Abstract

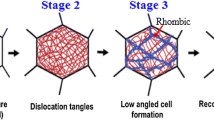

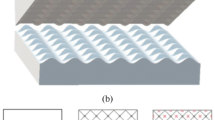

To explore the influence of deformation temperature on the tensile and microstructure of high-strength Al alloy, pre-aged AA7075 sheets were processed by cryorolling and room temperature rolling. Hardness and tensile tests examined the mechanical properties of AA7075. The microstructures of AA7075 under different rolling conditions were analyzed by scanning electron microscopy, optical microscopy, x-ray diffraction, electron backscatter diffraction and transmission electron microscope. The results show that the ultimate tensile strength and hardness of cryorolled AA7075 are 672.6 MPa and 226.6 HV, respectively. When the rolling reduction rate reaches 60%, the cryorolled AA7075 remains great ductility of 5.7%. The cryorolling can effectively result in higher dislocation densities, thus improving the strength of the AA7075 sheets. Meanwhile, the cryorolled AA7075 after pre-aging can avoid the occurrence of shear bands and microcracks to improve the material's ductility.

Similar content being viewed by others

Data availability

The data sets generated and analyzed during the current study are available from the corresponding authors on reasonable request.

References

Y. Aboura, A.J. Garner, R. Euesden, Z. Barrett, C. Engel, N.J.H. Holroyd, P.B. Prangnell, and T.L. Burnett, Corros. Sci. 199, 110161 (2022).

Y.F. Wang, J.R. Xing, Y.X. Zhou, C. Kong, and H.L. Yu, J. Alloys Compd. 942, 169044 (2023).

L. Bao, K. Li, J.Y. Zheng, Y.L. Zhang, K. Zhan, Z. Yang, B. Zhao, and V. Ji, Surf. Coat. Tech. 440, 128481 (2022).

Q. Sun, M. Yang, Y. Jiang, L. Lei, and Y. Zhang, J. Alloys Compd. 911, 165009 (2022).

Q.D. Zhang, F.Z. Sun, M. Liu, and W.C. Liu, J. Cent. South Univ. 29, 3544–3556 (2022).

J. Liu, Z.Y. Du, J.L. Su, J. Tang, F.L. Jiang, D.F. Fu, J. Teng, and H. Zhang, J. Mater. Sci. Technol. 132, 154–165 (2023).

Y.S. Lee, D.H. Koh, H.W. Kim, and Y. Ahn, S. Scr. Mater. 147, 45–49 (2017).

E.V. Arcieri, S. Baragetti, and Ž Božić, Eng. Failure Analy. 138, 106380 (2022).

Y.Z. Wu, K.G. Luo, Y. Zhang, C. Kong, and H.L. Yu, J. Alloys Compd. 921, 166166 (2022).

F.L. Yu, Y. Zhang, C. Kong, and H.L. Yu, Mater. Sci. Eng. A 834, 142600 (2022).

F. Spieckermann, D. Şopu, V. Soprunyuk, M.B. Kerber, J. Bednarčík, A. Schökel, A. Rezvan, S. Ketov, B. Sarac, E. Schafler, and J. Eckert, Nat. Commun. 13, 127–127 (2022).

S.S. Yang, Z.D. Li, Y.X. Zhou, Z. Tan, C. Kong, and H. Yu, J. Alloys Compd. 931, 167556 (2023).

L. Mei, X.P. Chen, P. Ren, Y.Y. Nie, G.J. Huang, and Q. Liu, Mater. Sci. Eng. A 771, 138608 (2020).

K.P. Sushanta, and R. Jayaganthan, Mater. Des. 32, 3150–3160 (2011).

D. Wang, S.Q. Huang, Y.P. Yi, H.L. He, and C. Li, Mater. Charact. 187, 111831 (2022).

G.A. He, K. Li, Y. Yang, Y. Liu, W.K. Wu, and C. Huang, Mater. Sci. Eng. A 822, 141682 (2021).

F. Ye, Y.X. Yu, B.S. Zhang, J. Rong, D.L. He, B.S. Han, X.G. Ma, Y.S. Zeng, Y.J. Xu, and S.J. Wu, J. Mater. Res. Technol. 22, 2983–2995 (2023).

L. Wang, C. Kong, and H.L. Yu, J. Alloy. Compd. 900, 163442 (2022).

H.Q. Xiong, Y.X. Zhou, P. Yang, C. Kong, and H.L. Yu, Mater. Sci. Eng. A 853, 143764 (2022).

Y.L. Jia, Y. Pang, J. Yi, Q. Lei, Z. Li, and Z. Xiao, J. Alloys Compd. 942, 169033 (2023).

P.Y. Ying, C.H. Lin, Z.Y. Liu, S. Bai, V. Levchenko, P. Zhang, J.B. Wu, T. Yang, M. Huang, G. Yang, M. Liu, and M.J. Li, Metals 12, 1208 (2022).

