Abstract

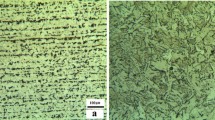

The metal inert gas (MIG) technique plays a vital role in enhancing the durability and lifespan of 20 steel under harsh operating conditions across various industries. A strong bond is crucial for preventing joint separation. Fe-based materials with appropriate Cr/C exhibit high compatibility with carbon steel bonding. Solid solutions can improve the situation faced by MIG-treated joints. In this work, weld joints were manufactured by MIG, and half of them were treated with a solid solution, and. after the analysis of microstructure and properties, it was found that the untreated fused zone (FZ) showed good forming quality with martensite, retained austenite, and had a carbide microstructure. The solid solution eliminated the retained austenite and exhibited an even hardness. The untreated heat-affected zone had a complex microstructure, dominating upper bainite, and discrepancy-shape ferrite. The untreated group's base material (BM) consisted of grain boundary martensite, ferrite, and pearlite in a matrix, while the solid-solution group's hardness was similar. Tensile tests revealed that the untreated group had a yield strength of 639 MPa, while the solid solution group gained 339 MPa. The untreated group in BM fractures was caused by grain boundary martensite, while the solid-solution group in FZ fractures was caused by α′ and carbides.

Similar content being viewed by others

References

J.J. Shen, R. Gonalves, Y.T. Choi, J.G. Lopes, J. Yang, N. Schell, H.S. Kim, and J.P. Oliveira, Scr. Mater. https://doi.org/10.1016/j.scriptamat.22.115053 (2022).

J.J. Shen, R. Gonalves, Y.T. Choi, J.G. Lopes, J. Yang, N. Schell, H.S. Kim, and J.P. Oliveira, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2022.144025 (2022).

S. Barzegar-Mohammadi, M. Haghpanahi, M. Zeinoddini, and R. Miresmaeili, J. Market. Res. 22, 3442 https://doi.org/10.1016/j.jmrt.2022.12.146 (2023).

W. Li, S. Qin, Y. Li, Y. Wang, P. Jiang, and W. Tong, J. Market. Res. 11, 1678 https://doi.org/10.1016/j.jmrt.2021.02.007 (2021).

J. Oñoro, J. Mater. Process. Technol. 180, 137 https://doi.org/10.1016/j.jmatprotec.2006.05.014 (2006).

Y. Wu, S. Xia, Q. Bai, W. Sun, B. Wang, Z. Zhou, and T. Liu, Vacuum. https://doi.org/10.1016/j.vacuum.2023.112270 (2023).

J.Y. Yun, G.S. Shin, D.H. Hur, W.S. Kang, C.H. Bae, and S.J. Kim, Wear 368–369, 124 https://doi.org/10.1016/j.wear.2016.09.005 (2016).

H. Fan, P. Liu, X. Guo, X. Wang, and Y. Wang, Int. J. Press. Vessels Pip. J. Press. Vessels Pip. https://doi.org/10.1016/j.ijpvp.2023.104918 (2023).

R. Bush, J. Gill, and J. Teakell, Jom 68, 3167–3173 https://doi.org/10.1007/s11837-016-2117-5 (2016).

L. Pan, C.T. Kwok, and K.H. Lo, J. Mater. Process. Technol. https://doi.org/10.1016/j.jmatprotec.2019.116448 (2020).

D.M. Aditya, H. Ardy, Y.S.F. Lantang, Y.S. Afrianti, N.F.F. Ilmi, and U.S. Pasaribu, Heliyon 9, e14109 https://doi.org/10.1016/j.heliyon.2023.e14109 (2023).

T. He, L. Wang, F. Hu, W. Zhou, Z. Zhang, and K. Wu, J. Market. Res. 22, 2690 https://doi.org/10.1016/j.jmrt.2022.12.092 (2023).

Q. Luo, J. Li, Q. Yan, W. Li, Y. Gao, M. Kitchen, L. Bowen, N. Farmilo, and Y. Ding, Wear. https://doi.org/10.1016/j.wear.2021.203732 (2021).

L. Raami, T. Varis, K. Valtonen, M. Wendler, O. Volkova, and P. Peura, Wear. https://doi.org/10.1016/j.wear.2023.204897 (2023).

