Abstract

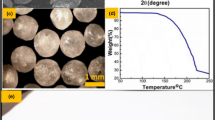

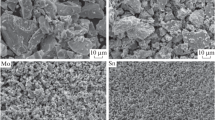

Using carbamide granules as the pore-making agent, Zn-xMg alloys (x = 0 wt.%, 5 wt.%, 10 wt.%, 15 wt.%, 20 wt.%) foams with open-cell structures (porous Zn alloys) and porosity of 50 % were fabricated by means of reactive sintering powder metallurgy. The effect of Mg on the cell wall microstructures, compositions, and compression behaviors of porous Zn alloys were investigated. The results show that sintering at a temperature of 350°C can make Zn react with Mg to form intermetallics/solution, leading to effectively establishing the metallurgical bonding. When a proper Mg was added, the formed intermetallics are beneficial for improving the compression yield strength of porous Zn alloys, but too high Mg addition leads to compression strength decrease. The porous Zn-10 wt.% Mg alloy possesses the best compression property, whose compression strength is 12.4 MPa and Young’s modulus is 0.332 GPa. The fabricated porous Zn alloys possess comparable mechanical properties with those of cancellous bones, whose compression strength and Young’s modulus are 7–10 MPa and 0.259–0.332 GPa, respectively.

Similar content being viewed by others

References

T. Wu, S.H. Yu, D.K. Chen, and Y.E. Wang, Materials 10, 1187 (2017).

S.O. Agbedor, D.H. Yang, J. Cao, J.Q. Chen, B. Saleh, C. Qiu, L. Wang, J.H. Jiang, and A.B. Ma, J. Iron Steel Res. Int. 29, 371 (2022).

Q.S. Dong, Y. Li, H.Q. Jiang, X.X. Zhou, H. Liu, M.M. Lu, C.L. Chu, F. Xue, and J. Bai, J. Magnes. Alloys 9, 1329 (2021).

D.D. Xia, Y. Qin, H. Guo, P. Wen, H. Lin, M. Voshage, J.H. Schleifenbaum, Y. Cheng, and Y.F. Zheng, Bioact. Mater. 19, 12 (2023).

I. Cockerill, Y.C. Su, S. Sinha, Y.X. Qin, Y.F. Zheng, M.L. Young, and D.H. Zhu, Mater. Sci. Eng. C 110, 110738 (2020).

M. Voshage, S. Megahed, P.G. Schückler, P. Wen, Y. Qin, L. Jauer, R. Poprawe, and J. Henrich Schleifenbaum, Mater. Today Commun. 32, 103805 (2022).

P. Wen, Y. Qin, Y.Z. Chen, M. Voshage, L. Jauer, R. Poprawe, and J.H. Schleifenhaum, J. Mater. Sci. Technol. (Shenyang, China) 35, 368 (2019).

S. Qiu, F.D. Sun, C. You, C.K. Tang, B.L. Zhou, S.Q. Zhang, J.T. Feng, A.X. Tian, and M.F. Chen, Mater. Today Commun. 35, 105605 (2023).

H.Z. Ren, C. Pan, Y.C. Liu, D.B. Liu, X.H. He, X.H. Li, and X.H. Sun, Mater. Chem. Phys. 289, 126458 (2022).

L. Zhao, Z. Zhang, Y.T. Song, S.J. Liu, Y.M. Qi, X. Wang, Q.Z. Wang, and C.X. Cui, Mate. Des. 108, 136 (2016).

D. Wang, X. Zhang, Zu. Guyin, A. Qiao, Y. He, and Mu. Yongliang, Mater. Res. Express 6, 115406 (2019).

J.A. Liu, L.R. Zhang, S.J. Liu, Z.W. Han, and Z.Q. Dong, Mater. Charact. 159, 110045 (2020).

A. Jinnapat and A. Kennedy, Metals 2, 22 (2012).

G.A. Lara-Rodriguez, I.A. Figueroa, M.A. Suarez, O. Novelo-Peralta, I. Alfonso, and R. Goodall, J. Mater. Process. Technol. 243, 16 (2017).

E. Dayaghi, H.R. Bakhsheshi-Rad, E. Hamzah, A. Akhavan-Farid, A.F. Ismail, M. Aziz, and E. Abdolahi, Mater. Sci. Eng. C 102, 53 (2019).

D.H. Yang, J.Q. Chen, J. Cao, and L. Wang, J. Mater. Eng. Perform. https://doi.org/10.1007/s11665-023-07989-0 (2023).

E.W. Andrew, G. Gioux, P. Onck, and L.J. Gibson, Int. J. Mech. Sci. 43, 701 (2001).

Z.C. Chen, T. Takeda, and K. Ikeda, Compos. Sci. Technol. 68, 2245 (2008).

D.J. Hu, J. Zhang, R.Y. Hang, C.L. Li, Y.H. Sun, X.H. Yao, and R.Q. Hang, Mater. Lett. 251, 30 (2019).

O. Smorygo, A. Marukovich, V. Mikutski, V. Stathopoulous, S. Hryhoryeu, and V. Sadykov, Front. Mater. Sci. 10, 157 (2016).

R. Murugan and S. Ramakrishna, Compos. Sci. Technol. 65, 2385 (2005).

A.P. Francis, A.R. Augustus, S. Chandramohan, S.A. Bhat, V.V. Priya, and R. Rajagopalan, Mater. Today Commun. 34, 105124 (2023).

Acknowledgements

This work is supported by the Natural Science Foundation of China (Grant. No. 12072105), the Basic Science Research Project of Nantong of China (Grant No. JC2021190), the Natural Science Foundation of Jiangsu Province of China (Grant. No. BK20171437).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, D., Hong, X., Chen, J. et al. Effect of Mg on Compression Property of Porous Zn Alloys Fabricated by Low-Temperature Reactive Sintering Powder Metallurgy Approach. JOM 75, 5341–5349 (2023). https://doi.org/10.1007/s11837-023-05976-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05976-3