J. Luo, H.Y. Luo, S.J. Li, R.Z. Wang, and Y. Ma, Mater. Des. 187, 108402 (2020).

H. Lin, P.G. Yuan, N. Zhao, Z.L. Hu, and H.J. Ma, Trans. Nonferr. Met. Soc. China 32, 790–800 (2022).

M. Cui, Y.H. Jo, Y.W. Kim, H.Y. Kim, and J.H. Lee, J. Mater. Res. Technol. 20, 238–245 (2022).

K. Huang, S. Huang, Y. Yi, F. Dong, and H. He, J. Alloy. Compd. 902, 163821 (2022).

R.K. Singh, S.S.S. Guraja, O.O. Ajide, G.M. Owolabi, and N. Kumar, Mater. Sci. Eng. A 865, 144636 (2023).

W. Li, K. Xiong, L.J. Yang, S.M. Zhang, J.J. He, Y.W. Wang, and Y. Mao, Mater. Sci. Eng. A 856, 144046 (2022).

L.L. Song, H.T. Gao, L. Bhatt, C. Kong, and H.L. Yu, Mater. Sci. Eng. A 874, 145069 (2023).

Z.B. Xu, H.J. Roven, and Z.H. Jia, Mater. Sci. Eng. A 648, 350–358 (2015).

G. Ribárik, and T. Ungár, Mater. Sci. Eng. A 528, 112–121 (2010).

N. Sadasivan, M. Balasubramanian, and B.R. Rameshbapu, J Manuf Process 59, 698–726 (2020).

H. Gu, L. Bhatta, H.T. Gao, Z.D. Li, C. Kong, and H.L. Yu, Mater. Sci. Eng. A 843, 143141 (2022).

S.J. Yuan, W.J. Cheng, W. Liu, and Y.C. Xu, J. Mater. Process. Technol. 284, 116743 (2020).

H. Zhao, L.Y. Ye, Q.S. Cheng, Y. Kang, and W.J. Zhang, Mater. Charact. 197, 112715 (2023).

Y. Liu, X.S. Zhao, J. Li, L. Bhatta, K.G. Luo, C. Kong, and H.L. Yu, J. Alloy. Compd. 860, 158449 (2021).

B. Song, X.L. Yi, Z.Y. Liu, J. Wang, J.G. Zhao, and P.Y. Ying, J. Alloy. Compd. 764, 62–72 (2018).

L. Mei, M.J. Yang, X.P. Chen, Q.Q. Jin, Y.Q. Wang, and Y.M. Li, Mater. Sci. Eng. A 867, 144716 (2023).

L.J. Li, H.J. Kang, S.R. Zhang, R.G. Li, X. Yang, Z.N. Chen, E.Y. Guo, and T.M. Wang, J. Alloys Compd. 938, 168656 (2023).

Y. Xiong, K.H. Shu, Y. Li, Z.G. Chen, X.Q. Zha, T.T. He, S. Han, and C.X. Wang, Mater. Sci. Eng. A 856, 144005 (2022).

K.K. Ma, H.M. Wen, T. Hu, T.D. Topping, D. Isheim, D.N. Seidman, E.J. Lavernia, and J.M. Schoenung, Acta Mater. 62, 141–155 (2014).

J.W. Won, S. Lee, S.H. Park, M. Kang, K.R. Lim, C.H. Park, and Y.S. Na, J. Alloys Compd. 742, 290–295 (2018).

R. Gao, Y. Li, Z. Li, X. Li, K. Wen, Y. Zhang, and B. Xiong, J. Mater. Res. Technol. 18, 5394–5405 (2022).

P.C. Zhao, G.J. Yuan, R.Z. Wang, B. Guan, Y.F. Jia, X.C. Zhang, and S.T. Tu, J. Mater. Sci. Technol. 83, 196–207 (2021).

X.L. Wen, B. Chen, Z. Chen, X. Lin, H.O. Yang, N. Kang, Q.Z. Wang, W.L. Wang, and W.D. Huang, Mater. Sci. Eng. A 847, 143290 (2022).

I. Sabirov, M.Y. Murashkin, and R.Z. Valiev, Mater. Sci. Eng. A 560, 1–24 (2013).

Y. Li, G.F. Xu, X.Y. Peng, G.Y. Guo, S.C. Liu, and X.P. Liang, J. Alloy. Compd. 906, 163977 (2022).

S.L. Liu, K.G. Luo, H. Gu, H.T. Gao, C. Kong, and H.L. Yu, Scr. Mater. 222, 115004 (2023).

S.I. Baik, R.K. Gupta, K.S. Kumar, and D.N. Seidman, Acta Mater. 205, 116568 (2021).

S. Zhang, X. Luo, G.Y. Zheng, N.Z. Zhai, Y.Q. Yang, and P.T. Li, Mater. Sci. Eng. A 832, 142482 (2022).

Acknowledgements

The authors appreciate the financial support from the National Natural Science Foundation of China (Grant No. 52105419), High-tech Industry Technology Innovation Leading Plan of Hunan Province (Grant No. 2022GK4032), Natural Science Foundation of Hunan Province, China (Grant No. 2022JJ40596), the Innovation Driven Program of Central South University (Grant No. 2019CX006), and the Research Fund of the Key Laboratory of the High-Performance Complex Manufacturing at Central South University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors confirm that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Gao, H., Xing, J. et al. Effect of Cryorolling After Pre-aging on Tensile Properties and Microstructures of AA7075 Plates. JOM 75, 4832–4844 (2023). https://doi.org/10.1007/s11837-023-06102-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06102-z