X.X. Dong, and Y.F. Shen, Mater. Sci. Eng. A. Sci. Eng. A. https://doi.org/10.1016/j.msea.2022.143737 (2022).

L. Wang, Y. Ding, Q. Lu, Z. Guo, Y. Liu, and Z. Cui, Corros. Commun. 11, 1 https://doi.org/10.1016/j.corcom.2022.08.005 (2023).

Y.C. Li, W.J. Zhu, L.L. Sun, and L.Y. Li, Int. J. Electrochem. Sci. J. Electrochem. Sci. https://doi.org/10.1016/j.ijoes.2023.100295 (2023).

E. Cabrol, C. Boher, V. Vidal, F. Rezaï-Aria, and F. Touratier, Wear 426–427, 996 https://doi.org/10.1016/j.wear.2019.01.091 (2019).

Q. Yang, and J.L. Luo, Mater. Sci. Eng. A 288, 75 https://doi.org/10.1016/s0921-5093(00)00833-9 (2000).

Y. Tian, K. Chadha, S.H. Kim, and C. Aranas, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2021.140801 (2021).

Z. Wang, S. Xu, Q. Sui, J. Wang, H. Wen, T. Xiao, Q. Yuan, S. Mao, B. Yuan, Y. Wu, and J. Liu, Surf. Coat. Technol.. Coat. Technol. https://doi.org/10.1016/j.surfcoat.2023.129474 (2023).

F. Khorasani, R. Jamaati, and H. Jamshidi Aval, Mater. Chem. Phys.. Chem. Phys. https://doi.org/10.1016/j.matchemphys.2023.128246 (2023).

H.V. Ribeiro, M.S.F. Lima, J.B. Marcomini, F.C. Pinto, and C.A.R.P. Baptista, J. Mater. Eng. Perform. 31, 7686 https://doi.org/10.1007/s11665-022-06795-4 (2022).

J. Shen, P. Agrawal, T.A. Rodrigues, J.G. Lopes, N. Schell, J. He, Z. Zeng, R.S. Mishra, and J.P. Oliveira, Mater. Sci. Eng. A. Sci. Eng. A. https://doi.org/10.1016/j.msea.2023.144722 (2023).

K.E. Easterling, Mater. Sci. Eng. 65, 191 https://doi.org/10.1016/0025-5416(84)90212-x (1984).

A. Hamada, A. Khosravifard, M. Ali, S. Ghosh, M. Jaskari, M. Hietala, A. Järvenpää, and M. Newishy, Mater. Sci. Eng. A. Sci. Eng. A. https://doi.org/10.1016/j.msea.2023.145442 (2023).

C. Pandey, M.M. Mahapatra, P. Kumar, N. Saini, J.G. Thakre, R.S. Vidyarthy, and H.K. Narang, Arch. Civ. Mech. Eng. 18, 713 https://doi.org/10.1016/j.acme.2017.12.002 (2018).

L. Zhao, S. Wei, D. Wu, D. Gao, and S. Lu, J. Mater. Sci. Technol. 57, 33 https://doi.org/10.1016/j.jmst.2020.02.085 (2020).

C. Wang, T.G. Liu, P. Zhu, Y.H. Lu, and T. Shoji, Mater. Sci. Eng. A. Sci. Eng. A. https://doi.org/10.1016/j.msea.2020.140006 (2020).

A. Evangelou, R. Stylianou, A. Loizou, D. Kim, A. Liang, P. Reed, G. Constantinides, and T. Kyratsi, J. Alloys Metallurg. Syst. https://doi.org/10.1016/j.jalmes.2023.100027 (2023).

T. Li, S. Yan, D. An, X. Li, and J. Chen, J. Mater. Process. Technol. https://doi.org/10.1016/j.jmatprotec.2022.117632 (2022).

H. Qin, Z. Bi, H. Yu, G. Feng, J. Du, and J. Zhang, J. Alloys Compd. 740, 997–1006 https://doi.org/10.1016/j.jallcom.2018.01.030 (2018).

Y. Han, S. Zhong, C. Peng, L. Tian, Y. Sun, L. Zhao, and L. Xu, Int. J. Fatigue J. Fatigue. https://doi.org/10.1016/j.ijfatigue.2022.107156 (2022).

