Abstract

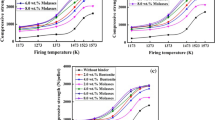

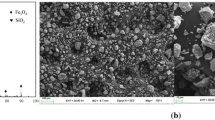

To replace part of sinter with pellets to achieve energy saving and emission reduction, high-basicity pellets are investigated. In this study, the effect of basicity and roasting temperature on the compressive strength and microstructure during the induration is examined. Green pellets (basicity: 1.5–3.5) are made by laboratory-scale balling disc and roasted in a tube furnace. Thermogravimetric analysis (TG) is used to analyze the thermal decomposition of mixed raw materials with different basicity. The x-ray diffraction (XRD), scanning electron microscope and energy-dispersive spectroscopy (SEM–EDS) are used to systematically analyze the phase composition, microstructure and elemental distribution of pellets with different basicity. The findings show that as the basicity increases, weightlessness of green pellets becomes intense, and the porosity increases at 1190°C. At other roasting temperatures, the porosity first increases and then decrease. The law of compressive strength is opposite to that of porosity. When the temperature is raised, the generation of molten phase is promoted and fills the pores, which reduces porosity. With the increase of basicity, CaO reacts with Fe2O3 to form CaFe2O4 and Ca2Fe2O5. Depending on the experimental results, a schematic of the oxidation mechanism is presented, providing the theoretical foundations for the study of high-basicity pellets.

Similar content being viewed by others

References

J. Fang, R.J. Gong, L.S. Zhao, and H. Meng, Iron Steel 49, 66 (2007).

P. Ranjan and J. Pal, Iron Steel 43, 688 (2016).

X.D. Xing, J.L. Zhang, Y.R. Liu, Z.J. Liu, and N.Y. Li, Chin. J. Eng. 38, 1227 (2016).

J.U. Jiantao, W. Liu, X. Xing, J. Yao, and G. Jiao, Chin. J. Process Eng. 117, 207 (2019).

W. Xia and W. Xingliang, Min. Eng. 17, 1 (2019).

W. Weixing, Metall. Manag. 09, 53 (2018).

X. Manxing and Z. Yulan, Sinter. Group 42, 25 (2017).

H. Wuestner, Zem Kalt Gips 12, 725 (1985).

X. Yang, D. Zhang, K. Liu, F. Xing, and H. Jinling, J. Eng. Stud. 09, 44 (2017).

K. Bai, L. Liu, Y. Pan, H. Zuo, and Q. Xue, Ironmak Steelmak 48, 1 (2021).

T. Umadevi, P. Kumar, N.F. Lobo, M. Prabhu, P.C. Mahapatra, and M. Ranjan, ISIJ Int. 51, 14 (2011).

S. Dwarapudi, T.K. Ghosh, A. Shankar, V. Tathavadkar, D. Bhattacharjee, and R. Venugopal, Int. J. Miner. Process. 96, 45 (2010).

M. Onoda, O. Tsuchiya, T. Sugiyama, and I. Fujita and quality improvements of lime fluxed pellets, in Paper Presented at ISS-AIME 40th Iron Making Conference, Toronto, Canada, (1980), pp. 286–298.

K.H. Li, Study on preparation and application technology of high basicity pellets in TISCO (PhD thesis ,University of Science and Technology Beijing, 2020). https://kns.cnki.net/KCMS/detail/detail.aspx?dbname=CDFDLAST2020&filename=1020109185.nh.

S. Dwarapudi, T.K. Ghosh, A. Shankar, V. Tathavadkar, D. Bhattacharjee, and R. Venugopal, Int. J. Miner. Process. 99, 43 (2011).

S.C. Panigrahy, B.C. Jena, and M. Rigaud, Metall. Mater. Trans. B. 21, 463 (1990).

F.W. Frazer, H. Westenberger, K.H. Boss, and W. Thumm, Int. J. Miner. Process. 2, 353 (1975).

L. Bentell, Scand. J. Metall. 10, 205 (1981).

L. Bentell, L. Norrman, and M. Sundgren, Scand. J. Metall. 13, 308 (1984).

D. Zhu, T. Chun, J. Pan, and J. Zhang, Int. J. Miner. Process. 125, 51 (2013).

J. Li, H.F. An, W.X. Liu, A.M. Yang, and M.S. Chu, J. Iron Steel Res. Int. 27, 239 (2019).

M.K. Mohanty, S. Mishra, B. Mishra, and S. Sarkar, Arab. J. Sci. Eng. 43, 1 (2018).

Z. Yang, Z. Liu, M. Chu, L. Gao, C. Feng, and J. Tang, ISIJ Int. 61, 1431 (2021).

R.K. Dishwar, A.K. Mandal, and O.P. Sinha, Metall. Mater. Trans. B 50, 617 (2019).

J.J. Friel and E.S. Erickson, Metall. Trans. B 11, 233 (1980).

A.K. Mandal, A. Sarkar, and O.P. Sinha, J. Inst. Eng. (India) 91, 69 (2016).

R.K. Dishwar and O.P. Sinha, Fuel 296, 120640 (2021).

D. Zhu, D. Wang, and J. Pan, ISIJ Int. 62, 632 (2022).

H.M. Long, Sintering Principle and Technology of Iron ore Powder (Metallurgical Industry Press, Beijing, 2010), pp64–65.

Y.M. Zhang, Pellets Production Technology (Metallurgical Industry Press, Beijing, 1998), p66.

R.C. Hao, L. Liu, X.L. Han, Y.F. Wang, C. Zhang, and L.H. Wang, Iron Steel Vanadium Titanium 42, 111 (2021).

Acknowledgements

The present work was financially supported by the National Nature Science Foundation of China [grant no. 2019M663932XB (52174325)] and the Natural Science Basic Research Program of Shaanxi (program no. 2019JLP-05).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ju, JT., Li, QD., Xing, XD. et al. Investigations on Compressive Strength and Microstructure of High-Basicity Iron Ore Pellets. JOM 75, 2525–2534 (2023). https://doi.org/10.1007/s11837-023-05747-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-023-05747-0