Abstract

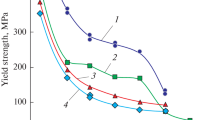

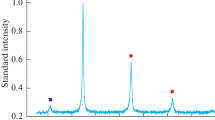

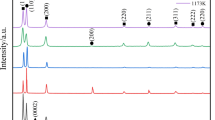

There is a lot of interest in examining high-entropy alloys (HEAs) due to the high work hardening and, consequently, increased strength and ductility synergy. In this research, the addition of 5 at.% Al element to the MnCrCoFeNi alloy and its effect on work hardening, deformation activation energy, critical temperature, and work-hardening exponent were investigated. For this purpose, the alloy was melted in a vacuum arc remelting furnace. After casting, homogenization, and cold rolling, the samples were annealed at 1100°C for 1 h. The produced alloy is a single-phase solid solution with a face-centered cubic (FCC) crystal lattice. Examining the work-hardening diagrams indicates that twinning exists in the microstructure of the alloy and is involved in the deformation mechanism. By adding 5 at.% aluminum to the Cantor alloy, the work-hardening exponent increased by 20% at room temperature and 200% at 600°C, recrystallization temperature increased up to ~ 200°C, and the activation energy of the deformation, ~ 445 kJ/mol, was calculated. The steady-state stress equation was also calculated versus to the strain rate, temperature, and the Zener parameter.

Similar content being viewed by others

References

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Mater. Sci. Eng. A 375–377, 213 (2004).

N.D. Stepanov, D.G. Shaysultanov, N.Y. Yurchenko, S.V. Zherebtsov, A.N. Ladygin, G.A. Salishchev, and M.A. Tikhonovsky, Mater. Sci. Eng. A 636, 188 (2015).

O.N. Senkov, J.M. Scott, S.V. Senkova, D.B. Miracle, and C.F. Woodward, J. Alloys Compd. 509, 6043 (2011).

C.-J. Tong, M.-R. Chen, J.-W. Yeh, S.-J. Lin, S.-K. Chen, T.-T. Shun, and S.-Y. Chang, Metall. Mater. Trans. A 36, 1263 (2005).

G.A. Salishchev, M.A. Tikhonovsky, D.G. Shaysultanov, N.D. Stepanov, A.V. Kuznetsov, I.V. Kolodiy, A.S. Tortika, and O.N. Senkov, J. Alloys Compd. 591, 11 (2014).

C. Dai, T. Zhao, C. Du, Z. Liu, and D. Zhang, J. Mater. Sci. Technol. 46, 64 (2020).

E. Abbasi, and K. Dehghani, J. Alloys Compd. 783, 292 (2019).

N.D. Stepanov, D.G. Shaysultanov, G.A. Salishchev, M.A. Tikhonovsky, E.E. Oleynik, A.S. Tortika, and O.N. Senkov, J. Alloys Compd. 628, 170 (2015).

M. Troparevsky, J. Morris, P. Kent, A. Lupini, and G. Stocks, Phys. Rev. X 5, 11041 (2015).

J.C. Rao, H.Y. Diao, V. Ocelík, D. Vainchtein, C. Zhang, C. Kuo, Z. Tang, W. Guo, J.D. Poplawsky, Y. Zhou, P.K. Liaw, and J.T.M. De Hosson, Acta Mater. 131, 206 (2017).

Z. Tang, M.C. Gao, H. Diao, T. Yang, J. Liu, T. Zuo, Y. Zhang, Z. Lu, Y. Cheng, Y. Zhang, K.A. Dahmen, P.K. Liaw, and T. Egami, JOM 65, 1848 (2013).

C. Varvenne, and W.A. Curtin, Scr. Mater. 138, 92 (2017).

J. Moon, J.W. Bae, M.J. Jang, S.M. Baek, D. Yim, B.-J. Lee, and H.S. Kim, Mater. Chem. Phys. 210, 187 (2018).

L. Lin, X. Xian, Z. Zhong, Y. Wu, and P.K. Liaw, Met. Mater. Int. 26, 1192 (2020).

J.Y. He, W.H. Liu, H. Wang, Y. Wu, X.J. Liu, T.G. Nieh, and Z.P. Lu, Acta Mater. 62, 105 (2014).

