Abstract

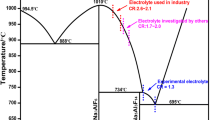

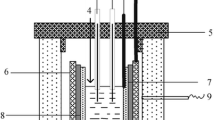

Currently, the development of oxygen-evolving anodes for eco-friendly technologies to produce important metals and alloys by electrolysis of molten salts seems to be an urgent task. To determine the degree of “inertness” of a particular anode material, data on the kinetics and mechanism of the anode process on an ideal material not subject to oxidation are required. In this connection, the anode process on gold in the low-temperature KF-AlF3-Al2O3 melt for electrolytic aluminum production was investigated in this work by cyclic and square-wave voltammetry methods. The influence of temperature (715 and 775°C) of the melt, the content of Al2O3 in it (from 0.1 to saturation), as well as the polarization rate (0.05–1 V s−1) on the kinetics and some features of the mechanism of the investigated process was determined. An assumption is made that oxygen release on gold without dissolution of the substrate takes place in the region of overvoltages from 0 to 0.8 V. It is shown that the process includes the stages of electrochemical adsorption and desorption of the intermediate product, the first of which is limited by the diffusion of electroactive anions to the anode.

Similar content being viewed by others

References

D. Yang, Sh. Jiang, Y. Liu, J. Chen, D. Wang, Yu. Zaikov, L. Wang, Zh. Chai, and W. Shi, J. Radioanal. Nucl. Chem. 332, 1377 https://doi.org/10.1007/s10967-023-08782-y (2023).

A. Galashev, K. Abramova, A. Vorobev, O. Rakhmanova, and Y. Zaikov, Electrochem. Mater. Technol. 2, 20232017 https://doi.org/10.15826/elmattech.2023.2.017 (2023).

A. Verma, A. Singh, and A. Colclasure, JOM 76, 1171 https://doi.org/10.1007/s11837-023-06274-8 (2024).

A. Demin, and D. Bronin, Electrochem. Mater. Technol. 2, 20232016 https://doi.org/10.15826/elmattech.2023.2.016 (2023).

W. Liu, D. Zhou, and Zh. Zhao, JOM 71, 2420 https://doi.org/10.1007/s11837-019-03487-8 (2019).

W. Gu, J. Diao, J. Wang, H. Li, and B. Xie, JOM 75, 1731 https://doi.org/10.1007/s11837-023-05757-y (2023).

L. Dion, L.I. Kiss, S. Poncsák, and Ch. Lagacé, JOM 68, 2472 https://doi.org/10.1007/s11837-016-2043-6 (2016).

J.W. Evans, JOM 59(5), 30 https://doi.org/10.1007/s11837-007-0020-9 (2007).

A.V. Mikhaylovskaya, A.D. Kotov, R. Yu Barkov, O.A. Yakovtseva, M.V. Glavatskikh, I.S. Loginova, and A.V. Pozdniakov, JOM 76, 1821 https://doi.org/10.1007/s11837-023-06214-6 (2024).

A. Du, L. Lattanzi, A.E. Jarfors, J. Zheng, K. Wang, and G. Yu, Crystals 13(12), 1621 https://doi.org/10.3390/cryst13121621 (2023).

A.S. Lebedev, V.E. Eremyashev, A.V. Suzdaltsev, and V.N. Anfilogov, Russ. Met. (Met.) 2020(6), 686 https://doi.org/10.1134/S0036029520060129 (2020).

I. Mohammad, M. Dupuis, P.D. Funkenbusch, and D.H. Kelley, JOM 74, 1908 https://doi.org/10.1007/s11837-022-05254-8 (2022).

A.Yu. Nikolaev, O.B. Pavlenko, A.V. Suzdaltsev, and Yu.P. Zaikov, J. Electrochem. Soc. 167(12), 126511 https://doi.org/10.1149/1945-7111/abb176 (2020).

Zh. Zhao, B. Gao, Y. Feng, Y. Huang, Zh. Wang, Zh. Shi, and X. Hu, JOM 69, 281 https://doi.org/10.1007/s11837-016-1999-6 (2017).

Y. Song, J. Peng, Y. Di, Y. Wang, and N. Feng, JOM 69, 2844 https://doi.org/10.1007/s11837-017-2615-0 (2017).

J. Liu, Sh. Wei, J.J.J. Chen, H. Wijayaratne, Zh. Wang, B. Gao, and M.P. Taylor, JOM 72, 253 https://doi.org/10.1007/s11837-019-03863-4 (2020).

O. Tkacheva, P. Arkhipov, and Yu. Zaykov, Electrochem. Commun. 110, 106624 https://doi.org/10.1016/j.elecom.2019.106624 (2020).

