Abstract

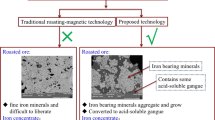

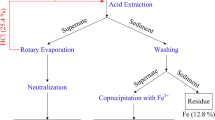

Iron ore tailings (IOTs) are an important solid waste in the mining industry, which can pollute the environment and endanger human health. However, the disposal and high value-added utilization of iron tailings have always been a challenge. Notably, superconducting high-gradient magnetic separation (S-HGMS) technology is a promising technology in mineral processing with the advantages of low carbon, green, high efficiency, and easy operation. This study used S-HGMS technology to separate and purify SiO2 concentrate from IOTs. Under the optimal conditions of magnetic flow ratio of 0.038 T s/m for the first magnetic separation, 0.085 T s/m for the second, pulp flow rate of 0.5 L/min, and pulp concentration of 50 g/L, increasing the SiO2 content from initial 61.38% to 95.23%, SiO2 recovery reached 38.51%. After the S-HGMS process, weak and non-magnetic particles realized effective separation, which created the conditions for the subsequent processing of SiO2 concentrate into high-purity silica. S-HGMS technology was used to extract SiO2 particles from IOTs, improving the utilization value of the tailings. This study provides an efficient and eco-friendly research direction for the industrial application of IOTs.

Similar content being viewed by others

References

K. Wang, S. Liu, K. Liu, M. Dan, X. Ji, Y. Lu, and Y. Xing, Environ. Sci. Technol. 57, 11510 https://doi.org/10.1021/acs.est.3c02624 (2023).

Y. Li, S. Li, X. Pan, X. Zhao, and P. Guo, J. Environ. Manag. 339, 117932 https://doi.org/10.1016/j.jenvman.2023.117932 (2023).

X. Han, F. Wang, Y. Zhao, J. Meng, G. Tian, L. Wang, and J. Liang, Environ. Chem. Lett. 21, 1005 https://doi.org/10.1007/s10311-022-01541-7 (2023).

T.S.W. Sá, S. Oda, V.K.C.B.L. Machado, and R.D. Toledo Filho, Constr. Build. Mater. 342, 128072 https://doi.org/10.1016/j.conbuildmat.2022.128072 (2022).

R.B. Saldanha, A.M.L. Caicedo, M.T. de Araújo, H.C. Scheuermann Filho, C.J. Moncaleano, J.P.S. Silva, and N.C. Consoli, Constr. Build. Mater. 365, 130008 https://doi.org/10.1016/j.conbuildmat.2022.130008 (2023).

N. Zhang, B. Tang, and X. Liu, Constr. Build. Mater. 288, 123022 https://doi.org/10.1016/j.conbuildmat.2021.123022 (2021).

F. Han, L. Li, S. Song, and J. Liu, Powder Technol. 315, 322 https://doi.org/10.1016/j.powtec.2017.04.022 (2017).

A.P. Wolff, G.M. Da Costa, and F. De Castro Dutra, Miner. Process. Extr. Metall. Rev. 32, 47 https://doi.org/10.1080/08827508.2010.530718 (2011).

H. Kobayashi, J. Garnier, D.S. Mulholland, C. Quantin, F. Haurine, M. Tonha, C. Joko, D. Olivetti, R. Freydier, P. Seyler, J.M. Martinez, and H.L. Roig, J. Hazard. Mater. 448, 130828 https://doi.org/10.1016/j.jhazmat.2023.130828 (2023).

G. Yao, Q. Wang, Y. Su, J. Wang, J. Qiu, and X. Lyu, Miner. Eng. 145, 106068 https://doi.org/10.1016/j.mineng.2019.106068 (2020).

K. Islam and S. Murakami, Glob. Environ. Change 70, 102361 https://doi.org/10.1016/j.gloenvcha.2021.102361 (2021).

W. Chen, S. Yin, G. Zhou, Z. Li, and Q. Song, J. Clean. Prod. 332, 130129 https://doi.org/10.1016/j.jclepro.2021.130129 (2022).

J. Zhao, K. Ni, Y. Su, and Y. Shi, Constr. Build. Mater. 286, 122968 https://doi.org/10.1016/j.conbuildmat.2021.122968 (2021).

Y.-H. Cheng, B.-Q. Tong, X.-H. Sun, and J.-Y. Zhang, Environ. Sci. Pollut. Res. 29, 73326 https://doi.org/10.1007/s11356-022-20964-x (2022).