C. Yuhua, M. Yuqing, L. Weiwei, and H. Peng, Opt. Laser Technol. 91, 197 (2017).

Y. Bai, D.C. Nardi, X. Zhou, R.A. Picón, and J. Flórez-López, Comput. Struct. 256, 106639 (2021).

Z.Y. Zhu, Y.L. Liu, G.Q. Gou, W. Gao, and J. Chen, Sci. Rep. 11, 10020 (2021).

Y. Nan, Y. Ning, H. Liang, H. Guo, Z. Yao, and M.W. Fu, Mater. Des. 82, 84 (2015).

C.A.C. Imbert, and H.J. McQueen, Mater. Sci. Eng. A 313, 88 (2001).

X. Wang, Y. Zhang, and X. Ma, Mater. Sci. Eng. A 778, 139077 (2020).

R. Ebrahimi, S.H. Zahiri, and A. Najafizadeh, J. Mater. Process. Technol. 171, 301 (2006).

H. Mirzadeh, and A. Najafizadeh, Mater. Sci. Eng. A 527, 1856 (2010).

H. Deng, Y. Chen, Y. Jia, Y. Pang, T. Zhang, S. Wang, and L. Yin, J. Manuf. Process. 64, 379 (2021).

N. Nayan, G. Singh, S.V.S.N. Murty, A.K. Jha, B. Pant, K.M. George, and U. Ramamurty, Intermetallics 55, 145 (2014).

J.Y. He, C. Zhu, D.Q. Zhou, W.H. Liu, T.G. Nieh, and Z.P. Lu, Intermetallics 55, 9 (2014).

Y. Chen, S. Sun, T. Zhang, X. Zhou, and S. Li, Mater. Sci. Eng. A 771, 138545 (2020).

B. Zhang, Z. Wang, H. Yu, and Y. Ning, J. Alloys Compd. 900, 163515 (2022).

Y. Zhao, J. Mater. Res. Technol. 21, 546 (2022).

S. Zhang, B. Han, T. Zhang, Y. Chen, J. Xie, Y. Shen, L. Huang, X. Qin, Y. Wu, and K. Pu, Intermetallics 159, 107939 (2023).

X. Wang, X. Li, H. Xie, T. Fan, L. Zhang, K. Li, Y. Cao, X. Yang, B. Liu, and P. Bai, J. Mater. Res. Technol. 23, 1130 (2023).

L. Lai, M. Gan, J. Wang, L. Chen, X. Liang, J. Feng, and X. Chong, J. Am. Ceram. Soc. 106, 4343 (2023).

Y. Zhang, and P.W. Jie, Proc. Eng. 27, 1169–1178 (2012).

X. Yang, and Y. Zhang, Mater. Chem. Phys. 132, 233 (2012).

S. Guo, C. Ng, J. Lu, and C.T. Liu, J. Appl. Phys. 109, 103505 (2011).

L. Jiang, D. Qiao, Z. Cao, C. Lu, M. Song, and L. Wang, Mater. Sci. Eng. A 776, 139027 (2020).

Z. Zhang, Q. Yang, Z. Yu, H. Wang, and T. Zhang, Mater. Charact. 189, 111962 (2022).

H. Kaypour, S. Nategh, R. Gholamipour, and A. Khodabandeh, Mater. Res. Express 8, 66505 (2021).

W.H. Liu, Z.P. Lu, J.Y. He, J.H. Luan, Z.J. Wang, B. Liu, Y. Liu, M.W. Chen, and C.T. Liu, Acta Mater. 116, 332 (2016).

F. Otto, N.L. Hanold, and E.P. George, Intermetallics 54, 39 (2014).

G. Laplanche, O. Horst, F. Otto, G. Eggeler, and E.P. George, J. Alloys Compd. 647, 548 (2015).

Q.H. Tang, Y. Huang, Y.Y. Huang, X.Z. Liao, T.G. Langdon, and P.Q. Dai, Mater. Lett. 151, 126 (2015).

H. Shahmir, J. He, Z. Lu, M. Kawasaki, and T.G. Langdon, Mater. Sci. Eng. A 676, 294 (2016).

A. Rohatgi, K.S. Vecchio, and G.T. Gray, Metall. Mater. Trans. A 32, 135 (2001).

S. Asgari, E. El-Danaf, S.R. Kalidindi, and R.D. Doherty, Metall. Mater. Trans. A 28, 1781 (1997).

A.J. Zaddach, C. Niu, C.C. Koch, and D.L. Irving, JOM 65, 1780 (2013).

