Abstract

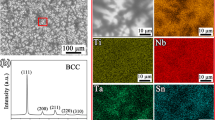

To find an effective method for preparing low-H/O impurity pollution powders of refractory complex concentrated alloys (RCCAs) with decent plasticity levels, the hydride–dehydride process and behavior characteristics of Ti2ZrTa0.75 RCCA were investigated. After the hydrogenation process at a temperature of 600°C and a hydrogen pressure of 0.2 MPa for a time of 2 h, Ti2ZrTa0.75 RCCA transformed into M3H2 metal hydrides with hydrogen concentrations of 0.61 wt.% and then hydrogen-induced fragmentation. Meanwhile, fragmentary RCCAs have a low impurity oxygen content (0.0545 wt.%). Then, nearly spherical powders with average particle sizes of 4.5 μm were obtained by ball milling for 4 h. Finally, the dehydrogenation process at 450°C for 2 h reduced the hydrogen concentration in the Ti2ZrTa0.75 RCCA powder to 0.0074 wt.%, while the near-spherical shape and small particle size (D50 = 9.4 μm) were maintained, with the near-spherical shaped RCCA powders with BCC + HCP dual-phase structures. By fitting the hydrogenation and dehydrogenation kinetics curves, the hydrogenation and dehydrogenation behaviors of Ti2ZrTa0.75 RCCA were mainly controlled by the diffusion of hydrogen atoms. The results of this work proved that spherical Ti2ZrTa0.75 RCCA powder with low-H/O impurity pollution and a small size could be successfully prepared by the hydride–dehydride method. The hydride–dehydride method was thus an effective method for preparing low-H/O impurity pollution powder composed of RCCAs with decent plasticity levels.

Similar content being viewed by others

References

D.B. Miracle, and O.N. Senkov, Acta Mater. 122, 448 (2017).

O.N. Senkov, S. Gorsse, and D.B. Miracle, Acta Mater. 175, 394 (2019).

H.L. Huang, Y. Wu, J.Y. He, H. Wang, X.J. Liu, K. An, W. Wu, and Z.P. Lu, Adv. Mater. 29, 1 (2017).

M. Li, Z.H. Zhang, A.S. Thind, G.D. Ren, R. Mishra, and K.M. Flores, Acta Mater. 213, 116919 (2021).

O.N. Senkov, D.B. Miracle, and S.I. Rao, Mater. Sci. Eng. A 820, 141512 (2021).

H.W. Yao, J.W. Qiao, J.A. Hawk, H.F. Zhou, M.W. Chen, and M.C. Gao, J. Alloy. Compd. 696, 1139 (2017).

S. Zhang, Z. Wang, H.J. Yang, J.W. Qiao, Z.H. Wang, and Y.C. Wu, Intermetallics 121, 106699 (2020).

W. Guo, W. Dmowski, J.Y. Noh, P. Rack, P.K. Liaw, and T. Egami, Metall. Mater. Trans. A 44, 1994–1997 (2013).

L.R. Owen, E.J. Pickering, H.Y. Playford, H.J. Stone, M.G. Tucker, and N.G. Jones, Acta Mater. 122, 11 (2017).

Y. Yuan, Z. Yang, X. Liang, Z.F. Lei, H.L. Huang, H. Wang, X.J. Liu, K. An, W. Wu, and Z.P. Lu, Mater. Res. Lett. 7, 225 (2019).

Z.M. Li, K.G. Pradeep, Y. Deng, and D. Raabe, Nature 534, 227 (2016).

H. Huang, Y. Wu, J. He, H. Wang, X. Liu, K. An, W. Wu, and Z. Lu, Adv. Mater. 29, 1701678 (2017).

J.P. Couzinié, O.N. Senkov, D.B. Miracle, and G. Dirras, Data Brief 21, 1622 (2018).

O.N. Senkov, D.B. Miracle, K.J. Chaput, and J.P. Couzinie, J. Mater. Res. 33, 3092 (2018).

K.R. Ren, H.Y. Liu, R. Chen, Y. Tang, B.Y. Guo, S. Li, J. Wang, R.X. Wang, and F.Y. Lu, Mater. Sci. Eng. A 827, 142074 (2021).

S. Li, J. Wang, J.Z. He, R.M. Xue, R.X. Wang, D. Niu, R. Chen, Y. Tang, and S.X. Bai, Intermetallics 159, 107912 (2023).

S. Shuang, Q. Yu, X. Gao, Q.F. He, J.Y. Zhang, S.Q. Shi, and Y. Yang, J. Mater. Sci. Technol. 109, 197 (2022).

Y.L. Chou, Y.C. Wang, J.W. Yeh, and H.C. Shih, Corros. Sci. 52, 3481 (2010).

M.A. Hemphill, T. Yuan, G.Y. Wang, J.W. Yeh, C.W. Tsai, A. Chuang, and P.K. Liaw, Acta Mater. 60, 5723 (2012).

J.Z. He, Y. Tang, Z.R. Zhang, S. Li, L.A. Zhu, Y.C. Ye, H. Luo, and S.X. Bai, Corros. Sci. 209, 110778 (2022).

R.X. Wang, Y. Tang, S. Li, Y.L. Ai, Y.Y. Li, B. Xiao, L.A. Zhu, and S.X. Bai, J. Alloy. Compd. 825, 154099 (2020).

