Abstract

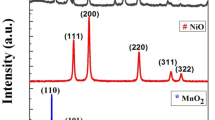

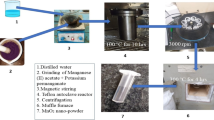

The development of an inexpensive, efficient, and sustainable material suitable for energy storage applications is the need of modern era. Due to their affordability, eco-friendliness, high efficiency, and unique electronic structure metal oxides are the favorable candidate for this purpose. Here, the most desirable MnO2/ZnO nanocomposites were fabricated via hydrothermal route. The successful fabrication of synthetic material was confirmed via X-ray diffraction, Fourier-transform infrared spectroscopy, scanning electron microscope, Raman spectroscopy, and X-ray photoelectron spectroscopy by analyzing the crystal structure, functionality, morphology, chemical property, and electronic properties. The electrochemical study was carried out in 1.0 M KOH (alkaline media) to assess the electrochemical performance of the fabricated composite materials for oxygen evolution reaction (OER) and supercapacitors. For this purpose, several various tests, like cyclic voltammetry, linear sweep voltammetry, galvanostatic charge discharge, and electrochemical impedance spectroscopy were performed. The electrochemical results revealed that the fabricated MnO2/ZnO nanocomposite has a Tafel slope and overpotential of 33.7 mV dec−1 and 274 mV, respectively. The small values of the Tafel slope and overpotential confirmed that our fabricated MnO2/ZnO nanocomposite is a potential candidate for OER. Moreover, the resultant MnO2/ZnO nanocomposite has a specific capacitance of 1038.3 F g−1 and a power density of 396.3 Wh kg−1. All these results confirmed that the fabricated MnO2/ZnO nanocomposite is a potential candidate for energy storage applications.

Similar content being viewed by others

Data Availability

The datasets generated during and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Q. Li, et al., Adv. Funct. Mater. 33(40), 2303466 (2023).

W. Kuang, et al., Acta Mater. 159, 16 (2018).

L. Sha, et al., Chem. Eng. J. 481, 148393 (2024).

J. Wang, et al., Sens. Actuators B Chem. 380, 133350 (2023).

Z. Huang, et al., J. Phys. Chem. Solids 167, 110746 (2022).

Z. Huang, et al., J. Phys. Chem. Solids 161, 110479 (2022).

G. Zhang, et al., ACS Appl. Electron. Mater. 6(2), 1339 (2024).

X. Zhao, et al., Appl. Surf. Sci. 642, 158639 (2024).

D. Chen and T. Savidge, Science 349(6251), 936 (2015).

S. Cherevko, et al., ChemCatChem 6(8), 2219 (2014).

X. Xie, et al., Adv. Funct. Mater. 32(21), 2110036 (2022).

J.K. Dombrovskis and A.E. Palmqvist, Fuel Cells 16(1), 4 (2016).

J.K. Nørskov, et al., J. Phys. Chem. B 108(46), 17886 (2004).

Z. Saleem, et al., Catalysts 10(4), 464 (2020).

C.-H. Li, et al., ACS Appl. Mater. Interfaces 15(29), 35459 (2023).

S. Yin, et al., Chem. Eng. J. 464, 142683 (2023).

Y. Yan, et al., J. Mater. Chem. A 4(45), 17587 (2016).

X. Li, et al., J. Mater. Chem. A 4(31), 11973 (2016).

L. Zhuang, et al., Angew. Chem. Int. Ed. 59(34), 14664 (2020).

S. Cherevko, et al., Catal. Today 262, 170 (2016).

Y. Du, et al., Chem. Eng. J. 476, 146605 (2023).

H. He, et al., Org. Lett. 25(38), 7014 (2023).

X. Zhang, et al., Adv. Energy Mater. 6(11), 1502588 (2016).

M. Wang, et al., Nat. Chem. 10(6), 667 (2018).

K. Zhang and R. Zou, Small 17(37), 2100129 (2021).

R. Siavash Moakhar, et al., Adv. Mater. 33(33), 2007285 (2021).

M. Parveen, et al., Appl. Nanosci. 12(5), 1643 (2022).

S. Xiong, et al., Electrochim. Acta 222, 999 (2016).

C. Liu, et al., Appl. Surf. Sci. 469, 276 (2019).

Y.-K. Hsu, Y.-C. Chen, and Y.-G. Lin, ACS Appl. Mater. Interfaces 7(25), 14157 (2015).

