Abstract

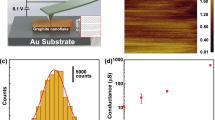

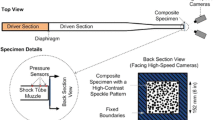

Owing to the opaque nature of the laminated structures, traditional high-speed optical camera cannot be used to detect the dynamic process of sub-surface deformation. In this article, we report a study of using high speed X-ray imaging to study the high strain rate deformation in laminated Al structures. We used a Kolsky bar apparatus to apply dynamic compression and a high-speed synchrotron X-ray phase contrast imaging (PCI) setup to conduct the in situ X-ray imaging study. The in situ X-ray imaging captures the shock wave propagation in the laminated structures. After shock compression, we characterized the microstructures by using transmission electron microscopy (TEM), which demonstrates an increase of dislocation density. The micro-pillar compression tests show that the yield strength at 0.2% offset of laminated Al-graphene composite has a significant increase of 67%, from 30 to 50 MPa, compared to laminate Al after shock loading.

Similar content being viewed by others

References

N.A. Mara, C.A. Bronkhorst and I.J. Beyerlein, Los Alamos National Lab.(LANL), Los Alamos, NM (United States) 2015.

E. Bringa, K. Rosolankova, R. Rudd, B. Remington, J. Wark, M. Duchaineau, D. Kalantar, J. Hawreliak, and J. Belak, Nat. Mater. 5, 805–809 (2006).

W.W. Chen, M.C. Hudspeth, B. Claus, N.D. Parab, J.T. Black, K. Fezzaa, and S.N. Luo, Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 372, 20130191 https://doi.org/10.1098/rsta.2013.0191 (2014).

N.D. Parab, J.T. Black, B. Claus, M. Hudspeth, J. Sun, K. Fezzaa, and W.W. Chen, Int. J. Appl. Glass Sci. 5, 363–373 https://doi.org/10.1111/ijag.12092 (2014).

M.B. Zbib, N.D. Parab, W.W. Chen, and D.F. Bahr, Powder Technol. 283, 57–65 https://doi.org/10.1016/j.powtec.2015.04.066 (2015).

N.D. Parab, Z.A. Roberts, M.H. Harr, J.O. Mares, A.D. Casey, I.E. Gunduz, M. Hudspeth, B. Claus, T. Sun, K. Fezzaa, S.F. Son, and W.W. Chen, Appl. Phys. Lett. 109, 131903 https://doi.org/10.1063/1.4963137 (2016).

N.D. Parab, Z. Guo, M. Hudspeth, B. Claus, B.H. Lim, T. Sun, X. Xiao, K. Fezzaa, and W.W. Chen, Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 375, 20160178 https://doi.org/10.1098/rsta.2016.0178 (2017).

Z. Guo, M.J. Forrestal, S. Martinez-Morales, and W. Chen, J. Dyn. Behav. Mater. 5, 409–415 https://doi.org/10.1007/s40870-019-00200-3 (2019).

N. Kedir, C.D. Kirk, Z. Guo, N.E. Kerschen, T. Sun, K. Fezzaa, and W. Chen, Int. J. Impact Eng. 129, 168–179 https://doi.org/10.1016/j.ijimpeng.2019.01.012 (2019).

N.E. Kerschen, C.J. Sorensen, Z. Guo, J.O. Mares, K. Fezzaa, T. Sun, S.F. Son, and W.W. Chen, Propellants Explos. Pyrotech. 44, 447–454 https://doi.org/10.1002/prep.201800002 (2019).

J.O. Mares, Z.A. Roberts, I. EmreGunduz, N.D. Parab, T. Sun, K. Fezzaa, W.W. Chen, S.F. Son, and J.F. Rhoads, Appl Mater Today 15, 286–294 https://doi.org/10.1016/j.apmt.2019.01.009 (2019).

N.D. Parab, L. Xiong, Q. Guo, Z. Guo, C. Kirk, Y. Nie, X. Xiao, K. Fezzaa, W. Everheart, W.W. Chen, L. Chen, and T. Sun, Addit. Manufact. 30, 100878 https://doi.org/10.1016/j.addma.2019.100878 (2019).

X. Zhai, J. Gao, H. Liao, C.D. Kirk, Y.A. Balogun, and W.W. Chen, Int. J. Impact Eng. 129, 112–118 https://doi.org/10.1016/j.ijimpeng.2019.03.002 (2019).

X. Zhai, J. Gao, Y. Nie, Z. Guo, N. Kedir, B. Claus, T. Sun, K. Fezzaa, X. Xiao, and W.W. Chen, J. Mech. Phys. Solids 131, 358–371 https://doi.org/10.1016/j.jmps.2019.07.010 (2019).

X. Zhai, Z. Guo, J. Gao, N. Kedir, Y. Nie, B. Claus, T. Sun, X. Xiao, K. Fezzaa, and W.W. Chen, Acta Biomater. 90, 278–286 https://doi.org/10.1016/j.actbio.2019.03.045 (2019).

N. Kedir, E. Garcia, C. Kirk, Z. Guo, J. Gao, X. Zhai, T. Sun, K. Fezzaa, S. Sampath, and W.W. Chen, J Am Ceramic Soc 103, 4586–4601 https://doi.org/10.1111/jace.17165 (2020).

X. Zhai, E.A. Nauman, D. Moryl, R. Lycke, and W.W. Chen, J. Mech. Behavior Biomed. Mater. 103, 103597 https://doi.org/10.1016/j.jmbbm.2019.103597 (2020).

J. Wang, and A. Misra, Curr. Opin. Solid State Mater. Sci. 15, 20–28 https://doi.org/10.1016/j.cossms.2010.09.002 (2011).

X. Liu, F. Wang, H. Wu, and W. Wang, Appl. Phys. Lett. 104, 231901 (2014).

G.T. Gray, and J.C. Huang, Mater. Sci. Eng. A 145, 21–35 https://doi.org/10.1016/0921-5093(91)90292-U (1991).

M. Yang, Y. Liu, T. Fan, and D. Zhang, Prog. Mater. Sci. 110, 100652 https://doi.org/10.1016/j.pmatsci.2020.100652 (2020).

S. Gadipelli, and Z.X. Guo, Prog. Mater. Sci. 69, 1–60 https://doi.org/10.1016/j.pmatsci.2014.10.004 (2015).

Acknowledgements

This research used resources of the Advanced Photon Source, a US Department of Energy (DOE) Office of Science User Facility operated for the DOE Office of Science by Argonne National Laboratory under Contract No. DE-AC02-06CH11357. D. L. appreciates the support from the National Science Foundation under Award No. 1943445. The in situ micromechanical tests were performed in the Nebraska Center for Materials and Nanoscience, which is supported by the National Science Foundation under Award ECCS: 1542182 and the Nebraska Research Initiative.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Yang, G., Xie, D., Nie, Y. et al. In-Situ X-Ray Imaging High Strain Rate Compression of Laminate Al-Graphene Composite and Mechanical Property Characterization. JOM 75, 3105–3110 (2023). https://doi.org/10.1007/s11837-023-05853-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05853-z