Abstract

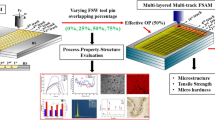

Friction stir additive manufacturing (FSAM) is a sheet-lamination based additive manufacturing technique. In addition to the traditional factors that govern the friction stir process-structure-property relationship, the processing history is convoluted by the in-plane raster pattern and repeated thermal cycling from subsequent layers. This can lead to complex thermal gradients within the workpiece and reprocessing of material. This work aims to understand the impact of raster pattern spacing and direction on the microstructure and properties during friction stir additive manufacturing of Al-5083. Control of the raster spacing can lead to an increase in hardness of up to 18% from the base material and defect-free joining. These results are then directly demonstrated at the component-scale for FSAM of Al-5083.

Similar content being viewed by others

References

N. Tuncer and A. Bose, JOM 72, 3090–3111 https://doi.org/10.1007/s11837-020-04260-y (2020).

M. Yuqing, K. Liming, H. Chunping, L. Fencheng, and L. Qiang, Int. J. Adv. Manuf. Technol. 83, 1637–1647 https://doi.org/10.1007/s00170-015-7695-9 (2016).

R.S. Mishra and Z.Y. Ma, Mater. Sci. Eng. R. Rep. 50, 1–78 https://doi.org/10.1016/j.mser.2005.07.001 (2005).

S. Palanivel, H. Sidhar, and R.S. Mishra, JOM 67, 616–621 https://doi.org/10.1007/s11837-014-1271-x (2015).

S. Palanivel, P. Nelaturu, B. Glass, and R.S. Mishra, Mater. Des. 1980–2015(65), 934–952 https://doi.org/10.1016/j.matdes.2014.09.082 (2015).

A. Silva-Magalhães, J. De Backer, J. Martin, and G. Bolmsjö, J. Manuf. Process. 39, 12–17 https://doi.org/10.1016/j.jmapro.2019.02.001 (2019).

W. Woo, Z. Feng, X.L. Wang, D.W. Brown, B. Clausen, K. An, H. Choo, C.R. Hubbard, and S.A. David, Sci. Technol. Weld. Join. 12, 298–303 https://doi.org/10.1179/174329307X197548 (2007).

R. Kumar, V. Pancholi, and R.P. Bharti, J. Mater. Process. Technol. 255, 470–476 https://doi.org/10.1016/j.jmatprotec.2017.12.034 (2018).

A. Fehrenbacher, N.A. Duffie, N.J. Ferrier, F.E. Pfefferkorn, and M.R. Zinn, Int. J. Adv. Manuf. Technol. 71, 165–179 https://doi.org/10.1007/s00170-013-5364-4 (2014).

K. Ross, G. Grant, J. Darsell, and D. Catalini, In Friction Stir Welding and Processing IX, ed. Y. Hovanski, R. Mishra, Y. Sato, P. Upadhyay and D. Yan (Springer International Publishing: Cham, 2017), pp 269-275.

K. Kumar Jha, R. Kesharwani, and M. Imam, Mater. Today Proc. 56, 819–825 https://doi.org/10.1016/j.matpr.2022.02.262 (2022).

J. Mohammadi, Y. Behnamian, A. Mostafaei, H. Izadi, T. Saeid, A.H. Kokabi, and A.P. Gerlich, Mater. Charact. 101, 189–207 https://doi.org/10.1016/j.matchar.2015.01.008 (2015).

A.J. Barnes, H. Raman, A. Lowerson, and D. Edwards, Mater. Sci. Forum 735, 361–371 https://doi.org/10.4028/www.scientific.net/msf.735.361 (2012).

Y. Ding, J.A. Muñiz-Lerma, M. Trask, S. Chou, A. Walker, and M. Brochu, MRS Bull. 41, 745–751 https://doi.org/10.1557/mrs.2016.214 (2016).

M. Köhler, S. Fiebig, J. Hensel, and K. Dilger, Metals. https://doi.org/10.3390/met9050608 (2019).

B.J. Phillips, C.J. Williamson, R.P. Kinser, J.B. Jordon, K.J. Doherty, and P.G. Allison, Materials. https://doi.org/10.3390/ma14216732 (2021).

Y. Li, B. Yang, M. Zhang, H. Wang, W. Gong, R. Lai, Y. Li, and J. Teng, Corros. Sci. 213, 110972 https://doi.org/10.1016/j.corsci.2023.110972 (2023).

J. Gandra, R.M. Miranda, and P. Vilaça, Mater. Sci. Eng. A 528, 5592–5599 https://doi.org/10.1016/j.msea.2011.03.105 (2011).

Z. Zhang, Z.J. Tan, J.Y. Li, Y.F. Zu, W.W. Liu, and J.J. Sha, Int. J. Adv. Manuf. Technol. 104, 767–784 https://doi.org/10.1007/s00170-019-03917-6 (2019).

K.J. Al-Fadhalah, A.I. Almazrouee, and A.S. Aloraier, Mater. Des. 53, 550–560 https://doi.org/10.1016/j.matdes.2013.07.062 (2014).

M.V.N.V. Satyanarayana, K. Adepu, and K. Chauhan, Met. Mater. Int. 27, 3563–3573 https://doi.org/10.1007/s12540-020-00757-y (2021).

C.B. Fuller, M.W. Mahoney, W.H. Bingel, M. Calabrese, and B. London, Mater. Sci. Forum 539–543, 3751–3756 https://doi.org/10.4028/www.scientific.net/MSF.539-543.3751 (2007).

T. Jiang, T. Jiao, G. Dai, Z. Shen, Y. Guo, Z. Sun, and W. Li, J. Alloys Compd. 935, 1680–19 https://doi.org/10.1016/j.jallcom.2022.168019 (2023).

Y.S. Sato, M. Urata, H. Kokawa, and K. Ikeda, Mater. Sci. Eng. A 354, 298–305 https://doi.org/10.1016/S0921-5093(03)00008-X (2003).

W.J. Arbegast, Scr. Mater. 58, 372–376 https://doi.org/10.1016/j.scriptamat.2007.10.031 (2008).

E. Salari, M. Jahazi, A. Khodabandeh, and H. Ghasemi-Nanesa, Mater. Des. 58, 381–389 https://doi.org/10.1016/j.matdes.2014.02.00 (2014).

Acknowledgements

Pacific Northwest National Laboratory (PNNL) is operated by Battelle Memorial Institute for the DOE under Contract DEAC05-76RL01830. The authors are thankful for the financial support from the DEVCOM-Army Research Laboratory through the W911NF2020256 Grant. Usage of the microscopy facility at the Advanced Materials Engineering Research Institute (AMERI)-Florida International University is recognized for the research reported in the study.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Garcia, D., Wang, T., Sarvesha, R. et al. Investigation of Raster Pattern Spacing and Direction for Friction Stir Additive Manufacturing of Al-5083. JOM 75, 4223–4230 (2023). https://doi.org/10.1007/s11837-023-06017-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-06017-9