Abstract

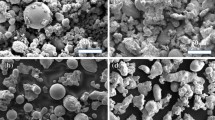

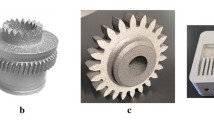

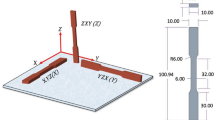

The 25Cr7Ni stainless steel is characterized by its two-phase microstructure consisting of ferrite and austenite, contributing to an excellent combination of mechanical and corrosion properties. The present study examined the effects of laser energy density and laser powder bed fusion (L-PBF) process parameters on the physical, mechanical and corrosion properties of a water atomized 25Cr7Ni stainless steel powder processed through L-PBF. The results from the study saw that a combination of L-PBF process parameters (laser scan speed and laser scan spacing at a constant layer thickness) as critical factors affecting the mechanical and corrosion properties of the printed samples. The Archimedes density, mechanical and corrosion properties of samples improved with increase in energy density. The as-printed samples displayed single-phase ferritic microstructure and higher mechanical strength (1050 MPa) compared to wrought, metal injection molded (MIM), powder metallurgically sintered (PM) 25Cr7Ni stainless steel (super duplex stainless steel) alloys. The samples exhibited comparable corrosion resistance to that of a wrought 25Cr7Ni stainless steel despite the presence of only ferritic microstructure.

Similar content being viewed by others

References

F. Hengsbach, P. Koppa, K. Duschik, M.J. Holzweissig, M. Burns, J. Nellesen, W. Tillmann, T. Tröster, K.P. Hoyer, and M. Schaper, Mater. Des. 133, 136 (2017).

H. Irrinki (Electronic Thesis and Dissertations, 2018). https://doi.org/10.18297/etd/3024.

K.P. Davidson and S.B. Singamneni, Rapid Prototyp. J. 23, 1146 (2017).

S. D. Nath (Electronic Thesis and Dissertations, 2018). https://doi.org/10.18297/etd/3074

D. Gu, Laser Addit. Manuf. High-Performance Mater. 1 (2015). https://doi.org/10.1007/978-3-662-46089-4

R.N. Gunn, Duplex Stainless Steels Microstructure, Properties and Applications (Woodhead Publishing, 1998).

R. N. B. T.-D. S. S. Gunn, editors, in Woodhead Publishing Series in Metals and Surface Engineering (Woodhead Publishing, 1997), pp. 24–49.

I. Raffeis, U. Vroomen, F. Adjei-Kyeremeh, D. Großmann, H. Hammelrath, E. Westhoff, S. Bremen, D. Boscolo Bozza, and A. Bührig-Polaczek, Materwiss. Werksttech. (2020). https://doi.org/10.1002/mawe.201900136

K. Saeidi, L. Kevetkova, F. Lofaj, and Z. Shen, Mater. Sci. Eng. A 665, 59 (2016).

S. Hoeges, A. Zwiren, and C. Schade, Met. Powder Rep. 72, 111 (2017).

K. Riener, N. Albrecht, S. Ziegelmeier, R. Ramakrishnan, L. Haferkamp, A. B. Spierings, and G. J. Leichtfried, Addit. Manuf. (2020). https://doi.org/10.1016/j.addma.2020.101286

N.T. Aboulkhair, N.M. Everitt, I. Ashcroft, and C. Tuck, Addit. Manuf. 1, 77 (2014).

L. A. Dobrzañski, Z. Brytan, M. A. Grande, and M. Rosso, Arch. Mater. Sci. Eng. 28, 217–223 (2007).

J. C. Lippold, Welding Metallurgy and Weldability (2014).

A. D. Iams, J. S. Keist, and T. A. Palmer, Metall. Mater. Trans. A Phys. Metall. Mater. Sci. (2020). https://doi.org/10.1016/j.msea.2020.139806

K. Mansouri, K. Ibrik, N. Bensalah, and A. Abdel-Wahab, Ind. Eng. Chem. Res. (2011). https://doi.org/10.1021/ie201206d

G. T. Burstein and P. C. Pistorius, Corrosion (1995). https://doi.org/10.5006/1.3293603

G. T. Burstein, P. C. Pistorius, and S. P. Mattin, Corros. Sci. (1993). https://doi.org/10.1016/0010-938X(93)90133-2

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest towards this research article and this research received no external funding.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Arumugham Akilan, A., Gal, C.W., Nath, S.D. et al. Properties of Water Atomized 25Cr7Ni Stainless Steel Processed by Laser-Powder Bed Fusion. JOM 75, 1710–1720 (2023). https://doi.org/10.1007/s11837-023-05771-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05771-0