S. Bai, G. Tian, L. Gong, Q. Tang, J. Meng, X. Duan, and J. Liang, Chem. Eng. Res. Des. 159, 543 https://doi.org/10.1016/j.cherd.2020.04.038 (2020).

J.M. Franco de Carvalho, K. Defáveri, J.C. Mendes, W. Schmidt, H.-C. Kühne, and R.A.F. Peixoto, Constr. Build. Mater. 272, 121640 https://doi.org/10.1016/j.conbuildmat.2020.121640 (2021).

K. Wang, Y. Liu, Z. Dou, G. Lu, X. Li, and T.-A. Zhang, JOM 74, 2750 https://doi.org/10.1007/s11837-022-05264-6 (2022).

Y. Zhang, L. Wang, Y. Duan, B. Liu, and J. Liang, Ceram. Int. 48, 11709 https://doi.org/10.1016/j.ceramint.2022.01.029 (2022).

C. Lu, H. Yang, J. Wang, Q. Tan, and L. Fu, Sci. Total. Environ. 736, 139483 https://doi.org/10.1016/j.scitotenv.2020.139483 (2020).

Z. Wei, Y. Jia, S. Wang, Z. Li, Y. Li, X. Wang, and Y. Gao, J. Clean. Prod. 335, 130318 https://doi.org/10.1016/j.jclepro.2021.130318 (2022).

S.S. Sarathchandra, Z. Rengel, and Z.M. Solaiman, Chemosphere 288, 132573 https://doi.org/10.1016/j.chemosphere.2021.132573 (2022).

Q. Yi, S.L. Wu, G. Southam, L. Robertson, F. You, Y.J. Liu, S.C. Wang, N. Saha, R. Webb, J. Wykes, T.S. Chan, Y.R. Lu, and L.B. Huang, Environ. Sci. Technol. 55, 8020 https://doi.org/10.1021/acs.est.1c00848 (2021).

S. Yuan, H. Ding, R. Wang, Q. Zhang, Y. Li, and P. Gao, Adv. Powder Technol. 33, 103643 https://doi.org/10.1016/j.apt.2022.103643 (2022).

A.D. Bas, Miner. Eng. 161, 106739 https://doi.org/10.1016/j.mineng.2020.106739 (2021).

R. Hossain and V. Sahajwalla, J. Clean. Prod. 316, 128344 https://doi.org/10.1016/j.jclepro.2021.128344 (2021).

Y. Zhang, K. Wang, G. Jia, J. Li, H. Wang, and Y. Tian, J. Alloy. Compd. 860, 157914 https://doi.org/10.1016/j.jallcom.2020.157914 (2021).

M. Lin, Z. Liu, Y. Wei, B. Liu, Y. Meng, H. Qiu, S. Lei, X. Zhang, and Y. Li, Min. Metall. Explor. 37, 1627 https://doi.org/10.1007/s42461-020-00247-0 (2020).

J.-S. Li, X.-X. Li, Q. Shen, Z.-Z. Zhang, and F.-H. Du, Environ. Sci. Technol. 44, 7673 https://doi.org/10.1021/es101104c (2010).

M. Lin, Z. Pei, and S. Lei, Minerals. https://doi.org/10.3390/min7090161 (2017).

A. Tuncuk and A. Akcil, Int. J. Miner. Process. 153, 44 https://doi.org/10.1016/j.minpro.2016.05.021 (2016).

H. Zhang, W. Chai, and Y. Cao, Appl. Surf. Sci. 576, 151834 https://doi.org/10.1016/j.apsusc.2021.151834 (2022).

X.N. Bu, G. Evans, G.Y. Xie, Y.L. Peng, Z.G. Zhang, C. Ni, and L.H. Ge, Appl. Clay Sci. 143, 437 https://doi.org/10.1016/j.clay.2017.04.020 (2017).

T.S. Qiu, X. Huang, and X.L. Yang, JOM 68, 548 https://doi.org/10.1007/s11837-015-1726-8 (2016).

Y.R. Chen, X.N. Bu, V.N.T. Truong, Y.L. Peng, and G.Y. Xie, Miner. Eng. 141, 105845 https://doi.org/10.1016/j.mineng.2019.105845 (2019).

V. Nunna, S.P. Suthers, M.I. Pownceby, and G.J. Sparrow, Miner. Process. Extr. Metall. Rev. 43, 1049 https://doi.org/10.1080/08827508.2021.2003353 (2022).

