Abstract

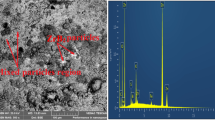

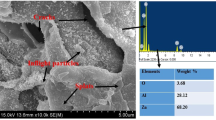

Advanced high-strength low alloy (HSLA) steels with outstanding corrosion resistance are extensively applied in marine engineering. However, corrosion sensitivity increases with steel strength. In this study, we developed a yield strength of 890 MPa ultra-high-strength offshore steel with superior corrosion resistance by regulating co-precipitation nanoparticles through co-alloying Al and Cu. Dispersed nanoparticles reduce lattice mismatch with the matrix and decrease pitting sensitivity, promoting the formation of a more homogeneous and dense passive film in the early corrosion stage. Al in EH890 steel is more prone to react with oxygen, resulting in the formation of Al2O3, which increases the protection of the passivation film. As a result, the corrosion potential of EH890 steel is higher, and its corrosion current density is five times lower than that of EH690 steel in 3.5 wt.% NaCl solution. As the corrosion progresses, Cu and Al can also encourage the formation of α-FeOOH in the rust layer, providing better protection to the substrate material. The EH890 steel has improved pitting resistance and electrochemical durability. This strategy may be informative for the development of advanced HSLA steels with superior corrosion resistance.

Similar content being viewed by others

References

F. Cai, Y. Huang, S. Xing, Y. Xu, X. Zhao, X. Wang, Z. Wang, and J.W. Ringsberg, Corros. Sci. 217, 111146 https://doi.org/10.1016/j.corsci.2023.111146 (2023).

L. Li, S. Lou, and C. Wang, JOM 74, 3607 https://doi.org/10.1007/s11837-022-05281-5 (2022).

J. Zhao and Z. Jiang, Prog. Mater Sci. 94, 174 https://doi.org/10.1016/j.pmatsci.2018.01.006 (2018).

H. Ma, L. Chen, J. Zhao, Y. Huang, and X. Li, Mater. Sci. Eng. A 773, 138884 https://doi.org/10.1016/j.msea.2019.138884 (2020).

V.G. Gavriljuk, B.D. Shanina, and H. Berns, Acta Mater. 56, 5071 https://doi.org/10.1016/j.actamat.2008.06.021 (2008).

L. Kan, Q. Ye, Z. Wang, and T. Zhao, Mater. Sci. Eng. A 855, 143875 https://doi.org/10.1016/j.msea.2022.143875 (2022).

Y. Wang, J. Wu, D. Zhang, E. Li, and L. Zhu, Bioelectrochemistry 141, 107884 https://doi.org/10.1016/j.bioelechem.2021.107884 (2021).

C.S. Wang, C.Y. Tsai, C.G. Chao, and T.F. Liu, Mater. Trans. 48, 2973 https://doi.org/10.2320/matertrans.MER2007138 (2007).

L.N. Xu, B. Wang, J.Y. Zhu, W. Li, and Z.Y. Zheng, Appl. Surf. Sci. 379, 39 https://doi.org/10.1016/j.apsusc.2016.04.049 (2016).

C. Liu, R.I. Revilla, D.W. Zhang, Z.Y. Liu, A. Lutz, F. Zhang, T.L. Zhao, H.C. Ma, X.G. Li, and H. Terryn, Corros. Sci. 138, 96 https://doi.org/10.1016/j.corsci.2018.04.007 (2018).

M. Kadowaki, I. Muto, Y. Sugawara, and N. Hara, Corros. Sci. 200, 110251 https://doi.org/10.1016/j.corsci.2022.110251 (2022).

A.A. Becerra Araneda, M.A. Kappes, M.A. Rodríguez, and R.M. Carranza, Corros. Sci. 198, 110121 https://doi.org/10.1016/j.corsci.2022.110121 (2022).

M. Nishimoto, I. Muto, Y. Sugawara, and N. Hara, ISIJ Int. 60, 196 https://doi.org/10.2355/isijinternational.ISIJINT-2019-408 (2019).

M. Narimani, E. Hajjari, M. Eskandari, and J.A. Szpunar, J. Constr. Steel Res. 203, 107782 https://doi.org/10.1016/j.jcsr.2023.107782 (2023).

J. Sun and K. Dilger, J. Mater. Res. Technol. 24, 557 https://doi.org/10.1016/j.jmrt.2023.03.016 (2023).

Y. Tian, M.-C. Zhao, Y.-P. Zeng, X.-B. Shi, W. Yan, K. Yang, and T.-Y. Zeng, JOM 74, 2409 https://doi.org/10.1007/s11837-022-05202-6 (2022).

D. Raabe, D. Ponge, O. Dmitrieva, and B. Sander, Scr. Mater. 60, 1141 https://doi.org/10.1016/j.scriptamat.2009.02.062 (2009).

R.J. Shi, Z.D. Wang, L.J. Qiao, and X.L. Pang, J. Mater Sci. Technol. 35, 1940 https://doi.org/10.1016/j.jmst.2019.05.009 (2019).

