C. Cheng, C.-M. Wu, and P.-C. Lin, Mod. Phys. Lett. B 34, 07 (2020).

J.Y. Deng, L. Xu, L.B. Zhang, J.H. Peng, S.H. Guo, J.H. Liu, and S. Koppala, Processes 7, 12 (2019).

M.B. Vazquez-Santos, E. Geissler, K. Laszlo, J.N. Rouzaud, A. Martinez-Alonso, and J.M.D. Tascon, J. Phys. Chem. C 116, 257 (2012).

S. Dai, Advanced Fiber Reinforced Composites (East China University of Science and Technology Press, Shanghai, 2013).

Acknowledgements

This work was supported by the China Petrochemical Corporation (Sinopec Group) (Grant Numbers: GFS21-L3-009, and 219025-2).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, X., Chen, K., Gao, L. et al. Microwave Heating and Curing of Joined Carbon Fiber Composites. JOM (2024). https://doi.org/10.1007/s11837-024-06629-9

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06629-9