Abstract

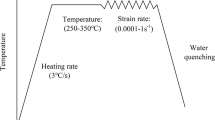

In this paper, a Cu-3.20Ni-0.61Co-0.75Si-0.19Cr-0.15 Mg (wt.%) alloy was subjected to hot compression at temperatures of 700–950°C and strain rates of 0.001–10 s−1. The constitutive equations were established using a strain-related Arrhenius model and a feed-forward artificial neural network (ANN) model. Evaluation showed that the ANN-type constitutive equation had a high Pearson correlation coefficient of 0.9997 and a low mean squared error of 2.55 MPa2; thus, it was more accurate to describe the flow behavior of the Cu-Ni-Co-Si-Cr-Mg alloy than the strain-related Arrhenius-type constitutive equation. The hot processing maps in the conditions of non-linear dissipation governed by the two constitutive equations were also established. Evaluation showed that the ANN-type hot processing maps successfully predicted unstable deformation and dynamically-recrystallized microstructure and thus had better performance than the Arrhenius-type hot processing maps. The microstructure of the Cu-Ni-Co-Si-Cr-Mg alloy after hot compression was also characterized in detail. The microstructural features were unstable deformation for the compression at 700°C and 0.001 s−1, uneven deformation for the compression at 700°C and 1 s−1, equiaxed subgrains for the compression at 950°C and 0.001 s−1 and equiaxed grains and annealing twins for the compression 950°C and 1 s−1.

Similar content being viewed by others

References

X. Wan, W. Xie, H. Chen, F. Tian, H. Wang, and B. Yang, J. Alloys Compd. 862, 158531 https://doi.org/10.1016/j.jallcom.2020.158531 (2021).

J. Dai, M. Ma, Z. Xiao, X. Meng, G. Sun, T. Zhang, T. Zhou, L. Li, and Y. Zhu, Mater. Sci. Eng.: A 833, 142511 https://doi.org/10.1016/j.msea.2021.142511 (2022).

Y. Ding, Z. Xiao, M. Fang, S. Gong and J. Dai, Mater. Sci. Eng.: A, 144603 (2023).

S. Li, M. Fang, Z. Xiao, X. Meng, Q. Lei, and Y. Jia, J. Market. Res. 22, 2222–2238 (2023).

J. Yi, Y. Jia, Y. Zhao, Z. Xiao, K. He, Q. Wang, M. Wang, and Z. Li, Acta Mater. 166, 261–270 https://doi.org/10.1016/j.actamat.2018.12.047 (2019).

Z. Liu, Y. Chen, H. Wei, and Z. Li, Mater. Lett. 236, 292–294 https://doi.org/10.1016/j.matlet.2018.10.128 (2019).

H. Kim, J.H. Ahn, S.Z. Han, J. Jo, H. Baik, M. Kim, and H.N. Han, J. Alloys Compd. 832, 155059 https://doi.org/10.1016/j.jallcom.2020.155059 (2020).

J. Zhu, S. Li, L. Shen, W. Yang, and L. Zhou, Trans. Nonferrous Met. Soc. China 27, 1096–1104 (2017).

J. Li, G. Huang, X. Mi, L. Peng, H. Xie, and Y. Kang, Materials (Basel) 12, 2076 https://doi.org/10.3390/ma12132076 (2019).

S.P. Tao, Z.L. Lu, L. Jia, H. Xie, and J.L. Zhang, Mater. Res. Express 7, 066520 https://doi.org/10.1088/2053-1591/ab9a7d (2020).

J. Li, G. Huang, X. Mi, L. Peng, H. Xie, and Y. Kang, Materials (Basel) 12, 2855 https://doi.org/10.3390/ma12182855 (2019).

Y.K. Wu, Y. Li, J.Y. Lu, S. Tan, F. Jiang, and J. Sun, Mat. Sci. Eng. A-Struct. 731, 403–412 https://doi.org/10.1016/j.msea.2018.06.075 (2018).

R. Monzen, and C. Watanabe, Mat. Sci. Eng. A-Struct. 483–84, 117–119 https://doi.org/10.1016/j.msea.2006.12.163 (2008).

Q. Lei, S.Y. Li, J.L. Zhu, Z. Xiao, F.F. Zhang, and Z. Li, Mater. Charact. 147, 315–323 https://doi.org/10.1016/j.matchar.2018.11.018 (2019).

E. Lee, S. Han, K. Euh, S. Lim, and S. Kim, Met. Mater. Int. 17, 569–576 https://doi.org/10.1007/s12540-011-0807-7 (2011).

