Abstract

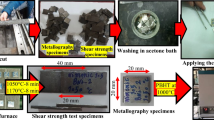

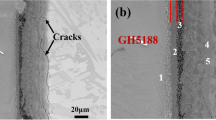

Two different filler metals were used for vacuum brazing of NIMONIC 105 similar joints. At first, the specimen was brazed using BNi-2 as filler. The optimized parameters were brazing time and temperature of 7 min and 1200°C, respectively. Then, the innovative approach of adding tungsten to the braze filler was adopted to improve the metallurgical properties of the joints. The formation of intermetallic and eutectic phases was investigated by back-scattered electron (BSE) imaging, energy dispersive X-ray spectroscopy (EDS), X-ray diffraction (XRD), and hardness testing. The investigation confirmed that, unlike the bulky brittle phases (SiCr3, Ni2B, Cr2B, and NiSi), and network or eutectic phases found in the specimen brazed using BNi-2 as filler, a W-rich filler (BNi-10) creates fine precipitates (CrSi2, Cr2B) that have minimal impact on the properties of the joint. Microhardness evaluation indicated that using the BNi-10 filler resulted in more uniform hardness profiles across the joint. The shear strength of brazed joints increased significantly from 81.8 MPa to 88.1 MPa with the addition of tungsten. Lack of Ni2B and NiSi formation resulted in a high ductility of 17.1% in the specimen brazed via BNi-10 when compared with 10.95% in the specimen brazed via BNi-2.

Similar content being viewed by others

References

Y. Zhua, Z. Zhua, Z. Xianga, Z. Yinb, Z. Wua, and W. Yana, J. Alloys Compd. 476, 341 https://doi.org/10.1016/j.jallcom.2008.08.062 (2009).

R. Barazandeh, M.A. Mofid, M. Jafarzadegan, and H. Nasiri Vatan, Weld. World. https://doi.org/10.1007/s40194-022-01460-9 (2023).

R.C. Reed, The superalloys—fundamentals and applications (Cambridge University Press, New York, 2006).

M. Naalchian, M. Kasiri-Asgarani, M. Shamanian, R. Bakhtiari, and H.R. Bakhsheshi-Rad, J. Mater. Res. Technol. 13, 2144 https://doi.org/10.1016/j.jmrt.2021.05.069 (2021).

F. Arhami, S.E. Mirsalehi, and A. Sadeghian, J. Mater. Process. Technol. 265, 219 https://doi.org/10.1016/j.jmatprotec.2018.10.021 (2019).

W. Li, T. Jin, X. Sun, Y. Guo, H. Guan, and Z. Hu, Scr. Mater. 48(9), 1283 (2003).

J. Liu, T. Jin, N. Zhao, Z. Wang, X.F. Sun, H.R. Guan, and Z.Q. Hu, Mater. Sci. Forum 546, 1245 (2007).

M. Khakian, S. Nategh, and S. Mirdamadi, J. Alloys Compd. 653, 386 https://doi.org/10.1016/j.jallcom.2015.09.044 (2015).

N. Wu, Y.J. Li, and Q.S. Ma, Mater. Des. 53, 816 https://doi.org/10.1016/j.matdes.2013.07.063 (2014).

M.A. Mofid, and P. Lotfipoornasaji, J. Met. Mater. Miner. 31, 51 https://doi.org/10.14456/jmmm.2021.7 (2021).

M.A. Mofid, M. Farshbaf, and H. Naeimian, Mater. Perform. Charact. 10(1), 285 https://doi.org/10.1520/MPC20200027 (2021).

M.A. Mofid, and A. Mahdavi Nejad, Mater. Chem. Phys. 263, 124404 (2021).

M.A. Mofid, H. Naeimian, M. Hajian Heidary, and M. Farshbaf, J. Adv. Mater. Process. 8(1), 55 (2020).

H. Naeimian, and M.A. Mofid, Trans. Nonferrous Met. Soc. China 30, 1267 https://doi.org/10.1016/S1003-6326(20)65294-3 (2020).

H. Shakeri, and M.A. Mofid, Met. Mater. Int. 27, 4132 https://doi.org/10.1007/s12540-020-00731-8 (2021).

H. Naeimian, and M.A. Mofid, Int. J. Mater. Res. 111, 424 https://doi.org/10.3139/146.111902 (2020).

M.A. Mofid, and E. Loryaei, Mater. Werkst. 51, 413 (2020).

M.A. Mofid, and E. Loryaei, J. Mater. Res. Technol. 8(5), 3872 (2019).

D. McGuire, X. Huang, D. Nagy, and W. Chen, J. Eng. Gas Turbines Power 132, 062101 https://doi.org/10.1115/1.4000136 (2010).

M.A. Arafin, M. Medraj, D.P. Turner, and P. Bocher, Mater. Chem. Phys. 106(1), 109 (2007).

J. Ruiz-Vargas, N. Siredey-Schwaller, N. Gey, P. Bocher, and A. Hazotte, J. Mater. Process. Technol. 213(1), 20 (2013).

X. Huang, and W. Miglietti, J. Eng. Gas Turbines Power 13, 010801–010811 (2012).

D. Liu, Y. Song, B. Shi, Q. Zhang, X. Song, H. Niu, and J. Feng, J. Mater. Sci. Technol. 34(10), 1843–1850 https://doi.org/10.1016/j.jmst.2018.02.008 (2018).

H.M. Hdz-García, A.I. Martinez, R. Munoz-Arroyo, J.L. Acevedo-Dávila, F. García-Vázquez, and F.A. Reyes-Valdes, Mater. Sci. Technol. 30, 259 (2014).

J. Shen, Y.C. Liu, Y.J. Han, Y.M. Tian, and H.X. Gao, J. Electron. Mater. 35, 1672 (2006).

M. Durand-Charre, The microstructure of superalloys (CRC Press, 1997).

C.T. Sims, Superalloys 1984, 399 (1984).

C. Hawk, Wide gap braze repairs of nickel superalloy gas turbine components, (Colorado School of Mines, Golden, Colorado, 2016)

ASTM standard D1002, Standard test method for apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading (metal-to-metal) [S] (1999)

O.A. Idowu, O.A. Ojo, and M.C. Chaturvedi, Metall. Mater. Trans. A 37A, 2787 (2006).

Y. Xu, X. Qiu, S. Wang, C. Luo, Y. Lu, and F. Xing, Vacuum 184, 109793 (2021).

ASM Handbook, Alloy phase diagrams, 10th edn. (ASM Handbook, 1992), pp. 283–292

P. Sung, and D. Poirier, Metall. Mater. Trans. A 30(8), 2173 (1999).

Y.H. Kim, K.T. Kim, and I.H. Kim, Key Eng. Mater. 306–308, 935 (2006).

T.B. Massalski, H. Okamoto, P.R. Subramanian, and L. Kacprzak, Binary alloy phase diagrams (ASM International, 1990), p2883.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Mofid, M.A., Barazandeh, R. & Jafarzadegan, M. Vacuum Brazing of NIMONIC 105 Superalloy Using W-Rich BNi-10 and Conventional BNi-2 Fillers. JOM 75, 4749–4761 (2023). https://doi.org/10.1007/s11837-023-05944-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05944-x