Y.-Y. Wang, C. Jia, M. Tayebi, and B. Hamawandi, Mater. Basel. 15, 6428 (2022).

X. Wang, J. Yang, P. Chi, E. Bahonar, and M. Tayebi, J. Alloys Compd. 901, 163422 (2021).

S.F. Mousavi, H. Sharifi, M. Tayebi, B. Hamawandi, and Y. Behnamian, Sci. Rep. 12, 15191 (2022).

Y.Y. Wang, C. Jia, M. Xu, M. Kaseem, and M. Tayebi, Mater. Basel. 16, 3885 (2023).

R.S. Mishra, N. Kumar, and M. Komarasamy, Mater. Sci. Technol. 31, 1259 (2015).

H.J. McQueen, and N.D. Ryan, Mater. Sci. Eng. A 322, 43 (2002).

M. Shaban, and B. Eghbali, Mater. Sci. Eng. A 527, 4320 (2010).

M. Annasamy, N. Haghdadi, A. Taylor, P. Hodgson, and D. Fabijanic, Mater. Sci. Eng. A 754, 282 (2019).

W.H. Liu, Y. Wu, J.Y. He, T.G. Nieh, and Z.P. Lu, Scr. Mater. 68, 526 (2013).

D.H. Lee, I.C. Choi, G. Yang, Z. Lu, M. Kawasaki, U. Ramamurty, R. Schwaiger, and J. Jang, Scr. Mater. 156, 129 (2018).

A. Smolej, B. Skaza, and M. Fazarinc, RMZ Mater. Geoenviron. 56, 389–399 (2009).

A.S. Hamada, L.P. Karjalainen, and M.C. Somani, Mater. Sci. Eng. A 467, 114 (2007).

C. Imbert, N.D. Ryan, and H.J. McQueen, Metall. Trans. A 15, 1855 (1984).

Y. Lü, D.A. Molodov, and G. Gottstein, Acta Mater. 59, 3229 (2011).

C.A.C. Imbert, and H.J. McQueen, Mater. Sci. Technol. 16, 524 (2000).

S.F. Medina, and P. Fabregue, J. Mater. Sci. 26, 5427 (1991).

Z. Wu, H. Bei, G.M. Pharr, and E.P. George, Acta Mater. 81, 428 (2014).

J.X. Fang, J.X. Wang, Y.J. Wang, H.T. He, D.B. Zhang, and Y. Cao, Mater. Sci. Eng. A 847, 143319 (2022).

N. Kumar, Q. Ying, X. Nie, R.S. Mishra, Z. Tang, P.K. Liaw, R.E. Brennan, K.J. Doherty, and K.C. Cho, Mater. Des. 86, 598 (2015).

R. Sivakami, S. Dhanuskodi, and R. Karvembu, Spectrochim Acta Part A Mol. Biomol. Spectrosc. 152, 43 (2016).

H. Kaypour, S. Nategh, R. Gholamipour, and A. Khodabandeh, Trans. Indian Inst. Met. 76, 119 (2023).

M.N. Hasan, Y.F. Liu, X.H. An, J. Gu, M. Song, Y. Cao, Y.S. Li, Y.T. Zhu, and X.Z. Liao, Int. J. Plast. 123, 178 (2019).

L. Sun, X. He, and J. Lu, Npj Comput. Mater. 4, 6 (2018).

P. Zhang, S. Wang, Z. Lin, X. Yue, Y. Gao, S. Zhang, and H. Yang, Vacuum 211, 111939 (2023).

C.X. Han, J.Q. Zhi, Z. Zeng, Y.S. Wang, B. Zhou, J. Gao, Y.X. Wu, Z.Y. He, X.M. Wang, and S.W. Yu, Appl. Surf. Sci. 623, 157108 (2023).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kaypour, H., Gholamipour, R., Khodabandeh, A. et al. Work Hardening and Kinetics Analysis of Al0.3MnCrCoFeNi High-Entropy Alloy. JOM 75, 4171–4181 (2023). https://doi.org/10.1007/s11837-023-06040-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06040-w