W. Wang, E.Y. Guo, Z.N. Chen, H.J. Kang, Z.J. Chen, C.L. Zou, R.G. Li, G.M. Yin, and T.M. Wang, Mater. Charact. 144, 532–546 https://doi.org/10.1016/j.matchar.2018.08.003 (2018).

S.Z. Han, J.H. Gu, J.H. Lee, Z.P. Que, J.H. Shin, S.H. Lim, and S.S. Kim, Met. Mater. Int. 19, 637–641 https://doi.org/10.1007/s12540-013-4002-x (2013).

Z.L. Zhao, Z. Xiao, Z. Li, W.T. Qiu, H.Y. Jiang, Q. Lei, Z.R. Liu, Y.B. Jiang, and S.J. Zhang, Mat. Sci. Eng. a-Struct. 759, 396–403 https://doi.org/10.1016/j.msea.2019.05.003 (2019).

J.Z. Huang, Z. Xiao, J. Dai, Z. Li, H.Y. Jiang, W. Wang, and X.X. Zhang, Mat Sci Eng a-Struct 744, 754–763 https://doi.org/10.1016/j.msea.2018.12.075 (2019).

C. Wang, H. Fu, H. Zhang, X. He, and J. Xie, Mater. Sci. Eng. A 838, 142815 https://doi.org/10.1016/j.msea.2022.142815 (2022).

Y. Wu, Y. Li, J. Lu, S. Tan, F. Jiang, and J. Sun, Mater. Sci. Eng., A 742, 501–507 https://doi.org/10.1016/j.msea.2018.11.045 (2019).

Y.J. Ban, Y.F. Geng, J.R. Hou, Y. Zhang, M. Zhou, Y.L. Jia, B.H. Tian, Y. Liu, X. Li, and A.A. Volinsky, J. Mater. Sci. Technol. 93, 1–6 https://doi.org/10.1016/j.jmst.2021.03.049 (2021).

Y. Lin, and X.-M. Chen, Mater. Des. 32, 1733–1759 (2011).

X. Shen, D. Zhang, C. Yao, L. Tan, and X. Li, Mater. Today Commun. 31, 103772 (2022).

K.H. Sim, Y.C. Ri, C.H. Jo, O.J. Kim, R.S. Kim, and H. Pak, Vacuum 210, 111749 (2023).

W.N. Chen, S.J. Li, K.S. Bhandari, S. Aziz, N. Kosimov and D.W. Jung, In Materials Science Forum, (Trans Tech Publ: 2022), pp 3–10.

D. Samantaray, S. Mandal, and A. Bhaduri, Comput. Mater. Sci. 47, 568–576 (2009).

W. Peng, W. Zeng, Q. Wang, and H. Yu, Mater. Des. 51, 95–104 (2013).

A. Abbasi-Bani, A. Zarei-Hanzaki, M. Pishbin, and N. Haghdadi, Mech. Mater. 71, 52–61 (2014).

W. Xu, L. Zhou, X. Zhu, and W.-T. Qiu, Trans. Nonferrous Metals Soc. China 30, 2737–2748 (2020).

S.-H. Song, Materials 13, 3766 (2020).

P. Wan, H. Zou, K. Wang, and Z. Zhao, Met. Mater. Int. 27, 4235–4249 (2021).

D. Xue, W. Wei, W. Shi, X. Zhou, L. Rong, S. Wen, X. Wu, P. Qi, K. Gao, H. Huang, and Z. Nie, Mater. Today Commun. 32, 104076 https://doi.org/10.1016/j.mtcomm.2022.104076 (2022).

G.L. Ji, Q. Li, K.Y. Ding, L. Yang, and L. Li, J. Alloy. Compd. 648, 397–407 https://doi.org/10.1016/j.jallcom.2015.06.264 (2015).

R.L. Goetz, and S.L. Semiatin, J. Mater. Eng. Perform. 10, 710–717 https://doi.org/10.1361/105994901770344593 (2001).

R. Ebrahimi, and A. Najafizadeh, J. Mater. Process. Technol. 152, 136–143 https://doi.org/10.1016/j.jmatprotec.2004.03.029 (2004).

Y. Han, G.J. Qiao, J.P. Sun, and D.N. Zou, Comput. Mater. Sci. 67, 93–103 https://doi.org/10.1016/j.commatsci.2012.07.028 (2013).