J. Liu, P. Yu, P. Chen, S. Chen, R. Lewis, Z. Xu, P. Li, and C. He, Eng. Fail. Anal. Fail. Anal. https://doi.org/10.1016/j.engfailanal.2023.107326 (2023).

P. Sharma, D.K. Dwivedi, and G. Sharma, Mater. Today Proc. https://doi.org/10.1016/j.matpr.2023.08.327 (2023).

X. Gao, X. Lin, T. Guo, L. Xu, Y. Han, B. Jiang, X. Mei, Q. Peng, and L. Qiao, J. Mater. Sci. Technol. 170, 140 https://doi.org/10.1016/j.jmst.2023.06.030 (2024).

D. Zhao, F. Liu, Y.-B. Tan, W. Shi, and S. Xiang, J. Market. Res. 26, 71 https://doi.org/10.1016/j.jmrt.2023.07.202 (2023).

J. Li, Y. Ni, H. Wang, and J. Mei, Nanoscale Res. Lett. 5, 420 https://doi.org/10.1007/s11671-009-9500-x (2009).

C. Wang, Y. Yu, J. Yu, Y. Zhang, Y. Zhao, and Q. Yuan, J. Manuf. Process. 50, 183 https://doi.org/10.1016/j.jmapro.2019.12.015 (2020).

M.P. Prabakaran, and G.R. Kannan, Int. J. Press. Vessels Pip. J. Press. Vessels Pip. https://doi.org/10.1016/j.ijpvp.2021.104322 (2021).

J. Abraham Mathews, J. Sietsma, R.H. Petrov, and M.J. Santofimia, J. Mater. Res. Technol. 25, 5325 https://doi.org/10.1016/j.jmrt.2023.06.270 (2023).

G. Dak, S. Sirohi, and C. Pandey, Int. J. Press. Vessels Pip. J. Press. Vessels Pip. https://doi.org/10.1016/j.ijpvp.2022.104629 (2022).

D.R. Pissanti, A. Scheid, L.F. Kanan, G. Dalpiaz, and C.E.F. Kwietniewski, Mater. Des. 162, 198 https://doi.org/10.1016/j.matdes.2018.11.046 (2019).

A. Sharma, D. Kant Verma, and S. Kumaran, Mater. Today Proc. 5, 8049 https://doi.org/10.1016/j.matpr.2017.11.490 (2018).

J. Ren, C. Li, Y. Han, E. Li, C. Gao, and C. Qiu, Mater. Sci. Eng. A. Sci. Eng. A. https://doi.org/10.1016/j.msea.2021.141080 (2021).

Z. Zhu, X. Ma, C. Wang, G. Mi, and S. Zheng, Mater. Des. https://doi.org/10.1016/j.matdes.2020.108893 (2020).

K. Yvell, T.M. Grehk, and G. Engberg, Mater Charact 122, 14–21 https://doi.org/10.1016/j.matchar.2016.10.017 (2016).

X.J. Sun, S.F. Yuan, Z.J. Xie, L.L. Dong, C.J. Shang, and R.D.K. Misra, Mater. Sci. Eng. A 689, 212–219 https://doi.org/10.1016/j.msea.2017.02.058 (2017).

B. Gao, L. Wang, Y. Liu, J. Liu, L. Xiao, Y. Sui, W. Sun, X. Chen, and H. Zhou, Mater. Sci. Eng. A. Sci. Eng. A. https://doi.org/10.1016/j.msea.2023.145370 (2023).

Z. Wang, and M.X. Huang, Int. J. Plast. J. Plast. https://doi.org/10.1016/j.ijplas.2020.102851 (2020).

Acknowledgements

This research was supported by the National Natural Science Foundation of China (51974091), the Hainan Province Science and Technology Special Fund (ZDYF2023090), Hainan Province Science and Technology Innovation Joint Project (2021CXLH0001), the Natural Science Foundation of Heilongjiang Province (LH2023E016) and the Youth Science Fund and Research Startup Fund of Northeast Petroleum University (2020QNL-09).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, W., Wang, Y., Zhou, J. et al. Bonding Strength of 12Cr-0.4C/Low Carbon Steel (LCS) Weld Joint After Solid Solution Heat Treatment. JOM (2024). https://doi.org/10.1007/s11837-024-06506-5

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11837-024-06506-5