Abstract

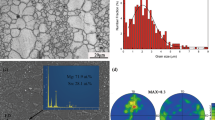

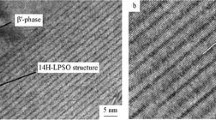

The commercial ZK60 magnesium alloy processed by solution heat treatment was dynamically loaded with a high strain rate by means of the split Hopkinson pressure bar (SHPB), and the dynamic instantaneous precipitation of second phases was investigated in the present work for the first time. TEM observations indicated that the β´1 with average length/diameter of 68.24–19.27 nm and β′2 phases with an average diameter of 16.15 nm precipitated within the dynamic deformation time of 180 μs at 3000 s−1. The adiabatic temperature rise generated by the dynamic deformation increases the atomic diffusion coefficient of solute atoms, which contributes to the generation of precipitated phases. Therefore, the precipitation of the second phases is thermodynamically feasible. It is also feasible to kinetically accelerate the rate of atomic diffusion to eventually lead to the instantaneous precipitation of the mass of the β′1 and β′2 phases, due to the combined effects of adiabatic temperature rise, high deviatoric stresses, high-density dislocation (vacancies) formed by the dynamic loading, and the initial supersaturated vacancies formed by the T4 treatment. Since the high-density dislocation was generated and the numerous reinforcing phases (β′1 and β′2) were precipitated in the matrix during deformation, the Vickers hardness values of alloy increased from 64.4 HV to 93.1 HV.

Similar content being viewed by others

Data and code availability

The data underlying this article cannot be shared publicly for the privacy of individuals that participated in the study.

References

P. Peng, J. She, Q. Yang, S. Long, A. Tang, J. Zhang, Q. Dai, and F. Pan, J. Alloy. Compd. 935, 168008 https://doi.org/10.1016/j.jallcom.2022.168008 (2023).

Q. Chen, R. Chen, J. Su, Q. He, B. Tan, C. Xu, X. Huang, Q. Dai, and J. Lu, J. Magn. Alloys 10, 2384–2397 https://doi.org/10.1016/j.jma.2022.09.001 (2022).

Z.Z. Jin, M. Zha, S.Q. Wang, S.C. Wang, C. Wang, H.L. Jia, and H.Y. Wang, J. Magn. Alloys 10, 1191–1206 https://doi.org/10.1016/j.jma.2022.04.002 (2022).

P.S. Ghosh, A. Sen, S. Chattopadhyaya, S. Sharma, J. Singh, C. Li, G. Królczyk, and S. Rajkumar, Heliyon 8, e11710 https://doi.org/10.1016/j.heliyon.2022.e11710 (2022).

P. Sekar, S. Narendranath, and V. Desai, J. Magn. Alloys 9, 1147–1163 https://doi.org/10.1016/j.jma.2020.11.001 (2021).

Y. Li, H. Jahr, J. Zhou, and A.A. Zadpoor, Acta Biomater. 115, 29–50 https://doi.org/10.1016/j.actbio.2020.08.018 (2020).

J. Liang, S. Wu, Z. Lei, Y. Chen, X. Zhang, B. Li, M. Jiang, and Y. Chen, Mater. Character. 194, 112361 https://doi.org/10.1016/j.matchar.2022.112361 (2022).

J. Buha, J. Mater. Sci. Eng. A 492, 11–19 https://doi.org/10.1016/j.msea.2008.02.038 (2008).

X. Gao, and J.F. Nie, Scripta Mater. 56, 645–648 https://doi.org/10.1016/j.scriptamat.2007.01.006 (2007).

A. Malik, F. Nazeer, S.Z.H. Naqvi, J. Long, C. Li, Z. Yang, and Y. Huang, J. Market. Res. 16, 801–813 https://doi.org/10.1016/j.jmrt.2021.12.051 (2022).

X. Xu, J. Zhang, H. Liu, Y. He, and W. Zhao, Mater. Sci. Eng. A. https://doi.org/10.1016/j.msea.2019.03.011 (2019).

M.A. Basith, N.C. Reddy, S. Uppalapati, and S.P. Jani, Mater. Today Proc. 45, 1684–1690 https://doi.org/10.1016/j.matpr.2020.08.561 (2021).

