Abstract

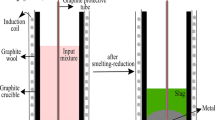

High iron bauxite (IRB), red mud (RM), and fly ash (FA) are resources rich in iron and alumina, yet there are no effective methods of recovering and utilizing them. In this paper, a new reduction smelting technology for the extraction of iron and alumina from IRB, RM, and FA is proposed based on the technology platform of “Slag Metallurgy, Mineral Recycling, and Resource Recovery”. For the first time, molten steel slag (SS) was used in the alumina extraction process, which not only recovered the heat resource and iron from SS but also recycled the activated calcium oxide. The phase evolution and composition during the reduction smelting process were analyzed based on the phase diagram of the CaO-Al2O3-SiO2 system, and the composition triangle was determined to be C2S-C12A7-CA. Experiments were carried out to test the raw materials and formulations supplied by different manufacturers, and the alumina extraction rate reached 85% in all cases, while the iron recovery rate reached 95%. This proposed method promotes the sustainable use of energy and resources and has a promising future for industrial applications.

Similar content being viewed by others

References

Y. Zhang, Y. Qi, and J. Li. https://doi.org/10.5772/intechopen.78789 (2018)

N. Papassiopi, K. Vaxevanidou, and I. Paspaliaris, Miner. Eng. 23, 25 https://doi.org/10.1016/j.mineng.2009.09.005 (2010).

C.A. Pickles, T. Lu, and B. Chambers, J. Forster Can. Metall. Q. 51, 424 https://doi.org/10.1179/1879139512y.0000000038 (2012).

J. Ding, S.H. Ma, S. Shen, Z.L. Xie, S.L. Zheng, and Y. Zhang, Waste Manag. 60, 375 https://doi.org/10.1016/j.wasman.2016.06.009 (2017).

H. Wen, Y. Wu, Y. Wang, L. Li, and X. Ma, J. Cryst. Growth 614, 127215 https://doi.org/10.1016/j.jcrysgro.2023.127215 (2023).

G. Power, M. Graefe, and C. Klauber, Hydrometallurgy 108, 33 https://doi.org/10.1016/j.hydromet.2011.02.006 (2011).

X. Li, Z. Yang, S. Yang, K. Zhang, and J. Chang, J. Environ. Manag. 344, 118616 https://doi.org/10.1016/j.jenvman.2023.118616 (2023).

F. Lyu, Y. Hu, L. Wang, and W. Sun, J. Hazard. Mater. 403, 123671 https://doi.org/10.1016/j.jhazmat.2020.123671 (2021).

G. Zhou, Y. Wang, T. Qi, Q. Zhou, G. Liu, Z. Peng, and X. Li, J. Environ. Chem. Eng. 11, 109433 https://doi.org/10.1016/j.jece.2023.109433 (2023).

T.R. Zonouz, B. Rezai, Z. Bahri, and A.A. Jahromi, J. Sustain. Metall. 9, 511 https://doi.org/10.1007/s40831-023-00661-w (2023).

G.N. Banerjee, B.R. Reddy, and R.B. Rao, Trans. Ind. Inst. Met. 53, 527 (2000).

Z. Liu, M. Chu, Z. Wang, W. Zhao, and J. Tang, High Temp. Mater. Process. 36, 79 https://doi.org/10.1515/htmp-2015-0005 (2017).

S. Yuan, R. Wang, H. Zhang, Y. Li, L. Liu, and Y. Fu, Sustainability 14, 13787 https://doi.org/10.3390/su142113787 (2022).

F. Gao, J. Zhang, X. Deng, K. Wang, C. He, X. Li, and Y. Wei, Jom 71, 2936 https://doi.org/10.1007/s11837-018-3311-4 (2019).

S. Agrawal, V. Rayapudi, and N. Dhawan, Miner. Eng. 132, 202 https://doi.org/10.1016/j.mineng.2018.12.012 (2019).

G. Lu, T. Zhang, X. Wang, X. Zhang, Y. Liu, Q. Zhao, and Z. Dou, J. Cent. South Univ. 21, 2168 https://doi.org/10.1007/s11771-014-2167-1 (2014).

Q. Long, J. Li, C. Chen, Y. Lan, and G. Wei, J. Iron. Steel Res. Int. 27, 310 https://doi.org/10.1007/s42243-019-00360-5 (2020).

Y. Zhang, Q. Gao, J. Zhao, M. Li, and Y. Qi, Minerals 9, 223 https://doi.org/10.3390/min9040223 (2019).

Y. Zhang, W. Lu, Y. Qi, and Z. Zou, Int. J. Miner. Metall. Mater. 23, 881 https://doi.org/10.1007/s12613-016-1303-3 (2016).

A. Lazou, L. Kolbeinsen, and J. Safarian, Materials 14, 7740 https://doi.org/10.3390/ma14247740 (2021).

K. Wang, Y. Liu, X. Li, Z. Dou, G. Lu, and T.A. Zhang. In: Eskin, D. (eds) Light Metals 2022. The Minerals, Metals & Materials Series. Springer, Cham. 41–47, (2022). https://doi.org/10.1007/978-3-030-92529-1_6

M.S. Archambo and S.K. Kawatra, Metall. Rev. 42, 222 https://doi.org/10.1080/08827508.2020.1720982 (2021).

Y. Ma, J.B. Pettersen, A. Preveniou, and A. Kladis, J. Clean. Prod. 366, 1 https://doi.org/10.1016/j.jclepro.2022.132807 (2022).

L. Zhang, Y. Zhang, and X. Zhou. Shenyang, CN112707424A[P]. 2021-04-27

H. Sun, B. Wang, J. Zhang, S. Zong, and J. Liu, Trans. Nonferrous Met. Soc. 25, 1334 https://doi.org/10.1016/s1003-6326(15)63732-3 (2015).

M. Kowalski, P. J. Spencer, and D. Neutschutz: Slag Atlas, ed. by VDEh, Verlag Stahleisen GmbH, Düsseldorf, Germany, 105 (1995).

Q. Shu, Y. Wang, J. Li, Y. Liu, P. Li, and K. Chou, ISIJ Int. 55, 2297 https://doi.org/10.2355/isijinternational.ISIJINT-2015-211 (2015).

M.K. Kar and J. Safarian, Processes 11, 137 https://doi.org/10.3390/pr11010137 (2023).

H. Wang, C. Liu, H.-W. Xing, J.-H. Wu, W.-L. Lin, S. Li, G.-H. Ding, and Y.-Z. Zhang, J. Iron. Steel Res. Int. 29, 783 https://doi.org/10.1007/s42243-021-00641-y (2022).

Acknowledgements

The authors are grateful for the financial support from the National Science and Technology Support Program of China (No. 2015BAB18B00) and the Key Research and Development Program of Hebei Province (20311008D).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wu, Y., Zhang, Y., Xu, S. et al. Recovery of Iron and Alumina from Iron-Rich Bauxite, Red Mud, and Fly Ash by Reduction Smelting with Steel Slag. JOM 76, 2457–2467 (2024). https://doi.org/10.1007/s11837-024-06487-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06487-5