Q. Cheng, G. Mei, W. Xu, and Q. Yuan, Miner. Eng. 180, 107491 https://doi.org/10.1016/j.mineng.2022.107491 (2022).

J.X. Gao, Z. Tong, X.N. Bu, M. Bilal, Y. Hu, C. Ni, and G.Y. Xie, Fuel 337, 127145 https://doi.org/10.1016/j.fuel.2022.127145 (2023).

L.C. Moura, F.P. André, H. Miceli, R. Neumann, and L.M. Tavares, Miner. Process. Extr. Metall. Rev. 40, 333 https://doi.org/10.1080/08827508.2019.1643341 (2019).

Y. Li, S. Li, B. Hu, X. Zhao, and P. Guo, Sep. Purif. Technol. 285, 120372 https://doi.org/10.1016/j.seppur.2021.120372 (2022).

T. Ohara, H. Kumakura, and H. Wada, Physica C 357–360, 1272 https://doi.org/10.1016/S0921-4534(01)00530-5 (2001).

C. Yang, S. Li, C. Zhang, J. Bai, and Z. Guo, Miner. Process. Extr. Metall. Rev. 39, 44 https://doi.org/10.1080/08827508.2017.1324439 (2018).

L. Chen, T. Xiong, D. Xiong, R. Yang, Y. Peng, Y. Shao, J. Xu, and J. Zeng, Miner. Eng. 170, 106967 https://doi.org/10.1016/j.mineng.2021.106967 (2021).

L. Chen, W. Liu, J. Zeng, and P. Ren, Powder Technol. 313, 54 https://doi.org/10.1016/j.powtec.2017.03.011 (2017).

X.F. Zhang, X.M. Tan, Y.J. Yi, W.Z. Liu, and C. Li, JOM 69, 2352 https://doi.org/10.1007/s11837-017-2521-5 (2017).

J. Xu, D. Xiong, S. Song, and L. Chen, Results Phys. 10, 837 https://doi.org/10.1016/j.rinp.2018.07.027 (2018).

J. Zeng, L. Chen, R. Yang, X. Tong, P. Ren, and Y. Zheng, Int. J. Miner. Process. 168, 48 https://doi.org/10.1016/j.minpro.2017.09.005 (2017).

J. Xu, J. Chen, X. Ren, T. Xiong, K. Liu, and S. Song, Sep. Sci. Technol. 57, 484 https://doi.org/10.1080/01496395.2021.1900250 (2022).

Z. Yuan, X. Zhao, J. Lu, H. Lv, and L. Li, Int. J. Min. Sci. Technol. 31, 1043 https://doi.org/10.1016/j.ijmst.2021.10.011 (2021).

F. Mishima, S. Takeda, M. Fukushima, and S. Nishijima, Phys. C-Supercond. Appl. 463, 1302 https://doi.org/10.1016/j.physc.2007.04.304 (2007).

X. Zheng, Y. Wang, and D. Lu, Miner. Eng. 79, 94 https://doi.org/10.1016/j.mineng.2015.06.004 (2015).

Y.K. Li, S.Q. Li, X.D. Pan, X. Zhao, P.H. Guo, and Z.K. Zhao, Powder Technol. 424, 118523 https://doi.org/10.1016/j.powtec.2023.118523 (2023).

Y.K. Li, S.Q. Li, X.D. Pan, X. Zhao, and P.H. Guo, Sep. Sci. Technol. 58, 822 https://doi.org/10.1080/01496395.2022.2151471 (2023).

G. Yang, Y. Deng, H. Ding, Z. Lin, Y. Shao, and Y. Wang, Appl. Clay Sci. 111, 61 https://doi.org/10.1016/j.clay.2015.04.005 (2015).

E. Larsen and R.A. Kleiv, Miner. Eng. 98, 49 https://doi.org/10.1016/j.mineng.2016.07.021 (2016).

K.I. Vatalis, G. Charalambides, and N.P. Benetis, Procedia Econ. Finance 24, 734 https://doi.org/10.1016/S2212-5671(15)00688-7 (2015).

Acknowledgements

The authors thank the Shiyanjia Lab (www.shiyanjia.com) for the VSM and XRF analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, A., Yang, X., Li, C. et al. Resource Utilization of Iron Ore Tailings to Recover SiO2 Sand Through S-HGMS: Parametric Optimization and Mechanism Analysis. JOM 76, 2392–2402 (2024). https://doi.org/10.1007/s11837-024-06447-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06447-z