L. Shen, and Y. Liu, Int. J. Mater. Res. Technol. 160, 104077 https://doi.org/10.1016/j.ijimpeng.2021.104077 (2022).

A.A. Luo, A.K. Sachdev, and D. Apelian, J. Mater. Process. Technol. 306, 117606 https://doi.org/10.1016/j.jmatprotec.2022.117606 (2022).

J. Wang, L. Zhang, P. Jin, L. Chen, X. Yuan, and H. Ma, J. Alloy. Compd. 908, 164540 https://doi.org/10.1016/j.jallcom.2022.164540 (2022).

L. Zhang, Mater. Sci. Eng., A 844, 143166 https://doi.org/10.1016/j.msea.2022.143166 (2022).

W. Shi, S. Lu, J. Shen, B. Chen, J. Umeda, Q. Wei, K. Kondoh, and Y. Li, Mater. Sci. Eng., A 830, 142321 https://doi.org/10.1016/j.msea.2021.142321 (2022).

Z. Zeng, M. Salehi, A. Kopp, S. Xu, M. Esmaily, and N. Birbilis, J. Magn. Alloys 10, 1511–1541 https://doi.org/10.1016/j.jma.2022.03.001 (2022).

X. Liu, H. Yang, B. Zhu, Y. Wu, W. Liu, and C. Tang, J. Magn. Alloys. https://doi.org/10.1016/j.jma.2021.07.030 (2021).

M. Du, L. Chen, Q. Fang, L. Yan, and X. Hu, Mater. Today Commun. 33, 104852 https://doi.org/10.1016/j.mtcomm.2022.104852 (2022).

T. Ali, L. Wang, X. Cheng, H. Cheng, Y. Yang, A. Liu, X. Xu, Z. Zhou, Z. Ning, Z. Xu X. Min, J. Mater. Sci. Technol. Shenyang China 78 (2021) 238–246. https://doi.org/10.1016/j.jmst.2020.11.033.

S. Kim, M.C. Jo, D.W. Suh, H.K. Kim, S.S. Sohn, and S. Lee, Mater. Sci. Eng., A 814, 141127 https://doi.org/10.1016/j.msea.2021.141127 (2021).

S.J. Yang, and Y. Yang, Scripta Mater. 181, 115–120 https://doi.org/10.1016/j.scriptamat.2020.02.024 (2020).

C. Genevois, D. Fabrègue, A. Deschamps, and W.J. Poole, Mater. Sci. Eng., A 441, 39–48 https://doi.org/10.1016/j.msea.2006.07.151 (2006).

A. Deschamps, G. Fribourg, Y. Bréchet, J.L. Chemin, and C.R. Hutchinson, Acta Mater. 60, 1905–1916 https://doi.org/10.1016/j.actamat.2012.01.002 (2012).

G. Sha, Y.B. Wang, X.Z. Liao, Z.C. Duan, S.P. Ringer, and T.G. Langdon, Acta Mater. 57, 3123–3132 https://doi.org/10.1016/j.actamat.2009.03.017 (2009).

S. Liu, S. Wang, L. Ye, Y. Deng, and X. Zhang, Mater. Sci. Eng., A 677, 203–210 https://doi.org/10.1016/j.msea.2016.09.047 (2016).

D.T. Hong Hue, V.K. Tran, V.L. Nguyen, L. Van Lich, V.H. Dinh, T.G and Nguyen, Vacuum, 201 (2022) 111104. https://doi.org/10.1016/j.vacuum.2022.111104.

M.A. Afifi, Y.C. Wang, and T.G. Langdon, Mater. Sci. Eng., A 784, 139287 https://doi.org/10.1016/j.msea.2020.139287 (2020).

M.A. Khan, Y. Wang, M. Hamza, G. Yasin, M. Tabish, C. Feng, W.Q. Khan, T. Ahmad, W.B. Liao, and M.A. Afifi, Mater. Charact. 180, 111398 https://doi.org/10.1016/j.matchar.2021.111398 (2021).