M.E. Fine, S. Vaynman, D. Isheim, Y.W. Chung, S.P. Bhat, and C.H. Hahin, Metall. Mater. Trans. A 41, 3318 https://doi.org/10.1007/s11661-010-0485-y (2010).

S.G. Lee, S.S. Sohn, B. Kim, W.G. Kim, K.K. Um, and S. Lee, Mater. Sci. Eng. A 715, 332 https://doi.org/10.1016/j.msea.2018.01.021 (2018).

Y.U. Heo, Y.K. Kim, J.S. Kim, and J.K. Kim, Acta Mater. 61, 519 https://doi.org/10.1016/j.actamat.2012.09.068 (2013).

P.K. Ray, R.I. Ganguly, and A.K. Panda, Mater. Sci. Eng. A 346, 122 https://doi.org/10.1016/S0921-5093(02)00526-9 (2003).

Z.B. Jiao, J.H. Luan, M.K. Miller, and C.T. Liu, Acta Mater. 97, 58 https://doi.org/10.1016/j.actamat.2015.06.063 (2015).

M. Kapoor, D. Isheim, G. Ghosh, S. Vaynman, M.E. Fine, and Y.-W. Chung, Acta Mater. 73, 56 https://doi.org/10.1016/j.actamat.2014.03.051 (2014).

H.Y. Wang, X.Y. Gao, S.M. Chen, Y.M. Li, Z.W. Wu, and H.P. Ren, J. Alloys Compd. 846, 156386 https://doi.org/10.1016/j.jallcom.2020.156386 (2020).

S. Shojai, P. Schaumann, M. Braun, and S. Ehlers, Int. J. Fatigue 164, 107128 https://doi.org/10.1016/j.ijfatigue.2022.107128 (2022).

M. Morcillo, I. Díaz, H. Cano, B. Chico, and D. de la Fuente, Constr. Build. Mater. 213, 723 https://doi.org/10.1016/j.conbuildmat.2019.03.334 (2019).

Q.F. Xu, K.W. Gao, W.T. Lv, and X.L. Pang, Corros. Sci. 102, 114 https://doi.org/10.1016/j.corsci.2015.09.025 (2016).

K.W. Chen, J.Z. Yan, N. Li, M.L. Luo, H.J. Shi, X. Zhu, Y. Liu, X.C. Zhao, and R. Zhang, J. Alloys Compd. 815, 152429 https://doi.org/10.1016/j.jallcom.2019.152429 (2020).

N. Ochoa, E. Mardaras, R. González-Martínez, and G. Artola, Corros. Sci. 206, 110480 https://doi.org/10.1016/j.corsci.2022.110480 (2022).

W.B. Dai, C. Zhang, L.J. Zhao, and C.Y. Li, Mater. Today Commun. 33, 104195 https://doi.org/10.1016/j.mtcomm.2022.104195 (2022).

A. Weisenburger, G. Müller, A. Heinzel, A. Jianu, H. Muscher, and M. Kieser, Nucl. Eng. Des. 241, 1329 https://doi.org/10.1016/j.nucengdes.2010.08.005 (2011).

B. Lv, Z.M. Zhang, Z.N. Yang, F.C. Zhang, C.L. Zheng, and Y.R. He, Mater. Lett. 173, 95 https://doi.org/10.1016/j.matlet.2016.02.148 (2016).

A. Qaban, T. Mohmed, M.M. Quazi, and S. Naher, Mater. Today Commun. 25, 101362 https://doi.org/10.1016/j.mtcomm.2020.101362 (2020).

R. Priya, S. Ningshen, M. Sakairi, and S. Ukai, J. Nucl. Mater. 534, 152120 https://doi.org/10.1016/j.jnucmat.2020.152120 (2020).

L. Zhang, D. Niu, B. Wen, G. Peng, and Z. Sun, Constr. Build. Mater. 258, 119564 https://doi.org/10.1016/j.conbuildmat.2020.119564 (2020).

H. Wang, H. Yu, S. Kondo, N. Okubo, and R. Kasada, Corros. Sci. 175, 108864 https://doi.org/10.1016/j.corsci.2020.108864 (2020).

T. Kosaba, I. Muto, and Y. Sugawara, Corros. Sci. 179, 109145 https://doi.org/10.1016/j.corsci.2020.109145 (2021).

X.X. Xu, T.Y. Zhang, W. Wu, S. Jiang, J.W. Yang, and Z.Y. Liu, Constr. Build. Mater. 279, 122341 https://doi.org/10.1016/j.conbuildmat.2021.122341 (2021).

Y. Tang, B. Li, G.F. Zhang, P.F. Ji, X.Y. Zhang, M.Z. Ma, and R.P. Liu, Mater. Lett. 320, 132286 https://doi.org/10.1016/j.matlet.2022.132286 (2022).

G. Han, Z.J. Xie, Z.Y. Li, B. Lei, C.J. Shang, and R.D.K. Misra, Mater. Des. 135, 92 https://doi.org/10.1016/j.matdes.2017.08.054 (2017).