T. Zahra, et al., Int. J. Hydrogen Energy 46(37), 19347 (2021).

A. Tahir, et al., ACS Appl. Nano Mater. 6(3), 1631 (2023).

S. Mu, et al., Natl. Sci. Rev. 8(7), 178 (2021).

Q.-P. Ding, et al., J. Phys. Chem. C 112(48), 18846 (2008).

J. Jitputti, et al., J. Solid State Chem. 180(5), 1743 (2007).

M.Y. Rafiq, et al., J. Alloys Compd. 729, 1072 (2017).

E. Samuel, et al., ACS Sustain. Chem. Eng. 8(9), 3697 (2020).

Z. Liang, et al., Chin. J. Struct. Chem. 42(11), 100108 (2023).

M.A. Dar, et al., Mater. Today Proc. 66, 1689 (2022).

A.L. Tomas-Garcia, et al., Int. J. Electrochem. Sci. 9(2), 1016 (2014).

V.V. Kutwade, et al., J. Mater. Sci. Mater. Electron. 34(14), 1 (2023).

J. Huang, et al., J. Mater. Chem. A 8(48), 25465 (2020).

S. Zhang, et al., Catal. Commun. 113, 19 (2018).

X. Ye, et al., Nanoscale 13(35), 14854 (2021).

Y. Zhang, et al., Appl. Catal. B 257, 117899 (2019).

J. Sun, et al., Angew. Chem. Int. Ed. 60(35), 19435 (2021).

M.U. Nisa, et al., Fuel 321, 124086 (2022).

M. Tariq, et al., Int. J. Hydrogen Energy 45(35), 17287 (2020).

N.A. Khan, et al., Int. J. Hydrogen Energy 48(80), 31142 (2023).

B. Shabbir, et al., Fuel 341, 127638 (2023).

Y. Gao, et al., ACS Appl. Energy Mater. 3(1), 666 (2019).

K. Bera, et al., Inorg. Chem. 60(24), 19429 (2021).

C. Wang, et al., Int. J. Hydrogen Energy 46(17), 10356 (2021).

M. Boudart, Chem. Rev. 95(3), 661 (1995).

J. Ge, et al., Small 16(34), 2001856 (2020).

P. Anandhi, V.J. Senthil Kumar, and S. Harikrishnan, Funct. Mater. Lett. 12(05), 1950064 (2019).

M. Diantoro, et al., Int. J. Appl. Ceram. Technol. 20(4), 2077 (2023).

I. Hussain, et al., J. Mater. Chem. A 10(9), 4475 (2022).

S. Guan, et al., Adv. Funct. Mater. https://doi.org/10.1002/adfm.202314890 (2024).

M.S. Waheed, et al., Ceram. Int. 49(9), 13298 (2023).

R. Yang, et al., Adv. Mater. https://doi.org/10.1002/adma.202314247 (2024).

Acknowledgements

The Deanship of Scientific Research at King Khalid University is greatly appreciated for funding (R.G.P-1/356/44). The authors express their gratitude to Princess Nourah bint Abdulrahman University Researchers Supporting Project number (PNURSP2024R453), Princess Nourah bint Abdulrahman University, Riyadh, Saudi Arabia. A.M.A. Henaish thanks to Ministry of Science and Higher Education of the Russian Federation (Ural Federal University Program of Development within the Priority-2030 Program) for financial support.

Author information

Authors and Affiliations

Contributions

All the authors have done equal work.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Waheed, M.S., Alsalhi, S.A., Abdelmohsen, S.A.M. et al. Development of Novel Cube-Embedded MnO2/ZnO Nanocomposite for OER Activity and Supercapacitor Performance Evaluation. JOM (2024). https://doi.org/10.1007/s11837-024-06559-6

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06559-6