D. H. Li, Y. Yang, T. Xu, H.G. Zheng, Q. S. Zhu, Q. M, Zhang. Mater. Sci. Eng. A 527: 3529–3535 (2010)

L. Jiang, Y. Yang, Z. Wang, and H. Hu, Mater. Sci. Eng., A 711, 317–324 https://doi.org/10.1016/j.msea.2017.10.111 (2018).

Y. Yang, S.J. Yang, and L.H. Jiang, Mater. Charact. 156, 109840 https://doi.org/10.1016/j.matchar.2019.109840 (2019).

S. Kim, M.C. Jo, T.W. Park, J. Ham, S.S. Sohn, and S. Lee, Mater. Sci. Eng., A 804, 140757 https://doi.org/10.1016/j.msea.2021.140757 (2021).

T. Ye, Y. Wu, A. Liu, C. Xu, and L. Li, Vacuum 159, 37–44 https://doi.org/10.1016/j.vacuum.2018.10.013 (2019).

Y. Yang, F. Jiang, B.M. Zhou, X.M. Li, H.G. Zheng, and Q.M. Zhang, Mater. Sci. Eng., A 528, 2787–2794 https://doi.org/10.1016/j.msea.2010.12.053 (2011).

F. Zhang, Z. Liu, M. Yang, G. Su, R. Zhao, P. Mao, F. Wang, and S. Sun, Mater. Sci. Eng., A 771, 138571 https://doi.org/10.1016/j.msea.2019.138571 (2020).

J. Liang, Z. Lei, Y. Chen, S. Wu, X. Chen, M. Jiang, and S. Cao, Mater. Sci. Eng., A 839, 142858 https://doi.org/10.1016/j.msea.2022.142858 (2022).

P. Li, K. Yuan, W. Guo, R. Wang, L. Chen, M. Gao, and P. Du, J. Market. Res. 18, 637–657 https://doi.org/10.1016/j.jmrt.2022.02.121 (2022).

X. Zhou, H. Yan, J. Chen, W. Xia, B. Su, L. Yu, W. Huang, and M. Song, J. Alloy. Compd. 819, 152961 https://doi.org/10.1016/j.jallcom.2019.152961 (2020).

Z. Li, Z. Peng, Y. Qiu, K. Qi, Z. Chen, and X. Guo, J. Mater. Res. Technol. 9, 11201–11219 https://doi.org/10.1016/j.jmrt.2020.08.004 (2020).

T. Zhang, H. Cui, X. Cui, H. Chen, E. Zhao, L. Chang, Y. Pan, R. Feng, S. Zhai, and S. Chai, J. Market. Res. 9, 133–141 https://doi.org/10.1016/j.jmrt.2019.10.038 (2020).

W. Ren, R. Xin, J. Xu, B. Song, L. Zhang, and Q. Liu, J. Alloy. Compd. 792, 610–616 https://doi.org/10.1016/j.jallcom.2019.04.085 (2019).

J.H. Cho, S.H. Han, H.T. Jeong, and S.H. Choi, J. Alloy. Compd. 743, 553–563 https://doi.org/10.1016/j.jallcom.2017.12.275 (2018).

L. Tian, L. Liu, N. Hou, J. Zhou, W. Guo, Q. Yuan, F. Zaïri, and N. Ding, Mater. Today Commun. 26, 101708 https://doi.org/10.1016/j.mtcomm.2020.101708 (2021).

C. Li, and Y.D. Yu, Mater. Sci. Eng., A 559, 22–28 https://doi.org/10.1016/j.msea.2012.06.065 (2013).

M.A. Meyers, Dynamic Behavior of Materials (Wiley, New York, 1994), pp405–435.

J.F. Xiao, Z.H. Nie, C.W. Tan, G. Zhou, R. Chen, M.R. Li, X.D. Yu, X.C. Zhao, S.X. Hui, W.J. Ye, and Y.T. Lee, Mater. Sci. Eng., A 751, 191–200 https://doi.org/10.1016/j.msea.2019.02.068 (2019).

