Abstract

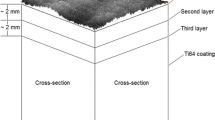

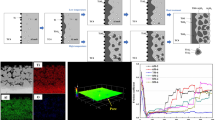

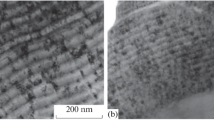

Ti-Al-Si coatings with excellent wear resistance were prepared on the surface of Ti plates by using a combination of hot-dip and thermal diffusion processes. The microstructure, growth kinetics and wear resistance mechanism of the coatings were investigated. The results show the coatings by hot dipping achieved good metallurgical bonding as well as presenting a multilayer phase structure, which was roughly divided into a diffusion layer containing Ti(Al, Si)3, a hybrid layer consisting of ι2-Ti3AlSi5 phase + Al, and the outermost Al-Si alloy layer. After thermal diffusion, the growth kinetics of the diffusion layer (Ti(Al, Si)3 phase) conformed to the Arrhenius relationship, and the fitted equation for the thickness of the reactive layer versus the diffusion parameter was: y = 2.7 × 10−3 exp(− 65,300/RT)t1/2. In addition, the hardness of the coating immersed for 15 min reached 740 HV, which was about 2.9 times that of the substrate, and the wear rate was only 50% of that of the substrate. The excellent wear resistance was attributed to the hard Ti(Al, Si)3 phase as well as the integrity of the coating.

Similar content being viewed by others

References

J. Wang, X. Ye, and Y. Li, Mater. Sci. Eng. A 869, 144788 (2023).

Y. Wang, S. Xiu, and S. Zhang, Surf. Coat. Technol. 417, 127211 (2021).

D. Li, Q. Le, X. Zhou, X. Li, C. Hu, R. Guo, T. Wang, P. Wang, and W. Hu, J. Magnes. Alloys 12, 1054 (2024).

S. Zhao, F. Meng, and B. Fan, Wear 512–513, 204532 (2023).

Y. Zhao, Z. Fan, and Q. Tan, Tribol. Int. 155, 106758 (2021).

M. Roostaei, A. Taghizadeh Tabrizi, and H. Aghajani, Tribol. Int. 191, 109129 (2024).

H. Wu, Y. Wu, and M. Yan, Opt. Laser Technol. 164, 109498 (2023).

C. Lin, X. Peng, and Y. Shi, J. Market. Res. 24, 1264 (2023).

D. Nolan, S.W. Huang, V. Leskovsek, and S. Braun, Surf. Coat. Technol. 200, 5698 (2006).

A. Taghizadeh Tabrizi, H. Aghajani, and F. Farhang Laleh, Surface Coat. Technol. 419, 127317 (2021).

A.T. Tabrizi, H. Aghajani, H. Saghafian, and F.F. Laleh, Tribol. Int. 155, 106772 (2021).

I. Vazirgiantzikis, S.L. George, and L. Pichon, Surf. Coat. Technol. 433, 128115 (2022).

C. Hu, Q. Le, and X. Zhou, Mater Charact 189, 111988 (2022).

Y. Zhang, J. Qie, and K. Cui, Ceram. Int. 46, 5223 (2020).

M. Windmann, A. Röttger, and W. Theisen, Surf. Coat. Technol. 246, 17 (2014).

F. Oukati Sadeq, M. Sharifitabar, and M. Shafiee Afarani, Surface Coat. Technol. 337, 349 (2018).

G.P. Cammarota, A. Casagrande, and G. Sambogna, Surf. Coat. Technol. 201, 230 (2006).

H.-P. Xiong, W. Mao, and Y.-H. Xie, Acta Mater. 52, 2605 (2004).

H.P. Xiong, Y.H. Xie, and W. Mao, Scr. Mater. 49, 1117 (2003).

T. Kubatík, M. Jáglová, E. Kalabisová, and V. Číhal, J. Alloy. Compd. 509, 5493 (2011).

K.M. Jasim, and E.S. Dwarakadasa, Wear 119, 119 (1987).

T. Gao, P. Li, Y. Li, and X. Liu, J. Alloy. Compd. 509, 8013 (2011).

S. Ma, N. Li, C. Zhang, and X. Wang, J. Alloy. Compd. 831, 154872 (2020).

Q. Luo, Q. Li, J.-Y. Zhang, S.-L. Chen, and K.-C. Chou, J. Alloy. Compd. 602, 58 (2014).

Y. Li, Q.-F. Gu, and Q. Luo, Mater. Des. 102, 78 (2016).

H. Aghajani, A. Taghizadeh Tabrizi, S. Arabpour Javadi, M.E. Taghizadeh Tabrizi, A. Homayouni, and S. Behrangi, Synth. Sinter. 1, 189 (2021).

S. Arabpour Javadi, S. Nozohour Hokmabadi, A. Taghizadeh Tabrizi, and H. Aghajani, Powder Metall. 64, 341 (2021).

X.T. Li, L.J. Huang, and S. Jiang, J. Alloy. Compd. 807, 151679 (2019).

J. Zhang, Y. Wang, and Z. Lü, Trans. Nonferrous Met. Soc. China 32, 524 (2022).

Z. Chao, and K. Dejun, Diam. Relat. Mater. 133, 109762 (2023).

Q. Wang, N. Kang, and M. El Mansori, Wear 523, 204790 (2023).

X. Xu, Z. Li, and W. Lai, Tribol. Int. 189, 108897 (2023).

M.V. Koricherla, T.B. Torgerson, and S.A. Alidokht, Wear 476, 203746 (2021).

X. Hao, H. Liu, and X. Zhang, Appl. Surf. Sci. 626, 157240 (2023).

Z.Y. Ren, Y.L. Hu, and Y. Tong, Tribol. Int. 182, 108366 (2023).

Y. Bian, L. Cao, and D. Zeng, Surf. Coat. Technol. 456, 129256 (2023).

J. Yuan, Q. Fan, and L. Yang, J. Market. Res. 20, 1 (2022).

S.P. Gupta, Mater Charact 49, 321 (2002).

Y. Wang, Z. Huang, and W. Hu, Mater Charact 178, 111298 (2021).

Acknowledgements

The authors are very grateful to the Nation Natural Science Foundation of China (Nos. 51974082, 51901037, 52274377) and the Fundamental Research Funds for the Central Universities (Grant number: N2202018).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhao, T., Le, Q., Wang, Y. et al. Enhancement in the Wear Resistance of Ti-Al-Si Coatings Fabricated by Hot Dipping. JOM (2024). https://doi.org/10.1007/s11837-024-06545-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06545-y