K. Song, Z. Li, M. Fang, Z. Xiao, Y. Zhu, and Q. Lei, Mater. Sci. Eng., A 845, 143178 (2022).

Y. Zhu, Z. Xiao, Z. Li, K. Song, Q. Lei, and Y. Chen, JOM 74, 4352–4359 (2022).

Y. Ban, Y. Zhang, Y. Jia, B. Tian, A.A. Volinsky, X. Zhang, Q. Zhang, Y. Geng, Y. Liu and X. Li, Materials and Design, 191, 108613 (2020). https://doi.org/10.1016/j.matdes.2020.108613

F. Liu, J. Ma, L. Peng, G. Huang, W. Zhang, H. Xie, and X. Mi, Materials 13, 2042 (2020).

P. Yong, X. Zhu, J. Yanlin, Z. Rui, Y. Jiang, Q. Wenting, and L. Zhou, J. Alloys Compd. 845, 156161 https://doi.org/10.1016/j.jallcom.2020.156161 (2020).

Z. Zhao, Z. Li, Z. Xiao, M. Ma, and K. Song, JOM 73, 2274–2284 (2021).

Y. Geng, X. Li, H. Zhou, Y. Zhang, Y. Jia, B. Tian, Y. Liu, A.A. Volinsky, X. Zhang, K. Song, G. Wang, L. Li, and J. Hou, J. Alloys Compd 821, 153518 https://doi.org/10.1016/j.jallcom.2019.153518 (2020).

Y. Geng, Y. Zhang, K. Song, Y. Jia, X. Li, H.-R. Stock, H. Zhou, B. Tian, Y. Liu, A.A. Volinsky, X. Zhang, P. Liu, and X. Chen, J. Alloys Compd. 842, 155666 https://doi.org/10.1016/j.jallcom.2020.155666 (2020).

T. Wang, Y. Chen, B. Ouyang, X. Zhou, J. Hu, and Q. Le, Mater Sci Eng A 816, 141259 https://doi.org/10.1016/j.msea.2021.141259 (2021).

U.M. Chaudry, R. Jaafreh, A. Malik, T.-S. Jun, K. Hamad, and T. Abuhmed, Mathematics 10, 766 (2022).

J.F. Durodola, Prog. Mater Sci. 123, 100797 https://doi.org/10.1016/j.pmatsci.2021.100797 (2022).

S. Li, W. Chen, K.S. Bhandari, D.W. Jung, and X. Chen, Materials 15, 3788 (2022).

L. Kanthi, P. Wankhede, S. Kurra, S.K. Singh, and S. Geetha Rajashekharan, J Mater Eng Perform 32, 462–474 https://doi.org/10.1007/s11665-022-07102-x (2023).

A. Anitha Lakshmi, C. Srinivasa Rao, J. Gangadhar, C. Srinivasu, and S.K. Singh, Mater Today Proc 4, 946–956 https://doi.org/10.1016/j.matpr.2017.01.106 (2017).

Y.V.R.K. Prasad, J. Mater. Eng. Perform. 12, 638–645 https://doi.org/10.1361/105994903322692420 (2003).

Y. Ban, Y. Zhang, B. Tian, Y. Jia, K. Song, X. Li, M. Zhou, Y. Liu, and A.A. Volinsky, Materials 13, 3186 (2020).

P. Yang, M. Zhou, Y. Zhang, Y. Jia, B. Tian, Y. Liu, X. Li, and A.A. Volinsky, Mater Charact 181, 111502 https://doi.org/10.1016/j.matchar.2021.111502 (2021).

Y. Geng, X. Li, Y. Zhang, Y. Jia, H. Zhou, B. Tian, Y. Liu, A.A. Volinsky, X. Zhang, K. Song, P. Liu, and X. Chen, Vacuum 177, 109376 https://doi.org/10.1016/j.vacuum.2020.109376 (2020).

Acknowledgements

The authors acknowledge the financial support from the National Key Research and Development Program of China (Grant No. 2021YFB3700700), the Key Technologies R&D Program of Yunnan Province (Grant No. 202102AB080019-1) and the Projects of State Key Laboratory of Powder Metallurgy, Central South University, Changsha, China. The authors are also grateful for the Hunan Navi New Materials Technology and the High Performance Computing Center of Central South University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, M., Xiao, Z., Li, Z. et al. Hot Deformation and Microstructure Evolution of a Cu-Ni-Co-Si-Cr-Mg Alloy. JOM 75, 3083–3096 (2023). https://doi.org/10.1007/s11837-023-05848-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05848-w