M. Lin, X. Hu, Zh. Shi, B. Gao, J. Yu, and Zh. Wang, JOM 72, 278 https://doi.org/10.1007/s11837-019-03882-1 (2020).

H. Yan, Z. Liu, W.I. Ma, L. Huang, C. Wang, and Y. Liu, JOM 72, 247 https://doi.org/10.1007/s11837-019-03909-7 (2020).

P.S. Pershin, A.V. Suzdaltsev, and Y.P. Zaikov, Russ. Met. (Met.) 2021(2), 213 https://doi.org/10.1134/S0036029521020191 (2021).

A. Yasinskiy, A. Suzdaltsev, S.K. Padamata, P. Polyakov, and Y. Zaikov, Light Met.. https://doi.org/10.1007/978-3-030-36408-3_85 (2020).

B.J. Welch, JOM 51(5), 24–28 https://doi.org/10.1007/s11837-999-0036-4 (1999).

X. Wu. Inert Anodes for Aluminum Electrolysis (Cham, Switzerland) (TMS, Springer Nature Switzerland AG) (2021). https://doi.org/10.1007/978-3-030-28913-3

S.K. Padamata, K. Singh, G.M. Haarberg, and G. Saevarsdottir, J. Electrochem. Soc. 170, 073501 https://doi.org/10.1149/1945-7111/ace332 (2023).

K. Singh, G. Gunnarsson, J.H. Magnusson, G.M. Haarberg, and G. Saevarsdottir, J. Electrochem. Soc. 170, 113507 https://doi.org/10.1149/1945-7111/ad0bae (2023).

E.S. Gorlanov, E.A. Mushihin, S.R. Schneider, and K.V. Kovalskaya, J. Electrochem. Soc. 170, 102501 https://doi.org/10.1149/1945-7111/acfac4 (2023).

J. Yang, W. Tao, L. Chen, J. He, Y. Zhang, J. Yu, and Zh. Wang, JOM 73, 3727 https://doi.org/10.1007/s11837-021-04849-x (2021).

A.V. Suzdaltsev, A.A. Filatov, A.Y. Nikolaev, A.A. Pankratov, N.G. Molchanova, and Y.P. Zaikov, Russ. Met. (Met.) 2018(2), 133 https://doi.org/10.1134/S0036029518020180 (2018).

K. Xie, Zh. Shi, J. Xu, X. Hu, B. Gao, and Zh. Wang, JOM 69, 1963 https://doi.org/10.1007/s11837-017-2478-4 (2017).

S.M. Treceño, A. Allanore, C.M. Bishop, A.T. Marshall, and M.J. Watson, JOM 73, 1899 https://doi.org/10.1007/s11837-021-04681-3 (2021).

A. Mukherjee, M.S. Khan, and R. Kumaresan, J. Electrochem. Soc. 170, 102505 https://doi.org/10.1149/1945-7111/ad02c2 (2023).

Y. Zaikov, V. Batukhtin, N. Shurov, and A. Suzdaltsev, Electrochem. Mater. Technol. 1, 20221007 https://doi.org/10.15826/elmattech.2022.1.007 (2022).

V.K. Mann, A.O. Gusev, and D.A. Simakov. Method of aluminum alloys production, Pat. RU2673597, priority 24.11.2016, published 28.11.2018.

A.V. Rudenko, A.A. Kataev, M.M. Neupokoeva, and O.Y. Tkacheva, Russ. Met. (Met.) 2023(2), 114 https://doi.org/10.1134/S0036029523020180 (2023).

S. Rolseth, H. Gudbrandsen, and J. Thonstad, ECS Trans. 50(11), 251 https://doi.org/10.1149/05011.0251ecst (2012).

V.N. Nekrasov, O.V. Limanovskaya, A.V. Suzdaltsev, A.P. Khramov, and Y.P. Zaikov, Russ. Met. (Metally) 2014(8), 664 https://doi.org/10.1134/S0036029514080084 (2014).

A. Suzdaltsev, and Yu. Zaikov, J. Electrochem. Soc. 170(5), 056506 https://doi.org/10.1149/1945-7111/acd1be (2023).

E.W. Dewing, and E.T. Van der Kouwe, J. Electrochem. Soc. 124, 58 https://doi.org/10.1149/1.2133245 (1977).

E.T. Turkdogan, Physical Chemistry of High Temperature Technology (New York) (Academic) 1st ed. (1980).

A. Suzdaltsev, A. Khramov, V. Kovrov, O. Limanovskaya, V. Nekrasov, and Y. Zaikov, Mat. Sci. Forum 844, 19 https://doi.org/10.4028/www.scientific.net/MSF.844.19 (2016).

S. Livingstone, Rhenium, Rhodium, Palladium, Osmium, Iridium and Platinum (Oxford) (Pergamon, Oxford, 1975).

Y. Wang, J. Peng, and Yu. Di, JOM 70, 1877 https://doi.org/10.1007/s11837-018-2858-4 (2018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nikolaev, A.Y., Suzdaltsev, A.V. & Zaikov, Y.P. Anode Process on Gold in KF-AlF3-Al2O3 Melt. JOM (2024). https://doi.org/10.1007/s11837-024-06597-0

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06597-0