Z.M. Pan, H. Luo, Q.C. Zhao, H.X. Cheng, Y. Wei, X.F. Wang, B.W. Zhang, and X.G. Li, Corros. Sci. 207, 110570 https://doi.org/10.1016/j.corsci.2022.110570 (2022).

H. Luo, Z.M. Li, A.M. Mingers, and D. Raabe, Corros. Sci. 134, 131 https://doi.org/10.1016/j.corsci.2018.02.031 (2018).

J. Wang, L.Y. Sun, H.C. Ma, X.Q. Cheng, and X.G. Li, Mater. Sci. Eng. A 853, 143771 https://doi.org/10.1016/j.msea.2022.143771 (2022).

Y.L. Zhou, X.J. Zhang, T. Jia, and Z.Y. Liu, J. Iron Steel Res. Int. 22, 496 https://doi.org/10.1016/S1006-706X(15)30032-7 (2015).

X.X. Dong and Y.F. Shen, Mater. Sci. Eng. A 852, 143737 https://doi.org/10.1016/j.msea.2022.143737 (2022).

R. Shi, Y. Tu, K. Gao, L. Qiao, and X. Pang, Corros. Commu. 5, 14 https://doi.org/10.1016/j.corcom.2021.11.006 (2022).

W.H. Huang, H.W. Yen, and Y.L. Lee, J. Mater. Res. Technol. 8, 1476 https://doi.org/10.1016/j.jmrt.2018.11.002 (2019).

G. Li, L. Wang, H. Wu, C. Liu, X. Wang, and Z. Cui, Corros. Sci. 174, 108815 https://doi.org/10.1016/j.corsci.2020.108815 (2020).

Z.L. Li, K. Xiao, C.F. Dong, X.Q. Cheng, W. Xue, W. Yu, and J. Iron, Steel Res. Int. 26, 1315 https://doi.org/10.1007/s42243-019-00316-9 (2019).

A.K. AceroGutiérrez, A.L. Pérez-Flores, J.G. Godínez-Salcedo, J. Moreno-Palmerin, and Á.D.J. Morales-Ramírez, Coatings 10, 385 https://doi.org/10.3390/coatings10040385 (2020).

G.P. Singh, A.P. Moon, S. Sengupta, G. Deo, S. Sangal, and K. Mondal, J. Mater. Eng. Perform. 24, 1961 https://doi.org/10.1007/s11665-015-1448-7 (2015).

F. Pastorek, K. Borko, S. Fintova, D. Kajanek, and B. Hadzima, Coatings 6, 46 https://doi.org/10.3390/coatings6040046 (2016).

Q. Zhao, Int. J. Electrochem. Sci. 12, 7989 https://doi.org/10.20964/2017.09.35 (2017).

R. Wang, S. Luo, M. Liu, and Y. Xue, Corros. Sci. 85, 270 https://doi.org/10.1016/j.corsci.2014.04.023 (2014).

J. Soltis, Corros. Sci. 90, 5 https://doi.org/10.1016/j.corsci.2014.10.006 (2015).

G.S. Frankel, J. Electrochem. Soc. 145, 2186 https://doi.org/10.1149/1.1838615 (2019).

M.H. Sun, C.W. Du, Z.Y. Liu, C. Liu, X.G. Li, and Y.M. Wu, Corros. Sci. 186, 109427 https://doi.org/10.1016/j.corsci.2021.109427 (2021).

J.F. Moulder, W.F. Stickle, W.M. Sobol and K.D. Bomben, (1992).

Z.L. Xu, H. Zhang, X.J. Du, Y.Z. He, H. Luo, G.S. Song, L. Mao, T.W. Zhou, and L.L. Wang, Corros. Sci. 177, 108954 https://doi.org/10.1016/j.corsci.2020.108954 (2020).

X.B. He, L.J. Wang, and K. Chou, J. Alloys Compd. 876, 160209 https://doi.org/10.1016/j.jallcom.2021.160209 (2021).

C.T. Liu and J.K. Wu, Corros. Sci. 49, 2198 https://doi.org/10.1016/j.corsci.2006.10.032 (2007).

T.E. Pou, O.J. Murphy, V. Young, J.O.M. Bockris, and L.L. Tongson, J. Electrochem. Soc. 131, 1243 https://doi.org/10.1149/1.2115795 (1984).

Z. Zeng, M. Zhou, M. Esmaily, Y. Zhu, S. Choudhary, J.C. Griffith, J. Ma, Y. Hora, Y. Chen, A. Gullino, Q. Shi, H. Fujii, and N. Birbilis, Commu. Mater. https://doi.org/10.1038/s43246-022-00245-3 (2022).

Acknowledgements

The authors appreciate the support from the China National Key R&D Program of (2016YFB0300600).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interests to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Che, Mj., Du, Xj., Yi, S. et al. Superior Pitting Corrosion Resistance of Ultra-high Strength Low Alloy Steel Via Co-alloying Al and Cu. JOM 75, 4287–4299 (2023). https://doi.org/10.1007/s11837-023-06021-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06021-z