Abstract

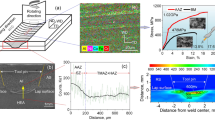

The content of Ce plays an important role in balancing the strength and plasticity of Al-Ce alloys, because it seriously affects the morphology and distribution of Ce-rich phase. Electromagnetic stirring (EMS) is an effective process for controlling Ce-rich phase. The effects of EMS on Ce-rich phase in hypoeutectic, eutectic and hypereutectic Al-Ce alloys were mainly studied. The results show that eutectic Al11Ce3 phase transits from lamellar-like to fibrous-like in Al-8Ce alloy and Al-12Ce alloy after EMS. The refinement of the lamellar spacings and eutectic Al11Ce3 fibres is insignificant, and the effect of load transfer strengthening and grain refining strengthening is unsatisfactory. Coarser primary Al11Ce3 phase is broken and eutectic Al11Ce3 phase is refined and spheroidized in Al-14Ce alloy after EMS. The lamellar spacing and eutectic Al11Ce3 fibre size greatly decrease in Al-14Ce alloy, from 2.14 μm to 1.28 μm and 0.94 μm to 0.43 μm, respectively. The load transfer strengthening and fine grain strengthening are enhanced. The tensile strength increases from 116.8 MPa to 184.6 MPa, the yield strength increases from 74.5 MPa to 107.6 MPa, and the elongation increases from 1.4% to 7.1%. This reflects that EMS play a more beneficial role in Al-14Ce alloy.

Similar content being viewed by others

References

Z.C. Sims, D. Weiss, S.K. McCall, M.A. Mcguirer, T. Ott, T. Geer, O. Rios, and P.A.E. Turchi, JOM 68, 1940 (2016).

E.E. Moore, P.E.A. Turchi, V. Lordi, D. Weiss, Z.C. Sims, H.B. Henderson, M.S. Kesler, O. Rios, S.K. McCall, and A. Perron, J. Phase Equilib. Diffus. 41(6), 764 (2020).

N. Belov, A. Aksenov, and D. Eskin, Iron in Aluminum Alloys: Impurity and Alloying Element (Taylor and Francis, Abingdon, 2002).

N. Belov, and A. Khvan, Acta Mater. 55(16), 5473 (2007).

V. Zolotorevsky, N. Belov, and M. Glasoff, Casting Aluminum Alloys (Elsevier, Amsterdam, 2007).

F. Czerwinski, J. Mater. Sci. 55(12), 24 (2020).

T. Koutsoukis, and M. Makhlouf, Int. J. Metalcast. 10, 342 (2016).

K. Gschneidner, and M. Verkande, Selected Cerium Phase Diagrams (Iowa State University of Science and Technology, Ames, 1974).

W. Cai, J. Mater. Sci. Lett. 16(22), 1824 (1997).

F. Czerwinski, Mater. Sci. Eng., A 13, 3441 (2020).

D. Weiss, J. Mater. Eng. Perform. 28(4), 1903 (2019).

J. Zhang, and H.Z. Fu, Chin. J. Mater. Res. 11(6), 612 (1997).

W. Weng, Study on the Action of 6063 and ZL102 Aluminum Alloys in the Traveling Magnetic Field (Fuzhou University, Fuzhou, 2006).

B.G. Mi, J. Wang, L.J. He, and P.J. Li, Foundry 01, 16 (2010).

Q. Lan, Q.C. Le, Q.Y. Liao, L. Bao, J.F. Zhang, and J.Z. Cui, Mater. Chem. Phys. 214, 383 (2018).

L. Wang, R. Qi, B. Ye, Y. Bai, R. Huang, H.Y. Jiang, and W.J. Ding, Metall. Mater. Trans. A. 51(5), 1972 (2020).

J.Y. Ye, K. Dai, Z.G. Wang, J.Q. Chen, M.Q. Gao, and R.G. Guan, Mater. Sci. Eng., A 835, 142611 (2022).

Y. Kishida, K. Takeda, I. Miyoshino, and E. Takeuchi, ISIJ Int. 30(1), 34 (1990).

X.L. Zhang, D.H. Mao, and Q.G. Chen, Trans. Nonferr. Metals Soc. China 5(4), 145 (1995).

C.Y. Ban, Q.X. Ba, L.Y. Zhu, and J.Z. Cui, J. North-East. Univ. (Nat. Sci.) 24(5), 482 (2003).

A. Plotkowski, O. Rios, N. Sridharan, Z. Sims, K. Unocic, R.T. Ott, R.R. Dehoff, and S.S. Babu, Acta Mater. 126(16), 507 (2017).

R. Dasgupta, J. Mater. Process. Technol. 72(3), 380 (1997).

P.J. Li, D.B. Zeng, J. Jia, and Q.C. Li, Foundry 06, 12 (1997).

D. Feng, and G.J. Jin, New Theory of Condensed Matter Physics (Shanghai Science and Technology Press, Shanghai, 1992).

C. Zhang, Y.F. Wang, H.Y. Lv, X.P. Wang, Y.Q. Sun, X.D. Wang, J. Ye, Y.W. Sun, Y. Yu, F.Q. Jiang, J. Li, and Y.R. Liu, Mater. Sci. Eng., A 821, 0921 (2021).

Y. Liu, R.A. Michi, and D.C. Dunand, Mater. Sci. Eng.: A 767, 0921 (2019).

T. Wu, A. Plotkowski, A. Shyam, and D.C. Dunand, Mater. Sci. Eng., A 833, 0921 (2022).

S.S. Li, A.M. Zhao, W.M. Mao, X.Y. Zhong, and Y.F. Han, Acta Met. Sin. 36(5), 545 (2000).

Y. He, X.J. Yang, Y.B. Zhu, and X.K. Zhang, Chin. J. Rare Met. 42(4), 350 (2018).

N. Petch, J. Iron Steel Inst. 174, 25 (1953).

E. Hall, Proc. Phys. Soc. B 64(9), 747 (1951).

N. Hansen, Acta Metall. 25(8), 863 (1977).

N. Hansen, Scr. Mater. 51(8), 801 (2004).

D.A. Porter, K.E. Easterling, and G.D.W. Smith, Acta Metall. 26(9), 1405 (1978).

J.D. Embury, and R.M. Fisher, Acta Metall. 14(2), 147 (1966).

Z.Q. Tan, Z.Z. Chen, G.L. Fan, J. Gang, Z. Jie, R. Xu, A. Shan, Z. Li, and Z. Di, Mater. Des. 90, 845 (2016).

H.R. Xu, and Q.Z. Li, Mater. Sci. Eng., A 706, 249 (2017).

G.Q. Wu, Q.Q. Zhang, X. Yang, Z. Huang, and W. Sha, Compos. Interfaces 21(5), 415 (2014).

L.J. Huang, L. Geng, H.X. Peng, and B. Kaveendran, Mater. Sci. Eng., A 534, 688 (2012).

Acknowledgements

This work was supported by the Program of Qingjiang Excellent Young Talents (Grant No. JXUSTQJBJ2020007), the Science and Technology Project of the Education Department of Jiangxi Province (Grant No. GJJ200847) and the Graduate Innovation Special Fund Project of Jiangxi Province in 2021 (Grant No. YC2021-S567).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All the authors listed have approved the manuscript. We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work; there is no professional or other personal interest of any nature or kind in any product.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dai, K., Ye, J., Wang, Z. et al. Beneficial Utilization of Electromagnetic Stirring Technology in Al-Ce Alloys. JOM 75, 2788–2798 (2023). https://doi.org/10.1007/s11837-023-05904-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05904-5