Abstract

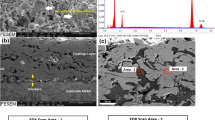

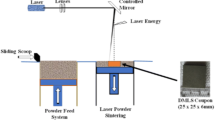

The powder-feed laser additive manufacturing method was applied to rebuild GTD 450 martensitic stainless steel specimens with Stellite 6. The H-factor parameter was defined as the controlling factor based on the values of the laser power, the cladding speed, and the powder feed rate. By depositing upper layers, cellular dendrites turned into columnar ones, which grew in the direction of heat transfer. A mixture of Co-rich γ and complex carbides of Cr, W, and Mo were found in the microstructure. The dilution was decreased with increasing the number of deposited layers; consequently, the increase in the hardness from the base metal to the cladded area was observed due to the less dilution by the base material as well as the less tempering effect of subsequent layers. The increased cladding speed decreased the H-factor. It was observed that, by controlling the H-factor, the wear properties of the cladded parts were increased by 8%.

Similar content being viewed by others

References

A.N. Isfahany, H. Saghafian, and G. Borhani, J. Alloys Compd. 509, 3931 (2011).

Z. Huang, G. Wang, S. Wei, C. Li, and Y. Rong, Front. Mech. Eng. 11, 242 (2016).

F. Khodabakhshi, M.H. Farshidianfar, A.P. Gerlich, M. Nosko, V. Trembo, and A. Khajepour, Mater. Sci. Eng. A 756, 545 (2019).

T. Kurzynowski, K. Gruber, W. Stopyra, B. Kuźnicka, and E. Chlebus, Mater. Sci. Eng. A. 718, 64 (2018).

M.K. Alam, A. Edrisy, J. Urbanic, and J. Pineault, J. Mater. Eng. Perform. 26, 1076 (2017).

A. Amirkhani, K. Shirvani, B. Beidokhti, and M.R. Rahimipour, Proc. Inst. Mech. Eng. Pt. L. J. Mater. Design Appl. 237(5), 1071 https://doi.org/10.1177/14644207221135044 (2022).

N. Jeyaprakash, C.H. Yang, S.S. Karuppasamy, and S.R. Dhineshkumar, Mater. Today Commun. 31, 103370 (2022).

S. Kersten, M. Praniewicz, T. Kurfess, and C. Saldana, Procedia Manuf. 48, 730 (2020).

K.D. Hao, M.C. Gong, Y.M. Pi, C. Zhang, M. Gao, and X.Y. Zeng, J. Mater. Process. Technol. 251, 127 (2018).

F. Khodabakhshi, M.H. Farshidianfar, A.P. Gerlich, M. Nosko, and V. Trembošová, Addit. Manuf. 31, 100915 (2020).

C. Chen, W. Meiping, H. Rui, G. Yuling, and M. Xiaojin, Opt. Laser Technol. 149, 107885 (2022).

C.M. Lin, Vacuum 115, 117 (2015).

M. Moradi, A. Ashoori, and A. Hasani, Opti. Laser Technol. 131, 106328 (2020).

P. Krakhmalev, I. Yadroitsava, G. Fredriksson, and I. Yadroitsev, Mater. Des. 87, 380 (2015).

R. Qin, X. Zhang, S. Guo, B. Sun, S. Tang, and W. Li, Surf. Coat. Technol. 285, 242 (2016).

K. Hao, M. Gao, C. Zhang, R. Wu, and X. Zeng, J. Mater. Process. Tech. 267, 359 (2019).

K.S. Mao, C. Sun, C.H. Shiau, K.H. Yano, P.D. Freyer, A.A. El-Azab, F.A. Garner, A. French, L. Shao, and J.P. Wharry, Scripta Mater. 178, 1 (2020).

R. Shi, S.A. Khairallah, T.T. Roehling, T.W. Heo, J.T. McKeown, and M.J. Matthews, Acta Mater. 184, 284 (2020).

S. Kou, Welding Metallurgy, 2nd edn. (Wiley, NJ, 2003).

Z. Li, G. Yu, X. He, S. Li, H. Li, and Q. Li, Results Phys. 12, 1062 (2019).

G. Cui, H. Liu, S. Li, G. Gao, M. Hassani, and Z. Kou, Sci. Technol. Adv. Mater. 21, 229 (2020).

A. Farnia, F. Malek Ghaini, V. Ocelik, and J.T.M. De Hosson, J. Mater. Sci. 48, 2714 (2013).

M. Moradi, A. Hasani, Z.M. Beiranvand, and A. Ashoori, Opt. Laser Technol. 131, 106455 (2020).

S.F. Nabavi, M.H. Farshidianfar, A. Farshidianfar, and B. Beidokhti, Optik 241, 166917 (2021).

M. Laridjani, A. Amadeh, and H. Kashani, Mater. Sci. Technol. 26, 1184 (2010).

G. Mirshekari, S. Daee, S.F. Bonabi, M. Tavakoli, A. Shafyei, and M. Safaei, Surf. Interfaces 9, 79 (2017).

S. Mahade, S.A. Awe, S. Bjorklund, F. Lukac, R. Musalek, and S. Joshi, Wear 500–501, 204375 (2022).

Acknowledgement

The authors would like to thank Taha Ghaleb Toos Co. (TGT) who has provided the laser cladding process for this work.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Marandi, S., Beidokhti, B., Sharifi, M. et al. Investigation of Microstructure and Wear Properties of Stellite 6 Laser Additive Manufactured Layers on Martensitic Stainless Steel Substrate. JOM 75, 4108–4114 (2023). https://doi.org/10.1007/s11837-023-06043-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06043-7