Y.K. Cao, Y. Liu, B. Liu, W.D. Zhang, and J.W. Wang, T Nonferr Metal Soc 29, 1476 (2019).

Q. Xu, T. Zhu, Z.H. Zhong, X.Z. Cao, and H. Tsuchida, J. Alloy. Compd. 888, 161518 (2021).

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Intermetallics 18, 1758 (2010).

O.N. Senkov, D.B. Miracle, K.J. Chaput, and J.P. Couzinie, J Mater Res 33, 3092 (2018).

B. Kang, J.H. Lee, H.J. Ryu, and S.H. Hong, Mater. Sci. Eng. A 712, 616 (2018).

J.Z. He, Y.T. Qiao, R.X. Wang, Y. Tang, S. Li, X.Y. Liu, Y.C. Ye, L.A. Zhu, Z. Wang, and S.X. Bai, J. Alloy. Compd. 891, 156 (2022).

Y. Xing, C.J. Li, Y.K. Mu, Y.D. Jia, K.K. Song, J. Tan, G. Wang, Z.Q. Zhang, J.H. Yi, and J. Eckert, J. Mater. Sci. Technol. 132, 119 (2023).

X.F. Li, J. Yin, J. Zhang, Y.F. Wang, X.L. Song, Y. Zhang, and X.C. Ren, J. Mater. Sci. Technol. 122, 20 (2022).

T.W. Na, K.B. Park, S.Y. Lee, S.M. Yang, J.W. Kang, T.W. Lee, K. Park, and H.K. Park, J. Alloy. Compd. 817, 152757 (2020).

S.C. Marques, A.V. Castilho, and D.S. Santos, Scr. Mater. 201, 113957 (2021).

K.B. Park, J.Y. Park, Y.D. Kim, T.W. Na, C.B. Mo, J. Chou, H.S. Kang, and H.K. Park, Intermetallics 130, 125060 (2021).

W.H. Lee, K.B. Park, K.W. Yi, S.Y. Lee, K. Park, T.W. Lee, and H.K. Park, Metals-Basel 9, 1296 (2019).

M. Akmal, H.K. Park, and H.J. Ryu, Mater Chem Phys 273, 125060 (2021).

B. Zhang, Y. Tang, S. Li, Y.C. Ye, L.A. Zhu, Z.R. Zhang, Z. Wang, and S.X. Bai, Entropy 23, 125060 (2021).

Y.D. Wu, Y.H. Cai, X.H. Chen, T. Wang, J.J. Si, L. Wang, Y.D. Wang, and X.D. Hui, Mater. Design 83, 651 (2015).

O.N. Senkov, G.B. Wilks, J.M. Scott, and D.B. Miracle, Intermetallics 19, 698 (2011).

Z.D. Han, N. Chen, S.F. Zhao, L.W. Fan, G.N. Yang, Y. Shao, and K.F. Yao, Intermetallics 84, 153 (2017).

H. Liu, L.X. Lian, and Y. Liu, Mater. Man Process 34, 630 (2019).

Q.J. Li, L. Zhang, B.B. Li, and X.H. Xue, Rare Metal Mater. Eng. 22, 56 (2020).

W. Xu, S.Q. Xiao, X. Lu, G. Chen, C.C. Liu, and X.H. Qu, J. Mater. Sci. Technol. 35, 322 (2019).

I.S. Batra, R.N. Singh, P. Sengupta, B.C. Maji, K. Madangopal, K.V. Manikrishna, R. Tewari, and G.K. Dey, J. Nucl. Mater. 38, 389 (2009).

J. Montero, L. Laversenne, V. Nassif, G. Zepon, M. Sahlberg, and C. Zlotea, J. Alloy. Compd. 835, 155376 (2020).

O.N. Senkov, S.V. Senkova, D.M. Dimiduk, C. Woodward, and D.B. Miracle, J. Mater. Sci. 47, 6522 (2012).

H.S. Grewal, R.M. Sanjiv, H.S. Arora, R. Kumar, A. Ayyagari, S. Mukherjee, and H. Singh, Adv. Eng. Mater. 19, 1700182 (2017).

S.C. Marques, and A.V. Castilho, Scripta Mater. 201, 113957 (2021).

G. Hachet, A. Metsue, A. Oudriss, and X. Feaugas, Acta Mater. 148, 280 (2018).

D.S. Santos, S. Miraglia, and D. Fruchart, J. Alloy. Compd. 291, 113957 (1999).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant Nos. 52171166, 11972372 and U20A20231). The SEM analyses of this work was supported by Sinoma Institute of Materials Research (Guang Zhou) Co., Ltd.

Author information

Authors and Affiliations

Contributions

SL: Conceptualization, Methodology, Investigation, Writing-Review and Editing, Visualization, Funding acquisition. JH: Conceptualization, Methodology, Resources, Writing-Original Draft. ZL: Writing—review and editing, Methodology. RW: Validation, Resources, Project administration, Review, Data Curation. ZZ: Validation. LZ: Data Curation. YT: Formal analysis, Methodology, Writing—review and editing, Funding acquisition. SB: Funding acquisition, Supervision, Writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, S., He, J., Liu, Z. et al. Hydride–Dehydride Processes and Behaviors for Ductile Refractory Complex Concentrated Alloys. JOM 76, 2069–2078 (2024). https://doi.org/10.1007/s11837-024-06377-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-024-06377-w