Abstract

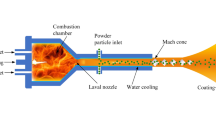

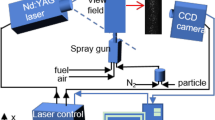

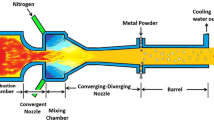

High-velocity oxygen fuel (HVOF) thermal spraying technology has been widely used to prepare anti-corrosion and wear-resistant coatings. In this study, the compressible turbulent flow, combustion reaction, and particle flight characteristics in a JP8000 spray gun were calculated. The turbulence models of realizable k–ε, RSM, and SST k–ω were analyzed and compared. Based on the realizable k–ε model, the effects of particles for incidence velocity, incidence angle, and shape on particle flight behavior during spraying are discussed in detail. The results show that the realizable k–ε model predicts that the surface pressure effect at the particle inlet is obvious and that the local turbulence intensity is relatively high. The combustion reaction predicted by the RSM model occurs relatively slowly, is concentrated in the back part of the combustion chamber, and takes into account the accumulation of oxygen concentration. When the particle incidence angle is − 45° and the injection velocity is 10–20 m/s, the flight path is closer to the gun axis, which is conducive to particle heating and acceleration. Particle morphology has a significant effect on flight behavior, particles with low shape factor should be selected for their large size, and particles with a high shape factor should be selected for their small size.

Similar content being viewed by others

References

H. Jafari, S. Emami, and Y. Mahmoudi, Appl. Therm. Eng. 111, 745 (2017).

M. Abbas, G.M. Smith, and P.R. Munroe, Surf. Coat. Technol. 394, 125909 (2020).

M. Abbas, G.M. Smith, and P.R. Munroe, Surf. Coat. Technol. 409, 126832 (2021).

J. Pan, S. Hu, L. Yang, K. Ding, and B. Ma, Mater. Des. 96, 370 (2016).

A.A. Abubakar, A.F.M. Akhtar, S.S. Akhtar, and J. Mostaghimi, J. Therm. Spray Technol. 28(3), 359 (2019).

G. Wang, Z. Huang, P. Xiao, and X. Zhu, J. Manuf. Process. 22, 34 (2016).

S.L. Liu, X.P. Zheng, and G.Q. Geng, Wear 269, 362 (2010).

S. Vijay, L. Wang, C. Lyphout, P. Nylen, and N. Markocsan, Appl. Surf. Sci. 493, 956 (2019).

E. Dongmo, M. Wenzelburger, and R. Gadow, Surf. Coat. Technol. 202, 4470 (2008).

J.S. Baik and Y.J. Kim, Surf. Coat. Technol. 202, 5457 (2008).

S. Kamnis, S. Gu, T.J. Lu, and C. Chen, Comput. Mater. Sci. 43, 1172 (2008).

H. Tabbara, S. Gu, and D.G. McCartney, Comput. Fluids 44, 358 (2011).

X. Wang, Q. Song, and Z. Yu, J. Therm. Spray Technol. 25, 441 (2015).

S. Emami, H. Jafari, and Y. Mahmoudi, J. Therm. Spray Technol. 28(3), 333 (2019).

C. Li, X. Gao, Y. Yang, X. Chen, and X. Han, Therm. Spray Technol 31(3), 585 (2022).

X. Gao, C. Li, Y. Xu, X. Chen, and X. Han, J. Therm. Spray Technol. 30(7), 1875 (2021).

H.R. Jiang, M.L. Wei, X.S. Ma, and T.C. Dong, J. Therm. Spray Technol. 28(6), 1146 (2019).

H. Tabbara and S. Gu, AlChE J. 58, 3533 (2012).

J. Yu, X. Liu, Y. Yu, Z. Li, S. Xu, H. Li, P. Liu, and L. Wang, J. Therm. Spray Technol. 31, 2448 (2022).

S. Gu and S. Kamnis, Chem. Eng. Process. 45, 246 (2005).

M.N. Khan and T. Shamim, Appl. Energ. 130, 853 (2014).

B.F. Magnussen and B.H. Hjertager, Nor. Inst. Technol. 16, 719 (1977).

B.F. Magnussen, B.H. Hjertager, J.G. Olsen, and D. Bhaduri, Central Mechan. Eng. Res. Inst. 17, 1383 (1979).

S. Kamnis and S. Gu, Chem. Eng. Sci. 61(16), 5427 (2006).

K. Kundu, P. Penko, S. Yang, 36th AIAA Aerospace Sciences Meeting and Exhibit (1998)

X. Zhao, C. Li, S. Li, X. Han, and P. Liu, Appl. Therm. Eng. 241, 122405 (2024).

X. Zhao, C. Li, S. Li, H. Jiang, and X. Han, Surf. Coat. Technol. 461, 129435 (2023).

M. Li and P.D. Christofides, Chem. Eng. Sci. 60(13), 3649 (2005).

M.N. Khan and T. Shamim, Appl. Energy 130, 853 (2014).

F. Liu, Z. Li, M. Fang, and H. Hou, Materials 14(3), 657 (2021).

S. Liu, H. Wu, S. Xie, M.P. Planche, D. Rivolet, M. Moliere, and H. Liao, Surf. Coat. Technol. 408, 126805 (2021).

L. Qiao, Y. Wu, S. Hong, J. Cheng, and Z. Wei, Surf. Coat. Technol. 366, 296 (2019).

M. Jadidi, S. Moghtaderenjad, and A. Dolatabadi, J. Therm. Spray Technol. 25(3), 451 (2016).

Funding

This work was supported by “Applied Basic Research Program of Liaoning Province” (2023JH2/101300226), and “Project for Graduate Education Reform and Technological Innovation and Entrepreneurship of University of Science and Technology Liaoning” (2023YJSCX02).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this study

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, S., Li, C., Liu, P. et al. Study of Turbulent Behavior and Particle Flight Characteristics Based on Different Turbulence Models During HVOF Spraying. JOM (2024). https://doi.org/10.1007/s11837-024-06617-z

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06617-z