J. Xu, L. Huang, B. Xie, H. Su, and J. Li, J. Mater. Process. Technol. 303, 117516 https://doi.org/10.1016/j.jmatprotec.2022.117516 (2022).

A. Malik, U.M. Chaudry, T. Yan, J. Long, C. Li, and Y. Wang, J. Alloy. Compd. 902, 163755 https://doi.org/10.1016/j.jallcom.2022.163755 (2022).

Y. Yang, Z. Wang, and L.H. Jiang, J. Alloy. Compd. 705, 566–571 https://doi.org/10.1016/j.jallcom.2017.02.158 (2017).

J.F. Nie, Metall. Mater. Trans. A 43, 3891–3939 https://doi.org/10.1007/s11661-012-1217-2 (2012).

J. Ren, Y. Xu, X. Zhao, and P. Zhao, Mater. Sci. Eng., A 719, 178–191 https://doi.org/10.1016/j.msea.2018.02.019 (2018).

L. Hua, P. Zhou, Y. Song, and Q. Sun, Mater Sci. Eng. B Adv. Function. Solid-State Mater. 282, 115751 https://doi.org/10.1016/j.mseb.2022.115751 (2022).

R.A. Graham, Solids Under High-Pressure Shock Compression, Mechanics, Physics, and Chemistry (Springer, New York, NY, 1993), pp130–145.

R.A. Graham, B. Morosin, E.L. Venturini, and M.J. Carr, Annu. Rev. Mater. Res. 16, 315–41 https://doi.org/10.1146/annurev.ms.16.080186.001531 (1986).

H. Kressel, and N. Brown, J. Appl. Physiol. 38, 1618–1625 https://doi.org/10.1063/1.1709733 (1967).

K.S. Reddy, Y. Govindaraj, and L. Neelakantan, Electrochim. Acta 439, 141727 https://doi.org/10.1016/j.electacta.2022.141727 (2023).

G. Zhao, J. Zhang, S. Zhang, G. Wang, J. Han, and C. Zhang, J. Alloy. Compd. 935, 167987 https://doi.org/10.1016/j.jallcom.2022.167987 (2023).

X. Xie, Z. Guo, J. Xiao, Z. Liang, S. Wei, W. Feng, Z. Zhao, and X. Liu, J. Market. Res. 22, 1961–1970 https://doi.org/10.1016/j.jmrt.2022.12.042 (2023).

A. Deschamps, F. Bley, F. Livet, D. Fabregue, and L. David, Phil. Mag. 83, 677–692 https://doi.org/10.1080/0141861021000051091 (2003).

Acknowledgements

This work is supported by the National Natural Science Foundation of China (Nos. 51871243, 51574290), the Guangdong-Hong Kong-Macao Joint Laboratory for Neutron Scattering Science and Technology (HT-CSNS-DG-CD-0092/2021), the Open Fund of the Hubei Longzhong Laboratory (No. 2022KF-08), the Shock and Vibration of Engineering Materials and Structures Key Laboratory of Sichuan Province (No. 22kfgk06), the Hunan Provincial Natural Science Foundation of China (No. 2019JJ40381), and the State Key Laboratory of Precision Blasting and Hubei Key Laboratory of Blasting Engineering (No. PBSKL2022C01).

Author information

Authors and Affiliations

Contributions

YY: project administration, funding, acquisition, conceptualization, supervision, validation, writing - review & editing. YZ: investigation, provision of experimental materials, data curation, visualization, writing - original draft, formal analysis. LH: data curation, writing - review & editing. DL: validation. SW: project administration. YK: Project administration.

Corresponding author

Ethics declarations

Ethical approval

The manuscript is prepared as per the ethical standard of the journal.

Conflict of Interest

We declared that we have no conflicts of interest to this work, and we have no financial and personal relationships with other people or organizations.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, Y., Zhan, Y., Hu, L. et al. Study on the Dynamic Instantaneous Precipitation of ZK60-T4 Magnesium Alloy Under High Strain-Rate Loading. JOM 76, 2016–2026 (2024). https://doi.org/10.1007/s11837-024-06394-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06394-9